Underground floating valve with high-temperature resistance, high-pressure resistance and corrosion resistance

A corrosion-resistant and high-temperature-resistant technology, applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as high bottomhole temperature, high bottomhole pressure, and downhole accidents, and achieve The effects of increasing working life, preventing overvoltage damage, and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

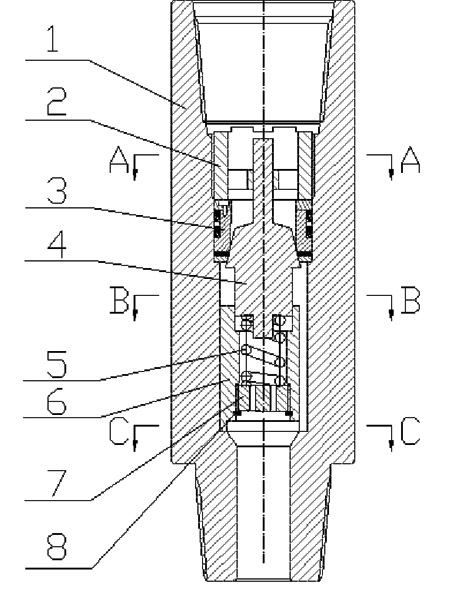

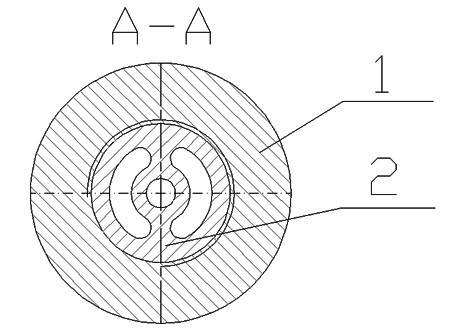

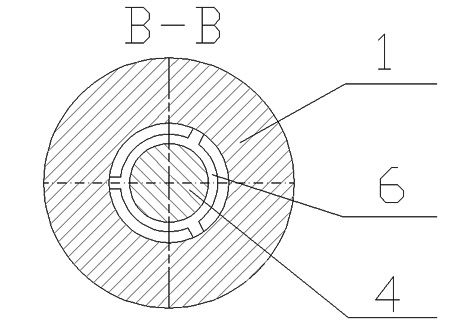

[0021] combined with Figure 1-4 , to further describe the present invention:

[0022] The present invention consists of a valve body 1, a valve core sleeve 2, a sealing assembly 3, a valve core 4, a spring 5, a valve seat 6, a spring plug 7, and a plug positioning ring 8. The valve core sleeve 2, The sealing assembly 3 and the valve seat 6 are assembled inside the valve body 1; the spring plug 7 and the plug positioning ring 8 are installed on the valve seat 6; the return spring 5 is located between the valve core 4 and the spring plug 7; The upper shaft of the valve core 4 is installed in the valve core pressure sleeve 2 , the taper surface is in contact with the sealing assembly 3 , the lower shaft is installed in the inner cavity of the valve seat 6 , and the bottom surface is in contact with the return spring 5 .

[0023] The valve body 1 is the mother body of the entire float valve, and other accessories are installed in the valve body 1; the upper and lower parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com