Energy efficiency analysis method for pump operation in industrial circulating water system

A technology of industrial circulating water and analysis methods, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve the problem of difficulty in judging the operating state of the pump set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

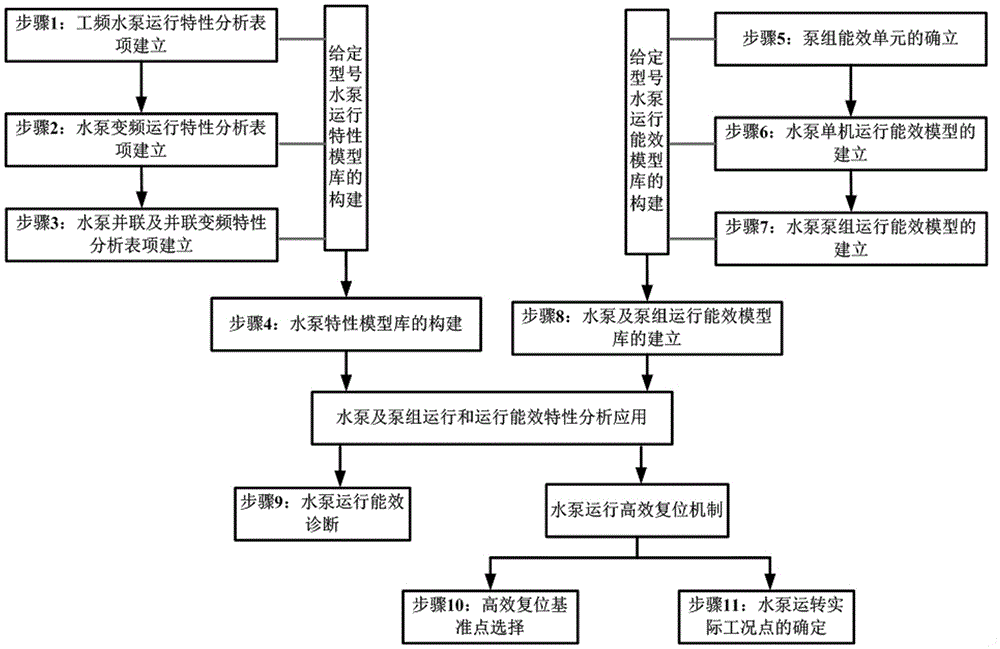

[0077] Embodiment: the basic process of water pump characteristic model storehouse and water pump characteristic model storehouse establishment is as follows:

[0078] A1. Establishment of pump characteristic model library;

[0079] Step 1: Establishment of the analysis table items for the operation characteristics of the water pump in power frequency operation;

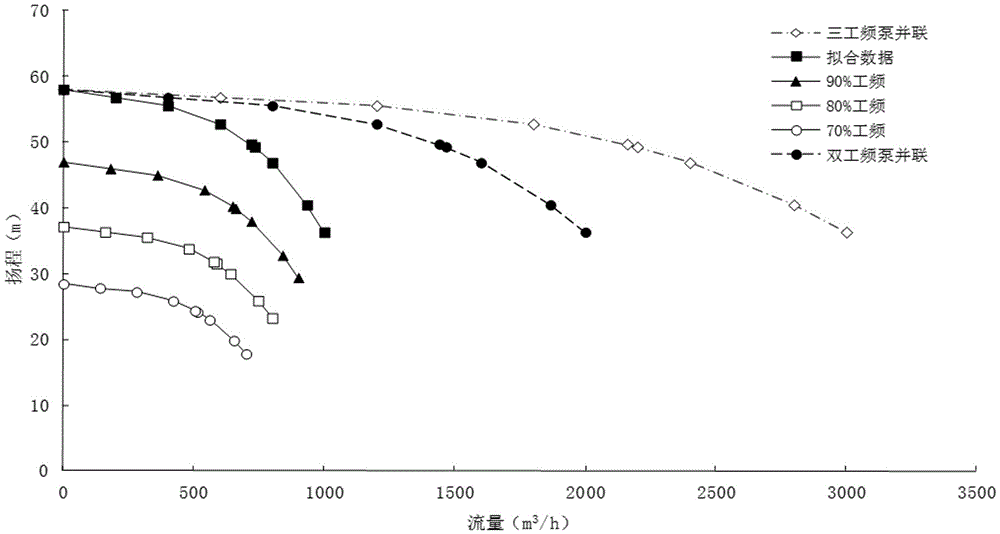

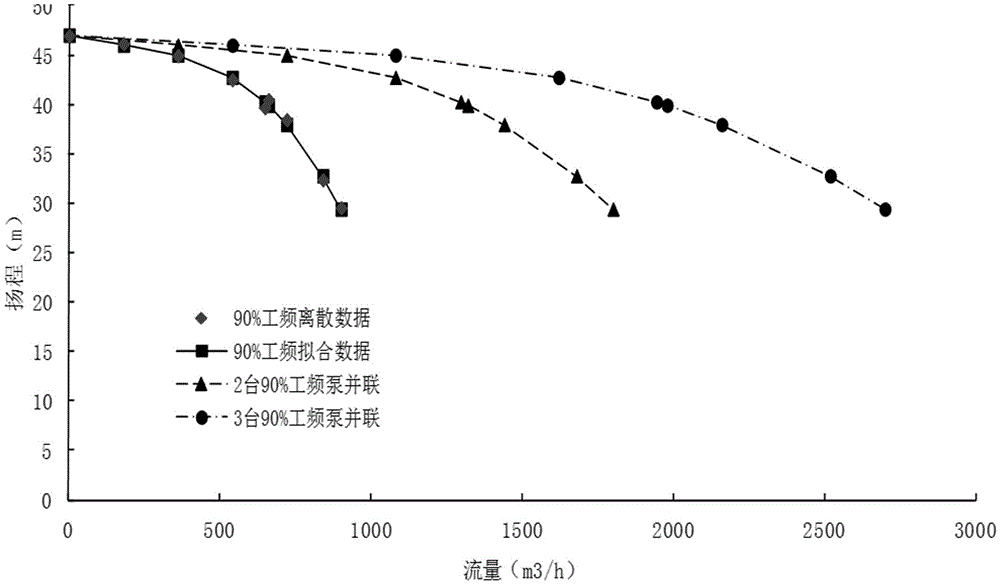

[0080] The establishment of the power frequency operation characteristic analysis model and the corresponding table items is the basis for the single-unit operation of the pump and the analysis of the operation characteristics of the pump group under the condition of variable working conditions. In the information system, the establishment of the pump characteristic model library is based on the pump operation characteristic model. Therefore, it is first necessary to establish an explicit model for the analysis of the power frequency operation characteristics of the pump. In the actual operation process, the analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com