Method for supporting deep foundation pit

A deep foundation pit support and deep pit foundation technology, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve problems such as large quality differences, poor bending resistance, and difficulty in meeting requirements, and increase bending resistance , meet technical needs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

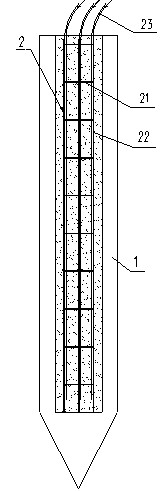

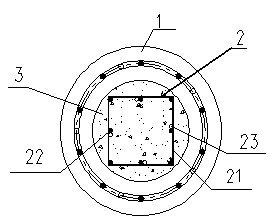

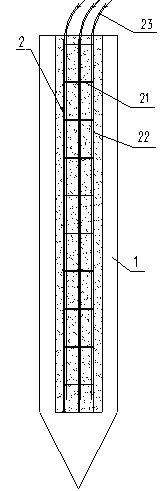

[0019] The following is attached with the manual figure 1 , attached figure 2 The present invention is further described.

[0020] The method is as follows:

[0021] (1) Driving hollow pipe piles: According to the design drawings, hammer or static pressure method is used to drive a number of prestressed hollow pipe piles 1 with closed pile tip pretensioning method around the foundation pit.

[0022] (2) Reinforcement: Put the reinforcement cage 2 inside the hollow pipe pile 1 and fix it. The reinforcement cage 2 is composed of 10 square (or round) stirrups 21 and 8 main reinforcements 22 evenly arranged vertically on the stirrups. , 4 grouting pipes 23 are evenly bundled on the main reinforcement 22, and the upper end of the grouting pipe 23 exceeds the upper end of the pipe pile, and the wall of the grouting pipe 23 corresponding to the steel cage 2 is provided with a plurality of grouting holes along the length direction ( Not shown in the figure), the outside of the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com