Energy-saving environmental-friendly noise reduction system applied to hydraulic mechanism

A technology of energy saving, environmental protection and noise reduction system. It is applied in the fields of fluid pressure actuation system components, energy industry, mechanical equipment, etc. It can solve the problems of hydraulic component damage, affecting system quality, affecting service life, etc., so as to improve service life and reduce noise. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

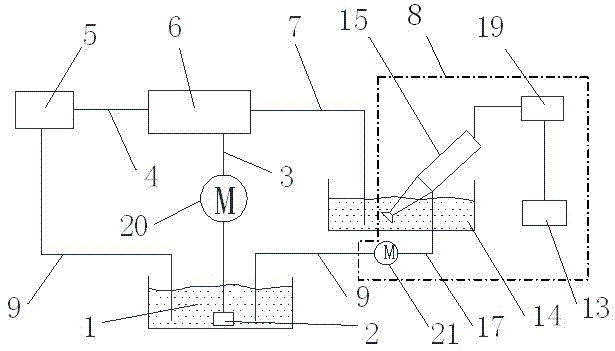

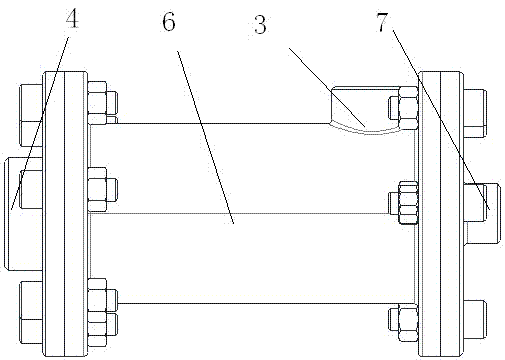

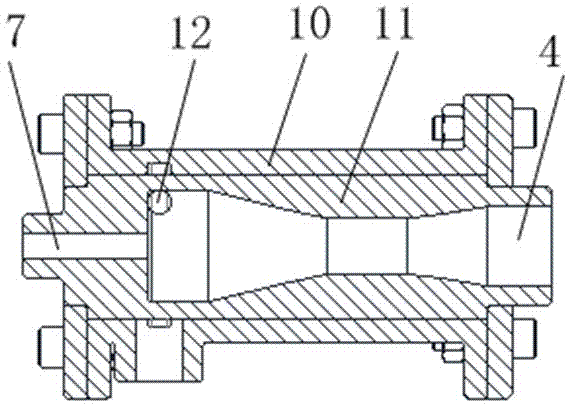

[0028] Such as figure 1 As shown, the present invention connects a primary degassing valve 6 between the hydraulic pump 20 and the actuator 5, and one outlet of the primary degassing valve 6 is connected to the actuator 5 through the hydraulic oil outlet pipeline 4, and the primary degassing valve 6 The other outlet of the gas-oil mixture outlet 7 is connected to the oil distribution tank 14; the hydraulic oil stored in the oil distribution tank 14 flows into the main oil tank 1 after being degassed by the secondary degassing system 8, and the primary degassing valve 6 is connected in series in the hydraulic mechanism ; The secondary degassing system 8 that runs alone is connected in parallel in the hydraulic mechanism.

[0029] Its working principle is: when the hydraulic mechanism is working, the hydraulic oil is driven by the hydraulic pressure 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com