Method for producing food grade enzyme preparation by using compound decolorizing agent

A decolorizing agent and enzyme preparation technology, applied in food preparation, biochemical equipment and methods, enzymes, etc., can solve the problems of poor light transmittance, impurities contained in enzymes, deep color of enzyme preparations, etc., to improve color and purity , improve the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

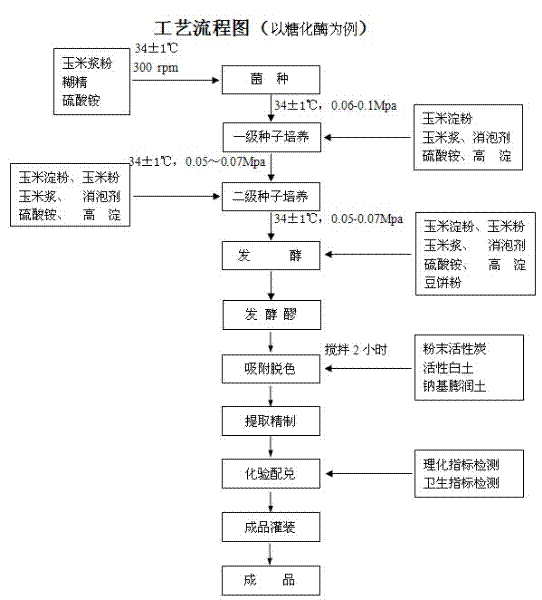

[0013] 1. Preparation of fermented mash: Microorganisms are cultivated by strains, and after maturity, they are inserted into the first-level seed tank for cultivation. A mature fermented mash is obtained.

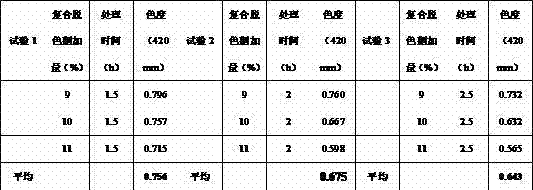

[0014] 2. Adsorption decolorization: The weight components of this composite decolorizer are as follows:

[0015] Powdered Activated Carbon, 2 parts,

[0016] activated clay, 1 part,

[0017] Sodium bentonite, 7 parts.

[0018] Put the mature fermented mash into the pretreatment tank, measure the volume of the fermented mash in the tank (the usage amount of the compound decolorizer, add 10 kilograms of the compound decolorizer by every 100 liters of fermented mash, calculate the powder activated carbon, activated clay and sodium-based bentonite), start stirring, and then add powdered activated carbon, activated clay and sodium-based bentonite in a stirring state, stir fully for 2 hours, and control the temperature of the mash to 36 degrees. After the decolorization tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com