Full-length anchoring supporting method with intensive resin anchor rod and anchor-shotcrete net

It is a technology of solid-intensive, sprayed anchor mesh, which is applied in the installation of bolts, earth-moving drilling, wellbore lining, etc. It can solve the problems that the supporting effect cannot meet the requirements, the mining production cannot be satisfied, and the ore body cannot be fully recovered. , to achieve the effect of preventing roadway deformation and prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The full-length anchoring-intensive resin bolt spraying anchor mesh support method of the present invention comprises the following steps:

[0028] A. Carry out drainage and floating operation after the roadway blasting, so that there is no pumice on the rock surface, so as to ensure the safety of the operators and the quality of the sprayed concrete in the roadway;

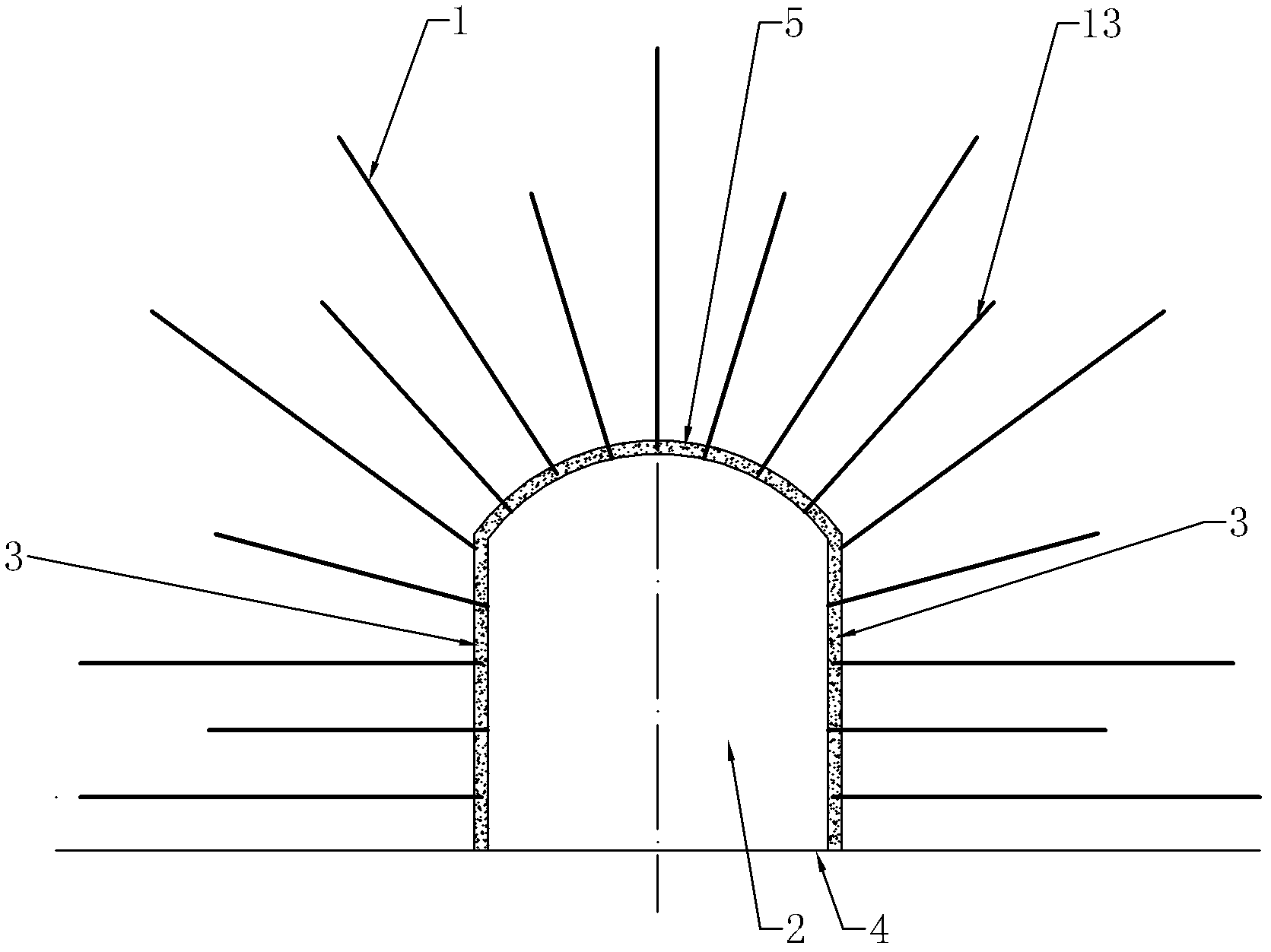

[0029] B. Carry out the initial 50 mm plain material spraying concrete on the roadway;

