Energy-saving electric pump and working method thereof

A technology of electric pumps and motors, which is applied in the direction of pumps, pump control, pump devices, etc., can solve the problems of interruption of oil delivery operations, lower work efficiency, lower oil delivery flow, etc., to achieve rapid oil delivery, reduce labor intensity, Solve the effect of air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

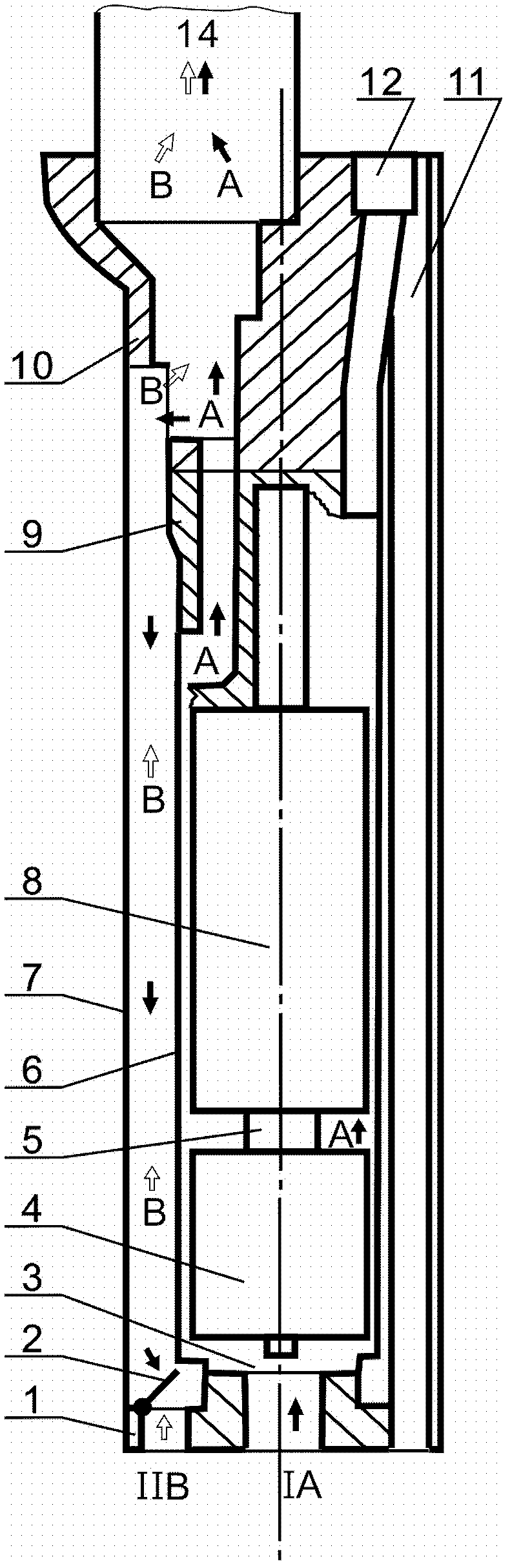

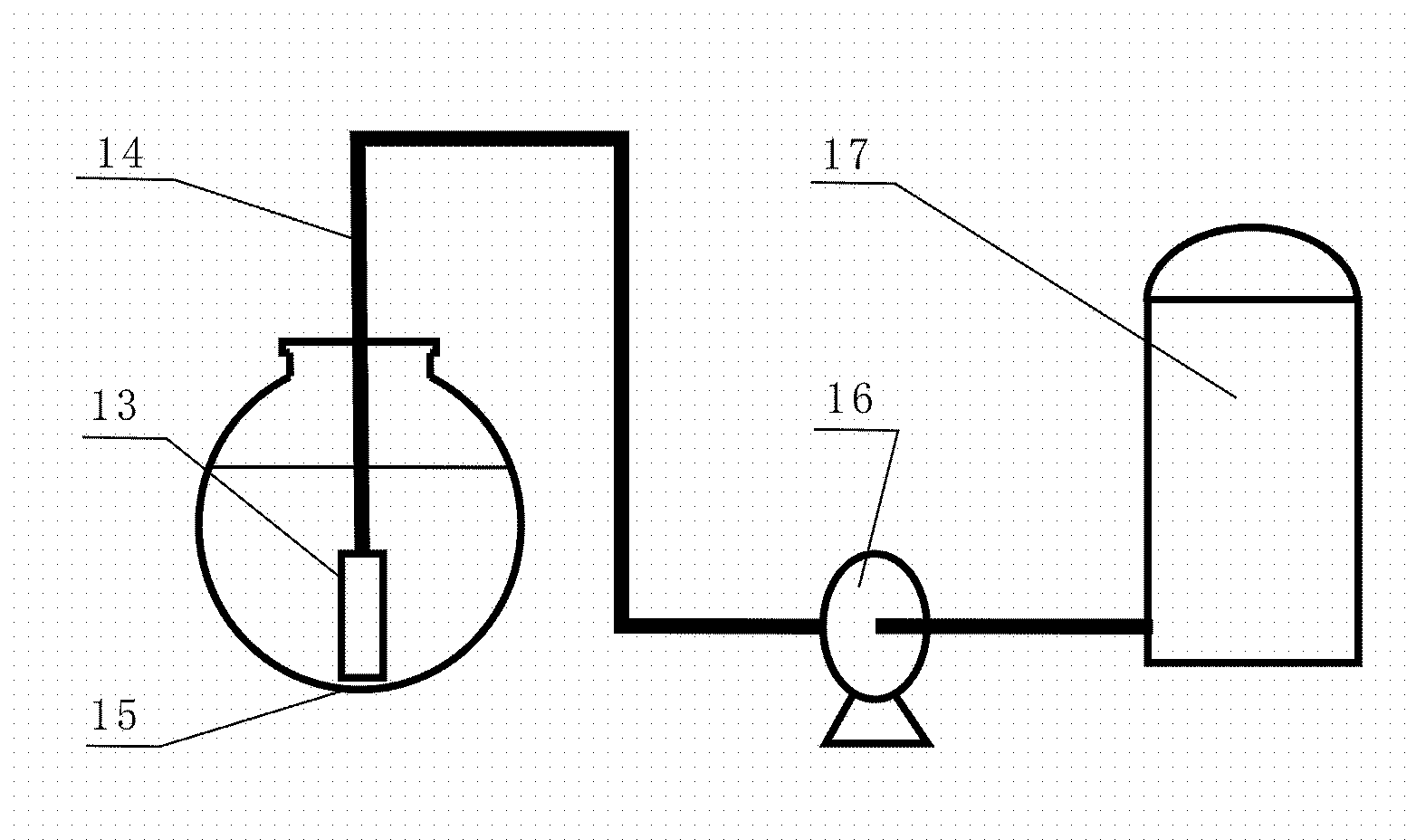

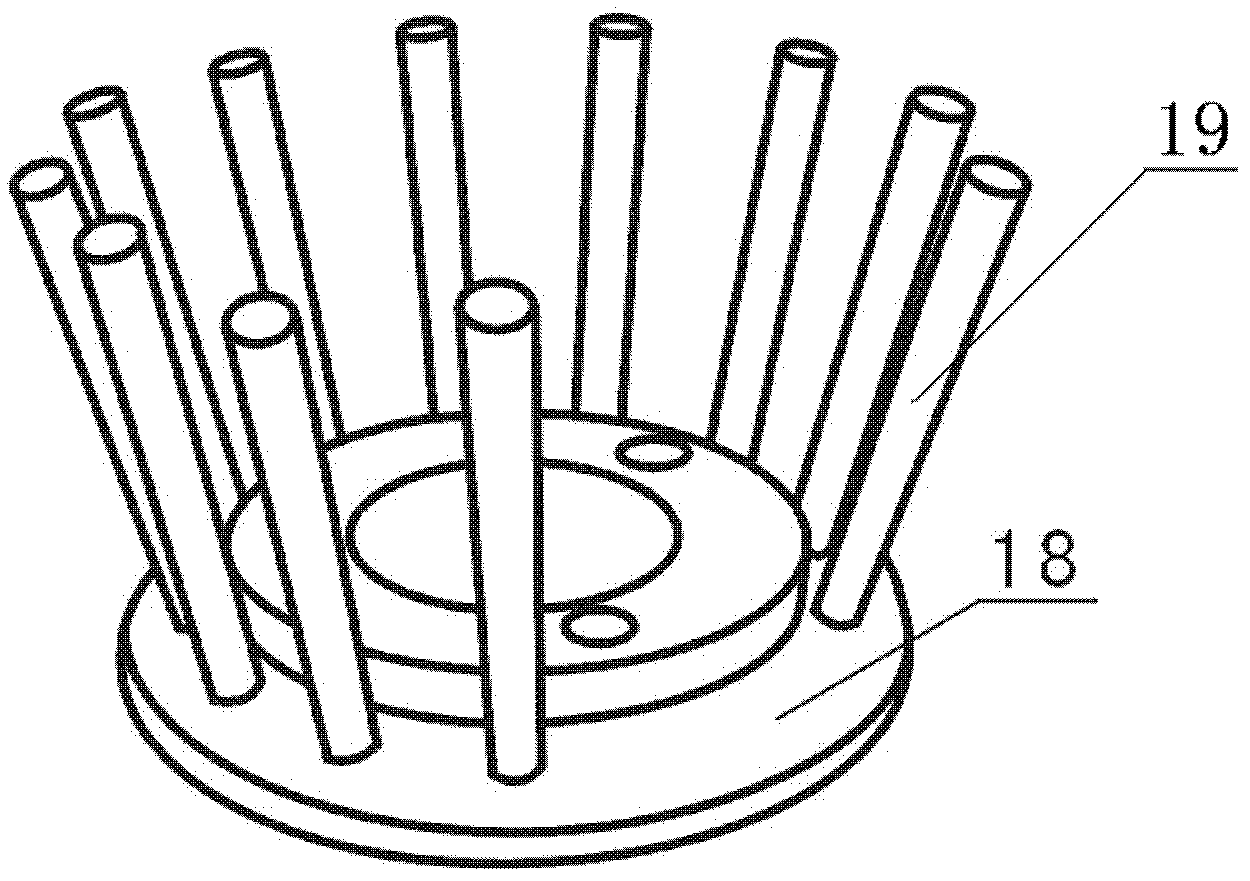

[0030] Embodiment: a kind of energy-saving electric pump (see figure 1 ), characterized in that it includes a base 1, a check valve 2, a suction port 3, a pump 4, a guide bearing seat 5, an inner oil suction cover 6, an outer oil suction cover 7, a motor 8, a flange body 9 and a joint 10; The base 1 has the inlet I A of the main channel and the inlet IIB of the bypass large flow channel; the inlet I A of the main channel corresponds to the inner space of the inner oil suction cover 6, and the inlet IIB of the bypass large channel corresponds to the inner oil suction cover 6. Between the cover 6 and the outer oil suction cover 7, an annular space is formed correspondingly; a suction inlet 3 is installed above the inlet 1 A of the main channel; a pump 4 is installed on the suction inlet 3; the above pump 4 is connected with the motor through the guide bearing seat 5 8 connection; the upper part of the motor 8 is connected to the joint 10 through the flange body 9; a check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com