Drying device

A drying device and drying technology, which can be applied in the directions of drying gas arrangement, drying chamber/container, non-progressive dryer, etc., can solve the problems of long cylinder and bulky device as a whole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

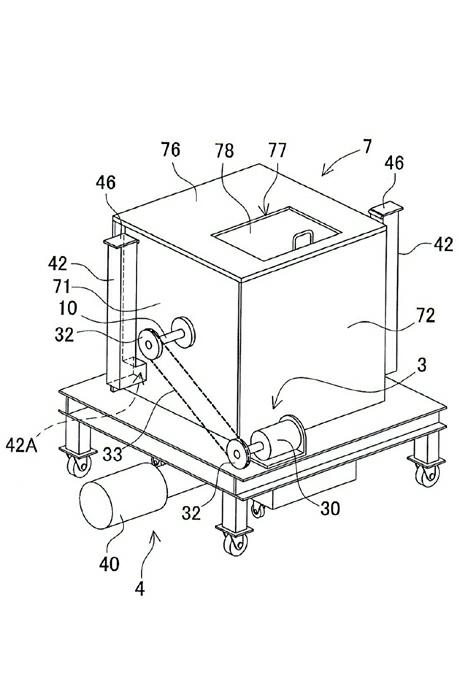

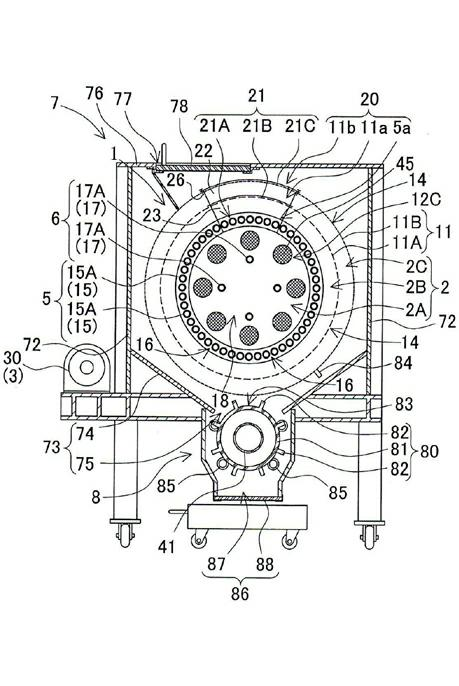

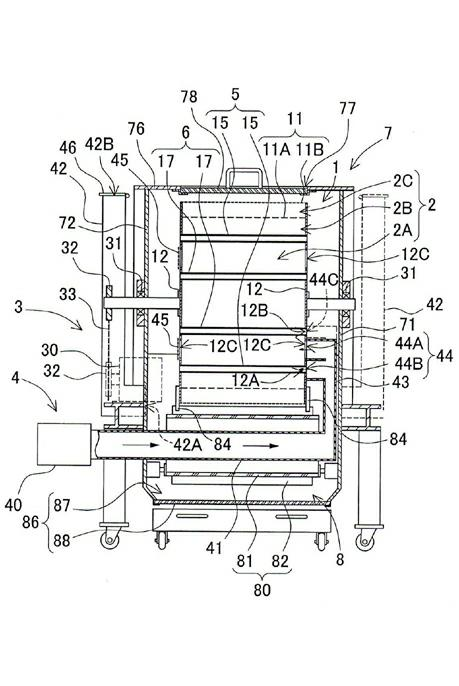

[0029] The embodiment of the present invention will be described according to the figures below. However, the embodiments shown below are for the purpose of embodying the technical idea of the present invention, and the drying device is illustrated, and the present invention does not specify the following drying device in particular. In addition, in order to make the claims easier to understand, this specification attaches numbers corresponding to the parts shown in the embodiments to the parts shown in the claims and the summary of the invention. However, the parts shown in the claims are by no means the parts that specify the embodiment.

[0030] The drying device of the present invention can be used, for example, to dry the dehydrated filter cake obtained by dehydrating the waste liquid of an electroplating factory with a filter press to a powder of a predetermined particle size. Since the dehydrated filter cake contains as much as 70% to 90% (weight ratio) of water, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com