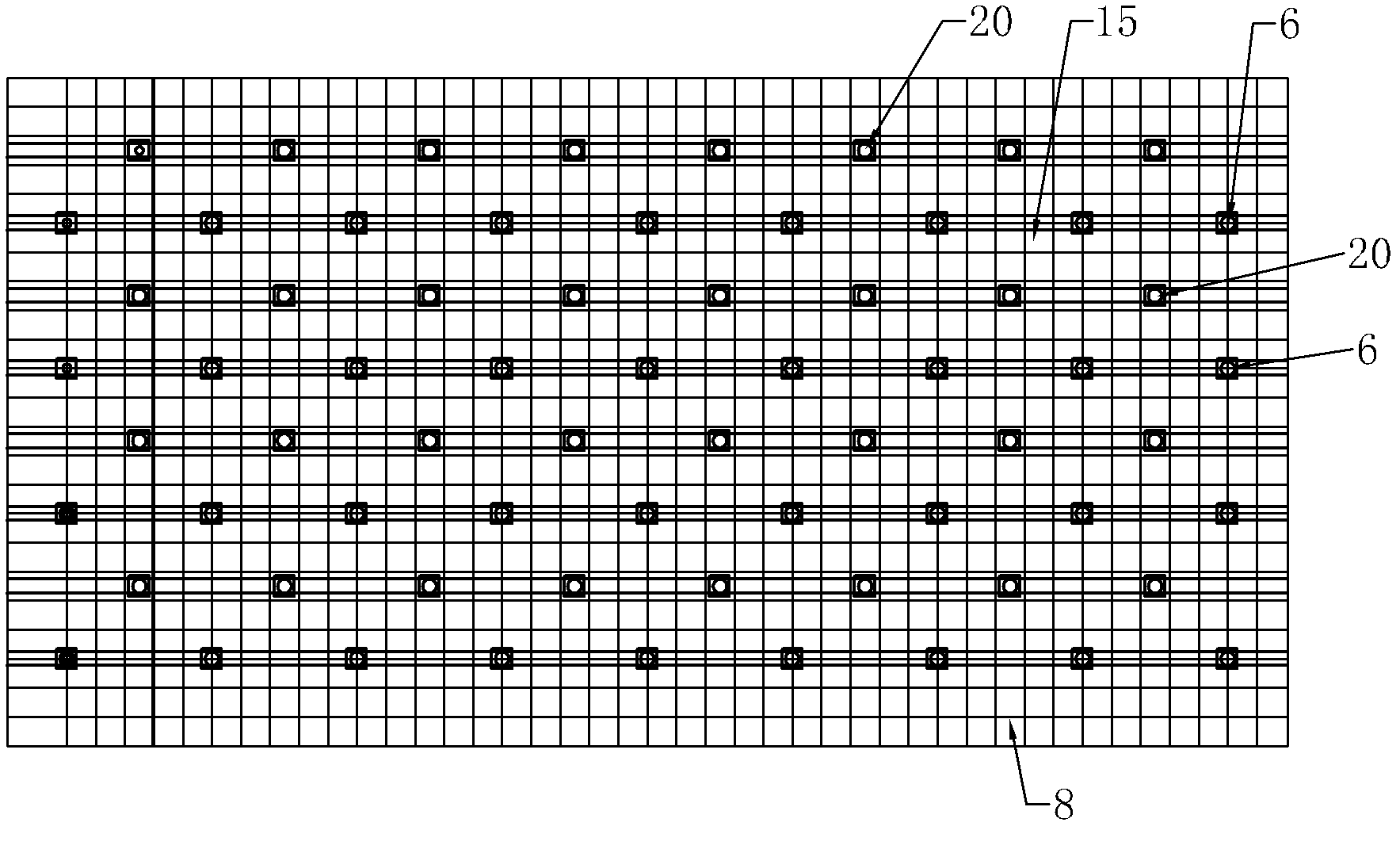

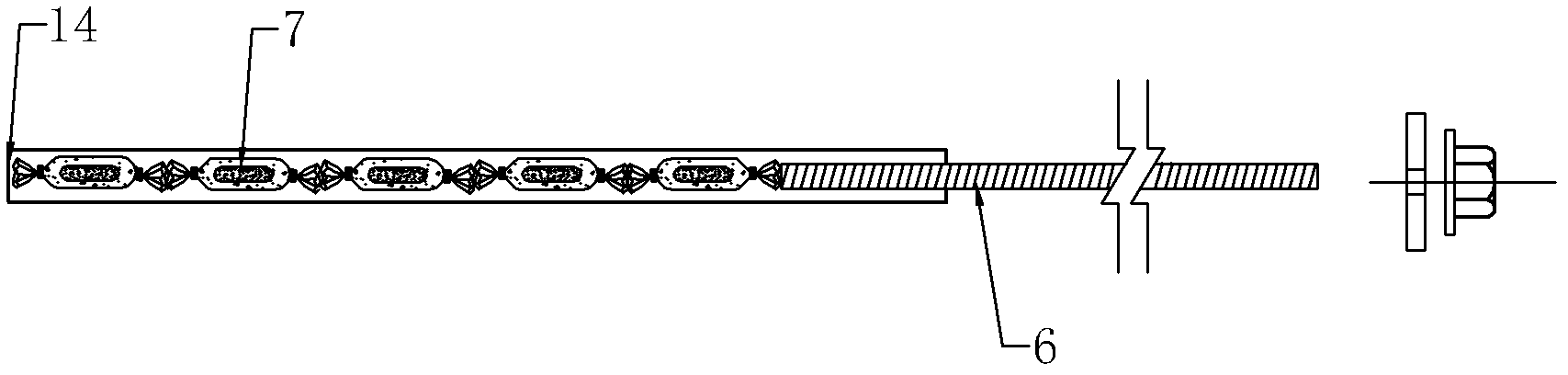

[0030] C. For the construction of the main anchor hole, use a ∮32 mm drill bit to drill the main anchor hole. The depth of the main anchor hole is 2370 mm, so that the length of the main anchor exposed from the anchor hole cannot exceed 150 mm. When constructing the main bolt hole, several rows of main bolt hole groups are drilled perpendicular to the rock wall of the roadway, such as figure 1 As shown, each row of main anchor hole groups includes nine main anchor holes 1, and is located on the same cross-section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com