Washing machine water level automatic control system based on water inlet quantity detection and washing machine water level automatic control method

An automatic control system and water intake technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of impossibility and poor control effect, achieve precise control, good laundry effect, and improve control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

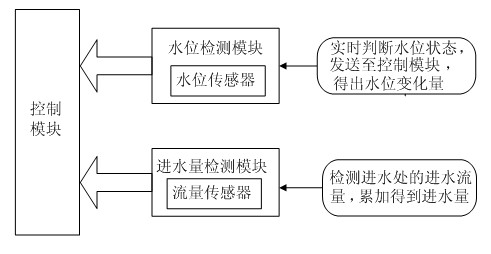

[0046] Such as figure 1 As shown, this example provides an automatic water level control system for washing machines based on water inflow detection, including:

[0047] The control module is used to realize the automatic control of the water level of the washing machine;

[0048] The water level detection module uses a water level sensor to detect the state of the water level in real time, obtains the corresponding water level change, and sends the water level change to the control module;

[0049] The water inflow detection module uses a flow sensor to detect the water inflow at the water inlet in real time, and calculates the inflow by accumulating the water inflow and sends it to the control module;

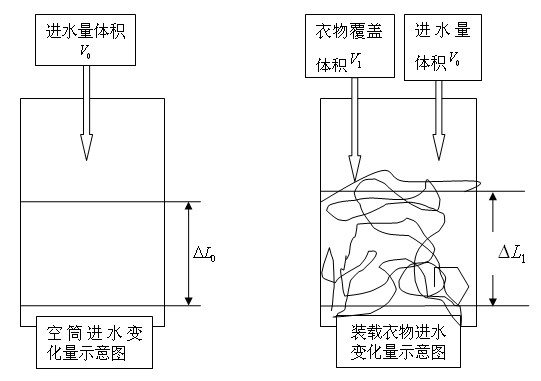

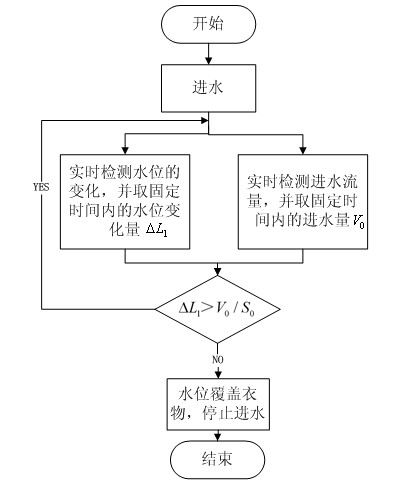

[0050] Wherein, the control module includes a comparison unit, and the comparison unit is used for comparing the variation of the water level of the empty cylinder with the variation of the loading water level after loading the clothes, until the variation of the loading wat...

Embodiment 2

[0063] The difference from Embodiment 1 is that the control module described in this embodiment uses an MCU to realize automatic control of the water level of the washing machine.

[0064] This example further adopts the above-mentioned technical solution, which has the advantage of detecting the inflow of water added to the washing machine through the flow sensor, detecting the change of the water level in the washing machine in real time through the water level sensor, and using the MCU to calculate the relationship between the change in water level and the change in water inflow. Judging when the water level has just covered the clothes, in order to achieve precise control of the relationship between the water level and the clothes.

Embodiment 3

[0066] The difference from Embodiment 2 is that the water inflow detection module described in this example uses a single-chip microcomputer to accumulate the inflow flow to obtain the inflow and send it to the control module.

[0067] Wherein, the water inflow rate is real-time detected water inflow data, and by accumulating the real-time data within a fixed time period, the total water inflow volume within the time period can be obtained.

[0068] This example further adopts the above-mentioned technical solution, and its advantage is that the flow sensor is introduced, and through its cooperation with the single-chip microcomputer, the actual water injection volume in the washing machine can be detected, that is, the change of water inflow, and the water level sensor is used to check the real-time change of the water level , if the clothes are completely covered by water, the change in the loading water level is the same as the change in the water level of the empty bucket, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com