Optical-fiber curing method of frameless optical induction ring of optical-fiber gyroscope

A fiber optic gyroscope and curing method technology, applied in Sagnac effect gyroscopes and other directions, can solve the problems of fiber optic gyroscope drift, fiber breakage, skeleton deformation, etc., and achieve the effects of strong operability, cost reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] like Figure 6 , the implementation steps of the present invention are as follows:

[0033] (1) Step 1:

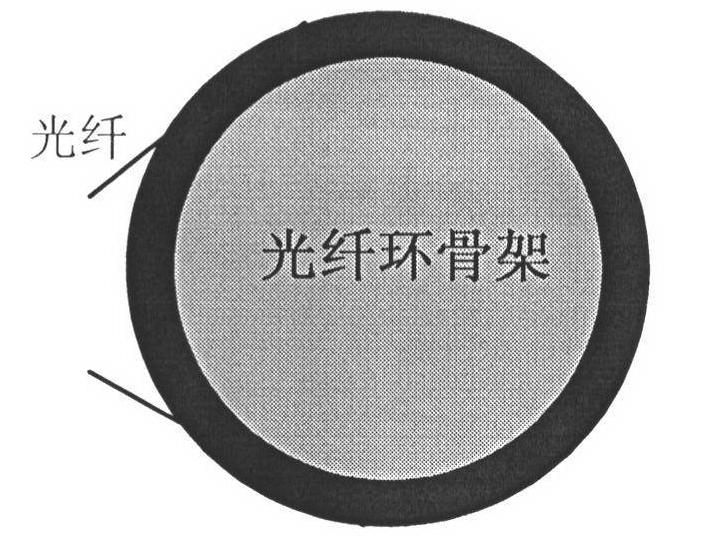

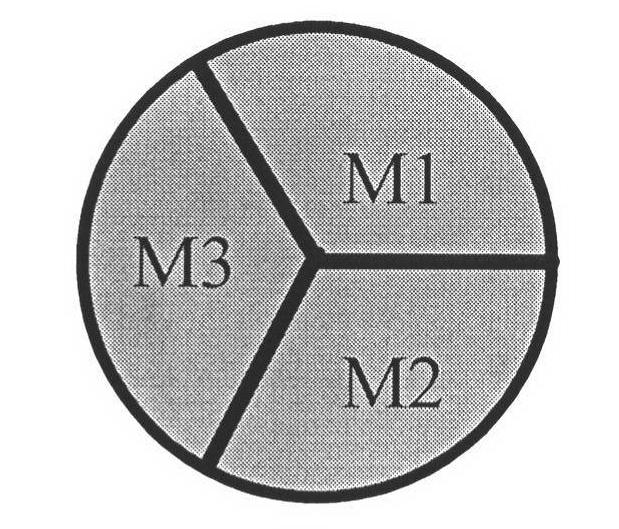

[0034] according to image 3 In this way, the cylindrical inner frame around which the optical fiber ring is wound is axially divided into three equal parts, and divided into three modules: M1, M2, M3, and there is a gap of 1.5mm to 2.5mm between adjacent modules;

[0035] (2) Step 2:

[0036] The baffles on both sides of the frame around which the optical fiber ring is wound are respectively in accordance with Figure 4 , Figure 5 Equally divided into three lobes, one side is A, B, and C, and the other side is D, E, and F. There is a gap of 0.5mm to 1.0mm between adjacent lobes. The orthographic projections of the D lobe and F lobe overlap, the B lobe overlaps the orthographic projections of the D lobe and E lobe on the opposite side, and the C lobe overlaps the orthographic projections of the E and F lobes on the opposite side;

[0037] (3) Step 3:

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com