Method for determining magnesium or magnesium alloy corrosion rate and special experimental device

A corrosion rate, magnesium alloy technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of low sensitivity, increase the experimental workload, and influence the reliability of experimental results, and achieve a simple structure of the experimental device. , The calculation results are reliable and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

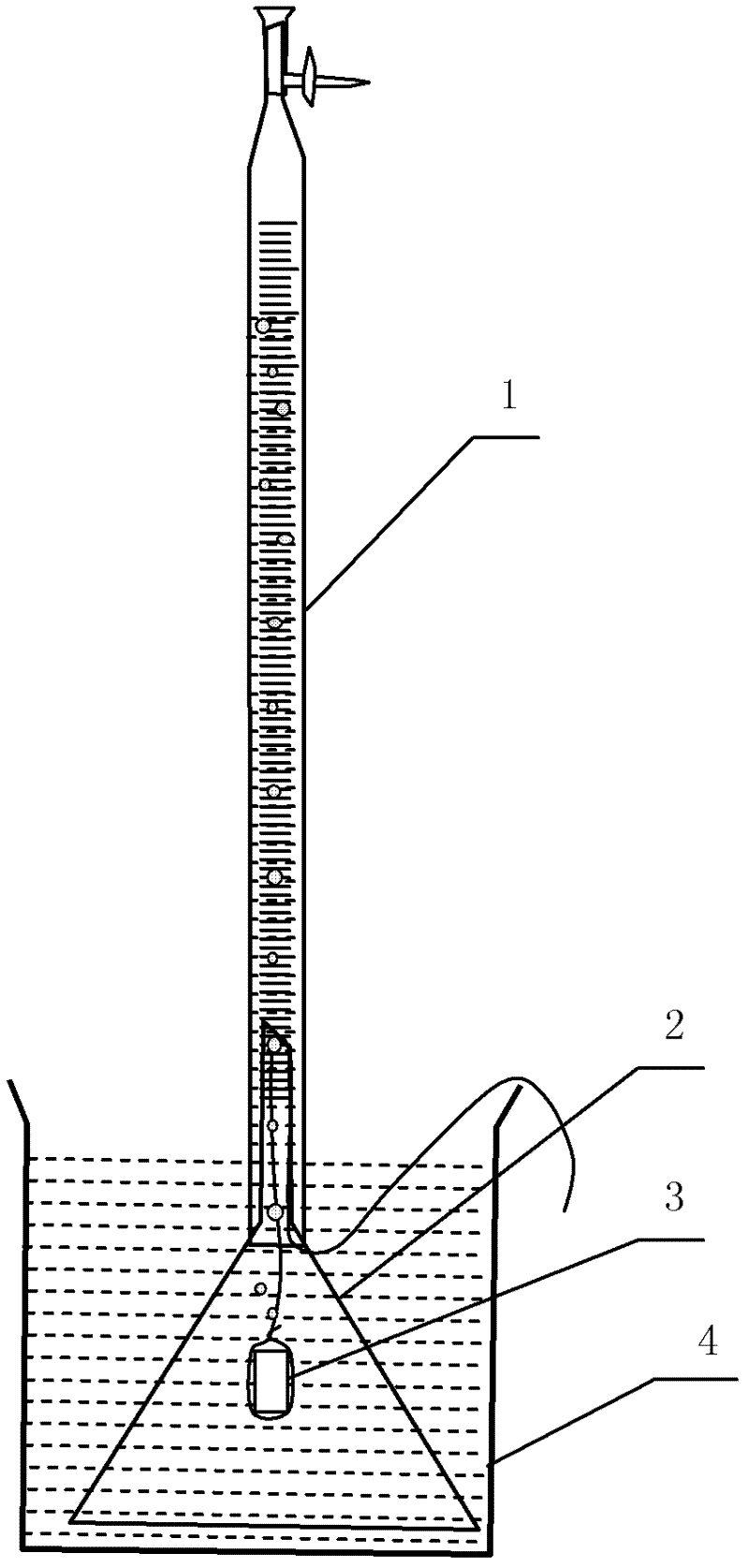

[0034] Put the funnel upside down in a container filled with 3.5% NaCl solution, hang the cast high-purity magnesium inside the funnel with a fishing line, and turn upside down a burette at the end of the funnel, the mouth of the burette is lower than the liquid level of the corrosive solution in the beaker. Vacuum the inside of the burette with an aspirator, and suck the solution to the highest mark of the burette. The hydrogen gas generated by the corrosion of the sample enters the space above the liquid level of the burette from the funnel in the form of bubbles, and the hydrogen will replace the burette in the burette. Part of the solution causes the liquid level in the burette to drop.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com