Dynamic balance assembly testing device of engine rotors

A technology of rotor dynamic balance and test device, which is applied in static/dynamic balance test, measurement device, machine/structural component test, etc., can solve the problems of difficult assembly, low efficiency, complicated equipment operation, etc., and achieve high economic value and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

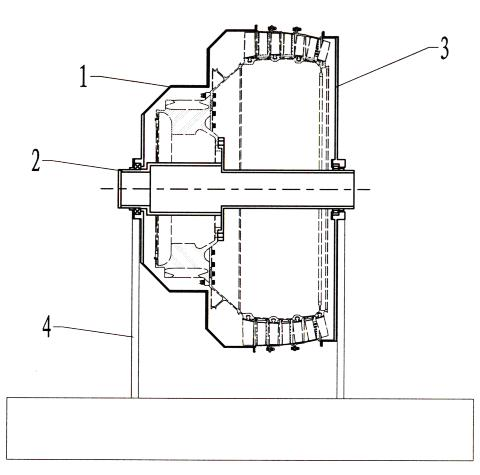

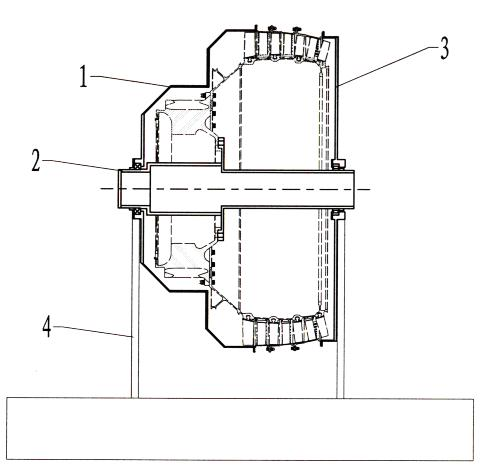

[0020] This embodiment provides a dynamic balance test device for an engine rotor. The balance test device includes a front balance process casing 1, a balance mandrel 2, a rear balance process casing 3, and a balance machine 4;

[0021] Among them: the front balance process casing 1 is connected to the front stator of the rotor with the stator of the engine, the rear balance process casing 3 is connected to the rear casing of the rotor with the engine stator; the front balance process casing 1 and the rear balance process casing 3 They are respectively installed at the front and rear ends of the balance mandrel 2. The rotor with the stator of the engine is respectively connected with the front balance process case 1 and the rear balance process case 3 through the stator, and finally forms a balance unit body with the balance mandrel 2, and relies on the balance mandrel 2 Supported on a balancing machine.

[0022] The structure of the front balance process casing 1 is a steppe...

Embodiment 2

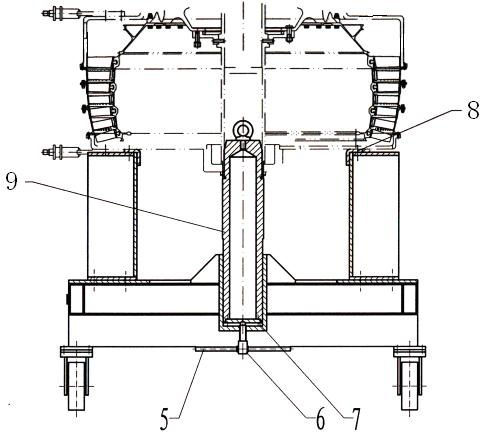

[0027] This embodiment provides an engine rotor dynamic balance assembly and transportation device, the device includes a trigger rod 5, a push rod 6, a baffle plate 7, a support block 8, and a column 9;

[0028] Among them: the lever 5 and the ejector rod 6 are fixedly installed, and have the function of adjusting the vertical position of the ejector rod 6, the baffle plate 7 is located at the top of the ejector rod 6, the column 9 can move the vertical position according to the adjustment of the ejector rod 6, and the balance mandrel 2 In contact with the column 9, the support block 8 is located between the engine stator casing and the assembly vehicle, and the column 9 is located between the engine rotor and the assembly vehicle.

[0029] The assembly vehicle is provided with a multi-functional supporting block 8 and a multi-functional ejector rod 6 for adjusting the vertical movement of the assembly unit body, and is convenient for transportation in the final state.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com