Energy-saving self-control oil burning system

A combustion system and fuel oil technology, applied in the direction of using various fuel combustion, controlled combustion, gas fuel burners, etc., can solve the problems of insufficient fuel combustion, unfavorable energy saving and emission reduction, inconvenient use, etc., and achieve good atomization effect , improve fuel combustion conditions, improve the effect of learning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

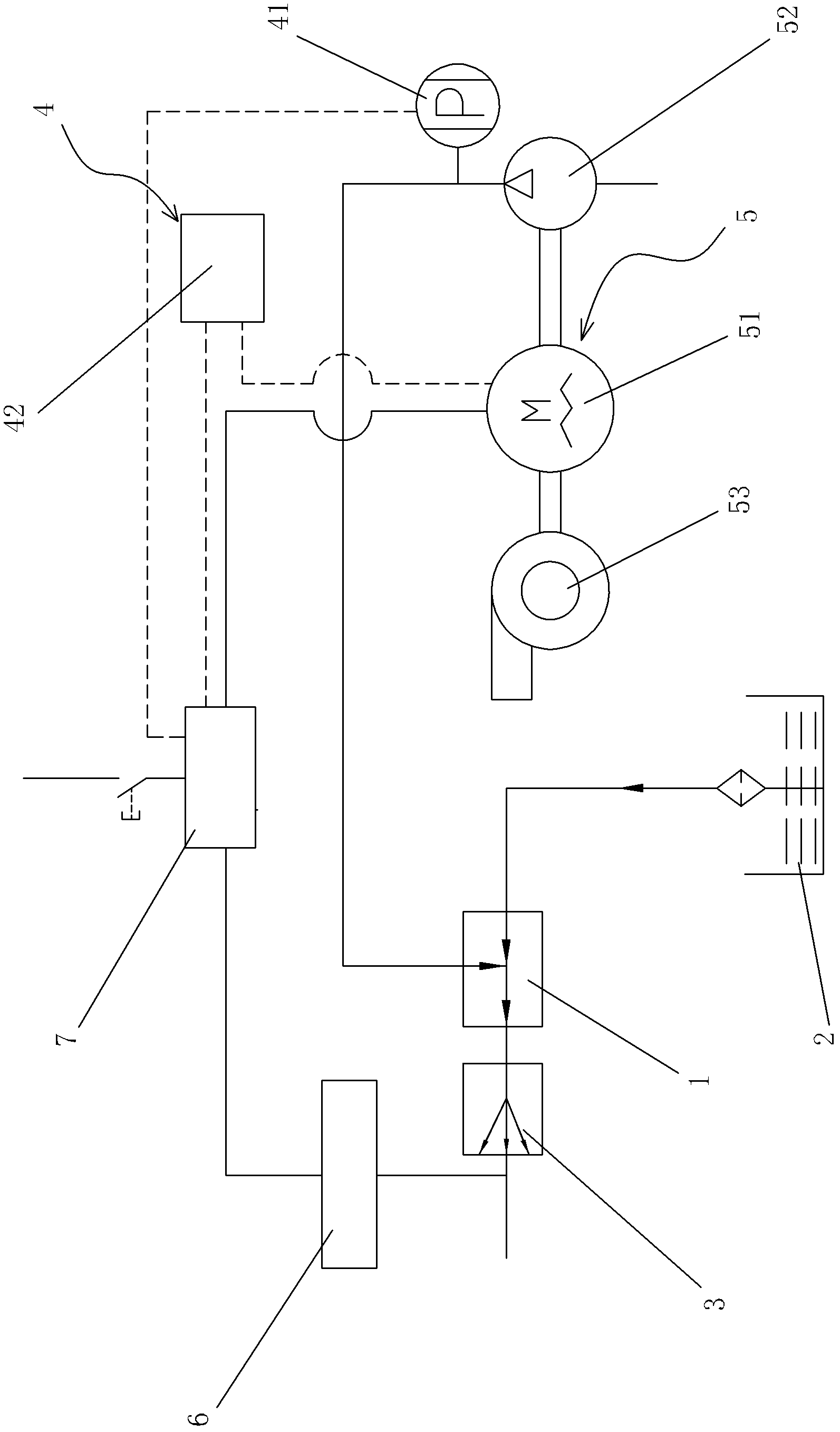

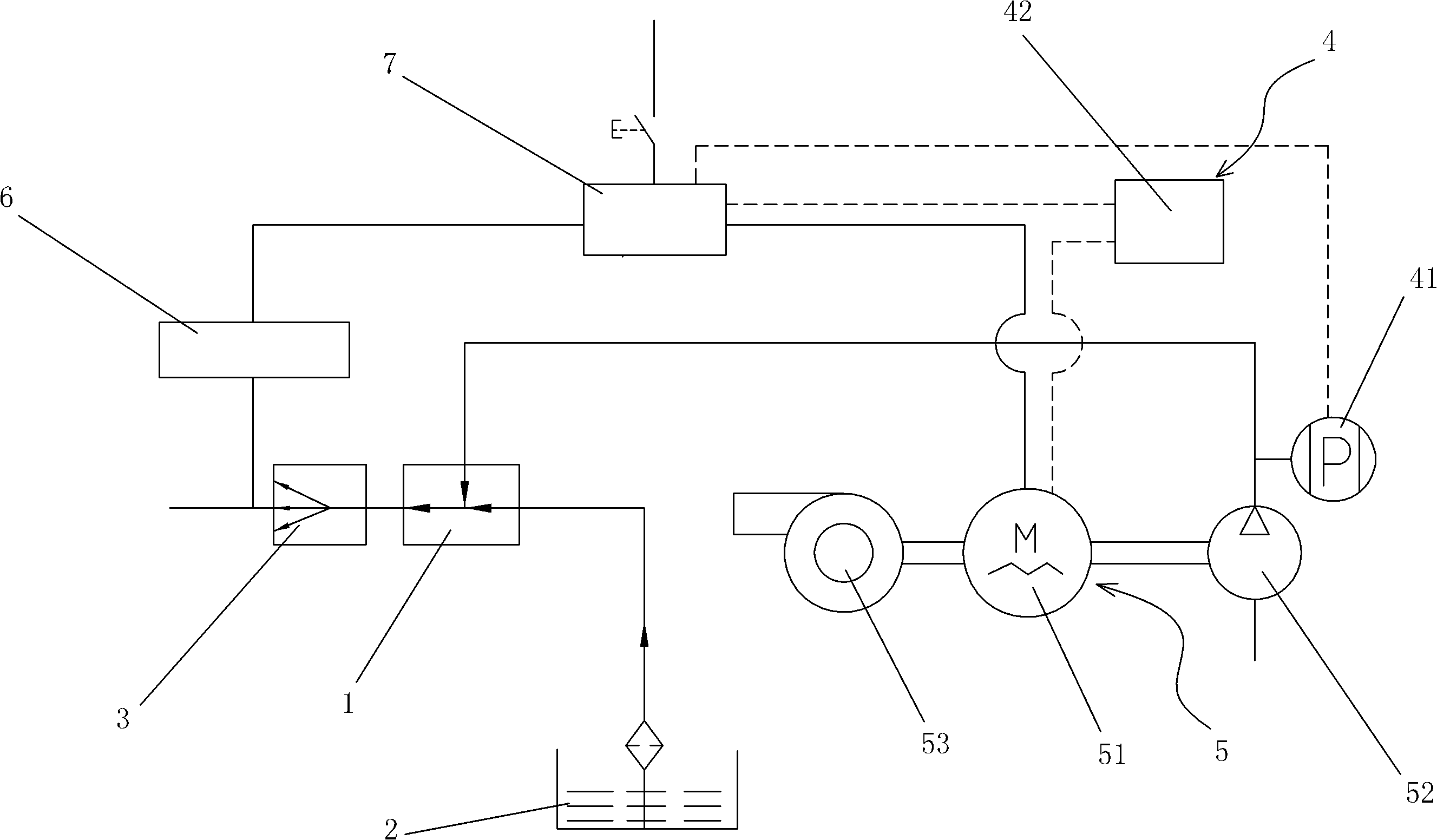

[0015] Such as figure 1 An energy-saving self-controlled fuel combustion system is shown, comprising a manifold three-way valve 1, on which the manifold three-way valve 1 is respectively connected with a fuel tank 2, an air atomizing fuel nozzle 3 and a fuel tank 2 The fuel in the air atomization fuel nozzle 3 is delivered to the compressed air mechanism 5 that fully mixes the fuel and air. An automatic ignition device 6 is provided on one end of the air atomization fuel nozzle 3. The automatic ignition The device 6 is connected with the main controller 7, and the automatic control assembly 4 that can check and adjust the work of the compressed air mechanism 5 is provided on the compressed air mechanism 5, and the automatic control assembly 4 and the main controller 7 phase connections.

[0016] The compressed air mechanism 5 described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com