Space-wedged-type pressurizing mechanism and combined-type friction transmission wheel with same

A technology of pressurizing mechanism and friction transmission, which is applied in the direction of transmission, gear transmission, and components with teeth, etc., and can solve problems such as fatigue pitting, strong axial joint force/compression force, wear and crushing, etc. , to achieve the effect of high working reliability, long life and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

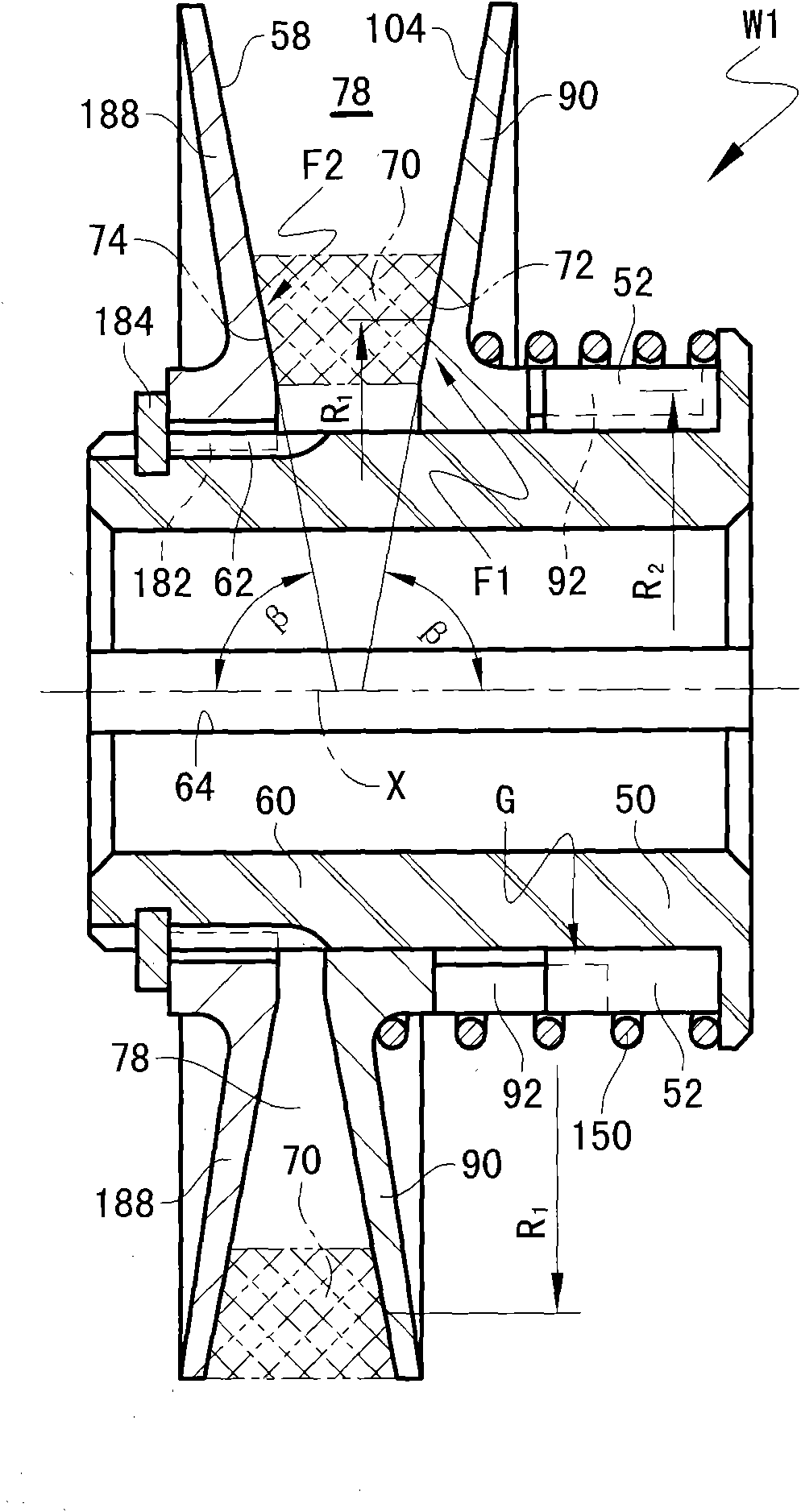

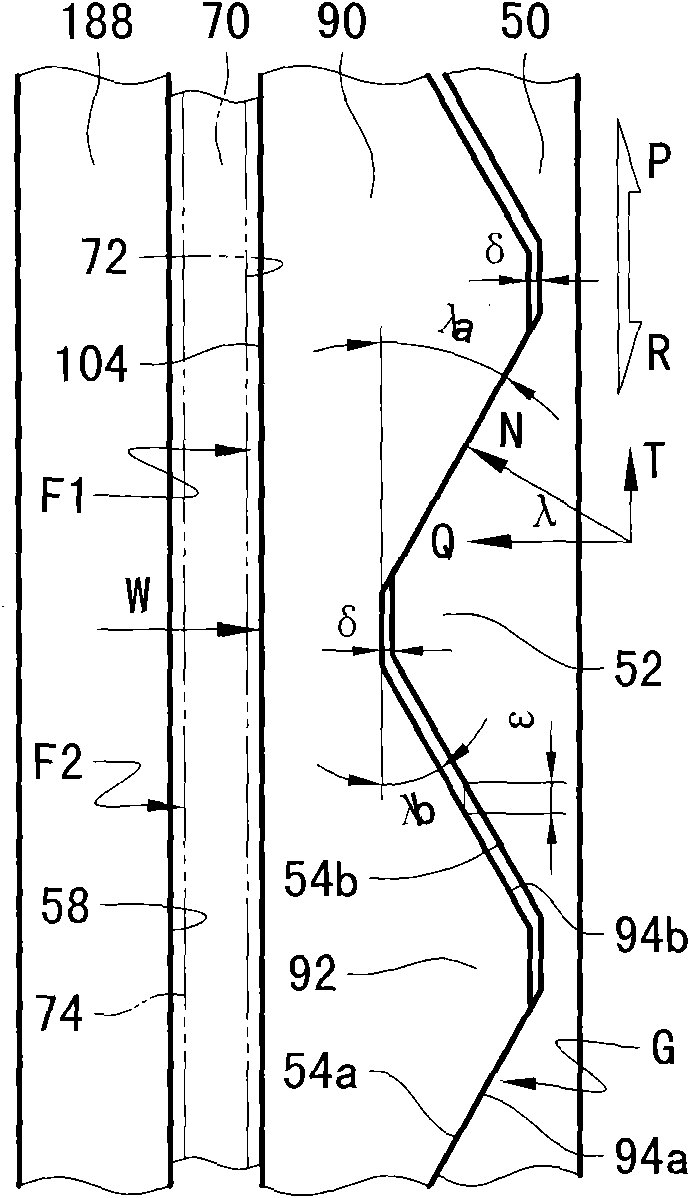

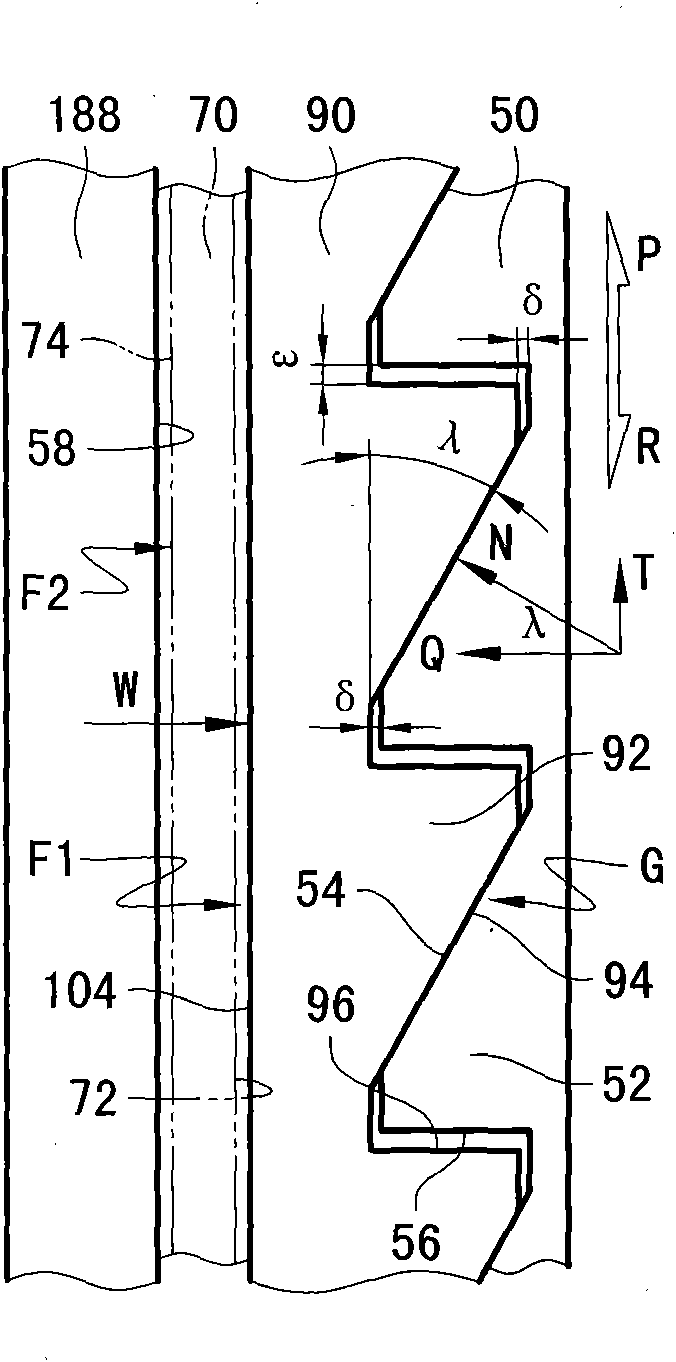

[0033] Embodiment 1: One-sided mobile combined friction transmission wheel W1

[0034] see figure 1 , Figure 2A-2B , the drive wheel W1 comprises a guide 50 formed around the axis X, preferably in the shape of a stepped ring. On the inner end surface of the outer ring side, a group of helical guide teeth 52 optimally uniformly distributed around the axis X is arranged, and on the outer peripheral surface of the middle part of the tubular base body 60 used as the transmission shaft extending from the inner ring side toward the inner end, it can be The preferably ring-shaped intermediate part 