Peeling test method and device for white layer tissues of rolling bearing

A rolling bearing and test method technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of poor consistency, repeatability and reliability of test data, short time for white layer structure formation and peeling, and white layer tissue peeling time. Long and other problems, to achieve the effect of simple structure, high data consistency, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

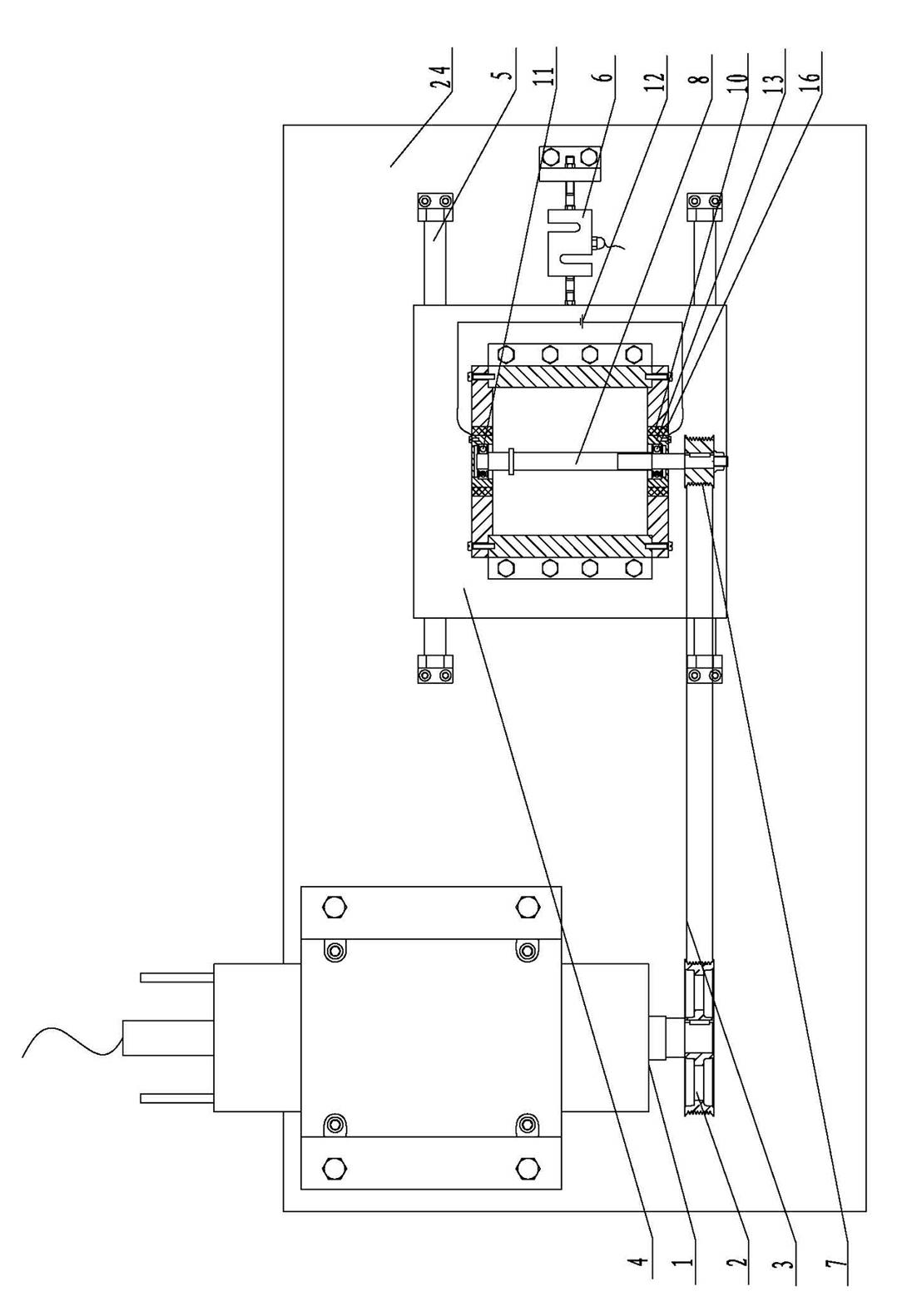

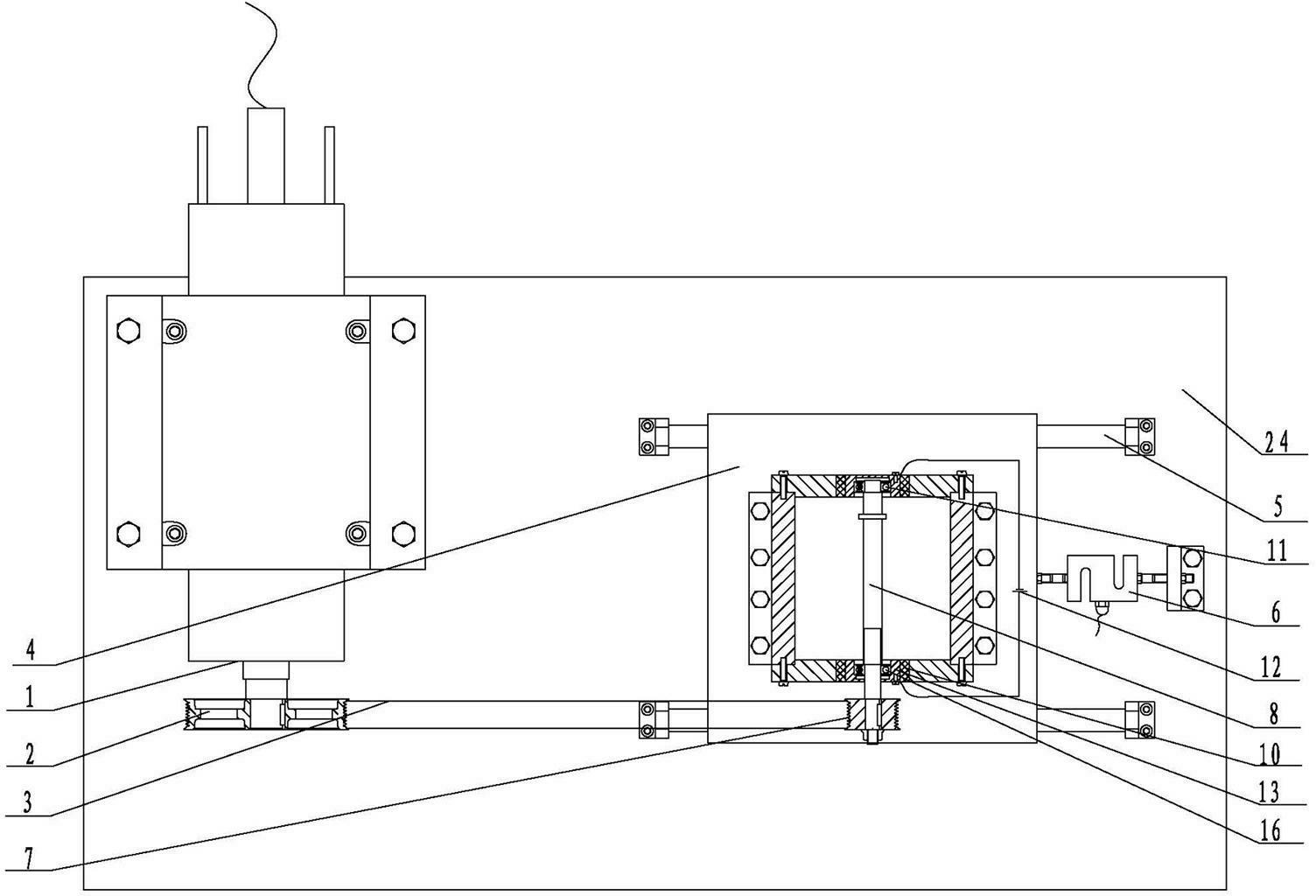

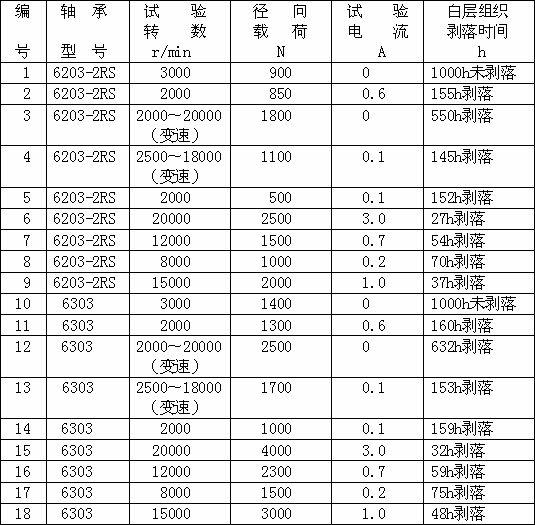

[0024] The drive motor 1 of the illustrated embodiment is a high-speed, AC variable-frequency speed-regulating motor with a speed up to 9000 r / min, and its speed is regulated by a frequency converter, which can realize stepless speed regulation and meet different test conditions and requirements. The drive motor 1 The current is displayed by the frequency converter, and the control system displays the number of revolutions of the test rolling bearing 16. The driving motor 1 is fixed on the base 24 . Large drive belt pulley 2 is installed on the drive motor output shaft, and its specification size is suitable with the specification size of automobile engine drive belt pulley. The auxiliary support bearing 11 is installed at the rear end of the metal installation shaft 8 with good electrical conductivity, the test rolling bearing 16 is installed at the front of the installation shaft 8, and the front end of the installation shaft 8 is installed with a small installation shaft pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com