Improved hydrolytic acidification tank

A technology for hydrolysis and acidification tank and water inflow, applied in the field of sewage treatment and environmental protection, can solve the problems of reducing the effective contact between activated sludge and sewage, reducing the effect of pollutant removal, lack of sludge return system, etc., and achieving complete hydrolysis and acidification. , the effect of high activated sludge concentration, sludge concentration and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

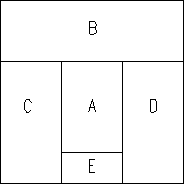

[0018] Example 1, the improved hydrolysis acidification tank, the influent mixing zone A, the sludge return and the discharge zone E are arranged up and down to connect with the sludge return device, and a sequence of batch processing zones C and D are respectively set on both sides. The sequence batch treatment area alternates with the second stirring reaction area and the static sedimentation area; the first stirring reaction area B is set at the horizontal end of the water inlet mixing area A, sequence batch processing area C, and D, and the first stirring reaction area B They are respectively connected to the water inlet mixing area A, the two-sequence batch processing area C, and D; the two-sequence batch processing areas C and D are equipped with a stirring device, a water outlet device and a mud outlet device, and the mud outlet device is connected to the sludge return flow with discharge zone E.

[0019] There is a stirring device in the water inlet mixing area A, and ...

Embodiment 2

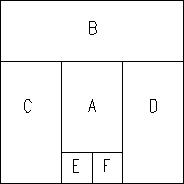

[0023] Example 2, with reference to Example 1, two side-by-side sludge return and discharge areas E and F are arranged below the influent mixing area A, which are respectively connected with the mud outlets of the adjacent sequence batch processing areas C and D. Sludge return and discharge areas E and F are equipped with sludge return devices connected to the water inlet mixing area A, and also have their own sludge discharge pipes.

[0024]The first period: Turn on the stirring device in the water inlet mixing zone A, the first stirring reaction zone B, the sludge return and discharge zone E, and the water outlet device in the sequence batch treatment zone C, and close the sequence batch treatment zone C The stirring device and the sludge return device in the sludge return and discharge area F allow the sewage to enter the water inlet mixing area A, fully mix with the returned activated sludge and enter the first stirring reaction area B for hydrolysis and acidification react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com