90 is radially positioned slidingly. The intermediary member 90 is permanently fitted with the guide member 50 through a group of helical guide teeth 92 that are complementary to the guide teeth 52 on the end surface of the tubular section facing the guide member 50, so as to form a surface contact The rotation guiding mechanism G is the core part of the space wedging type pressurizing ...

Embodiment 2

[0056] Embodiment 2: One-side mobile combined friction transmission wheel W4 with adjustable speed ratio

[0057] Such as Figure 5 As shown, as a modification to the transmission wheel W1, the guide member 50 itself becomes a solid transmission shaft in the shape of a stepped shaft, and since the rotation guide mechanism G is set as a peripheral spiral type that can only be pressurized in one direction, the transmission wheel W4 is therefore It will only be possible to transmit torque in one direction. Correspondingly, the guide member 50 may be directly provided with a limiting flange 68 for forming an axial force closed interference connection. In order to actively change the transmission speed ratio, the transmission wheel W4 also includes an adjustment mechanism D. The mechanism D includes an external helical tooth 138 arranged on the outer peripheral surface of the tubular base of the intermediary member 90, and an internal helical tooth 136 provided on the outer side ...

Embodiment 4

[0060] Embodiment 4: Gear transmission type combined friction transmission wheel W5 with adjustable speed ratio

[0061] Such as Image 6 As shown, compared with the transmission wheel W4, the difference of the transmission wheel W5 is only that the adjustment mechanisms Da and Db for changing the transmission speed ratio are set as two gear mechanisms. Wherein, on the outer peripheral surface of the reference section 51 of the guide member 50, a control force output gear ring 130 is fixedly connected via, for example, a flat key 134 and a snap ring 184a, and gear teeth 132 are arranged on the outer peripheral surface thereof. The double gear ring 140 is circumferentially connected to the outer peripheral surface of the tubular base of the intermediary member 90 through a spline pair, and two sets of double gear teeth 144 and 146 are respectively arranged on the outer end / right end of the outer peripheral surface. The first duplex gear 190 is rotatably fixed to the first gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com