Optical lens with antistatic coating

An optical lens and antistatic technology, applied in optics, coatings, optical components, etc., can solve the problems of anti-reflection coating mechanical and optical performance damage, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

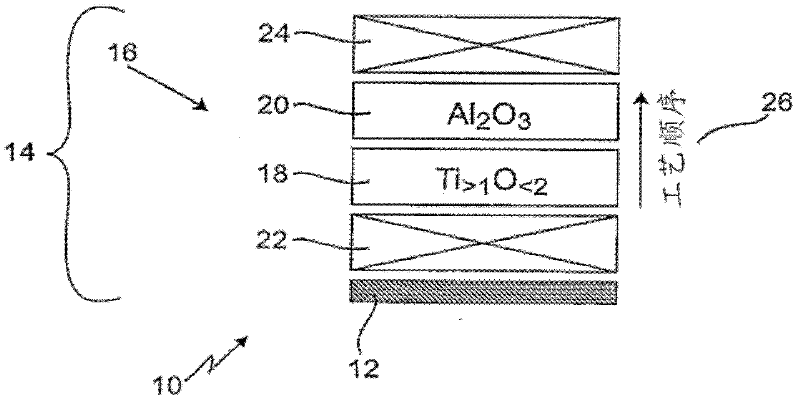

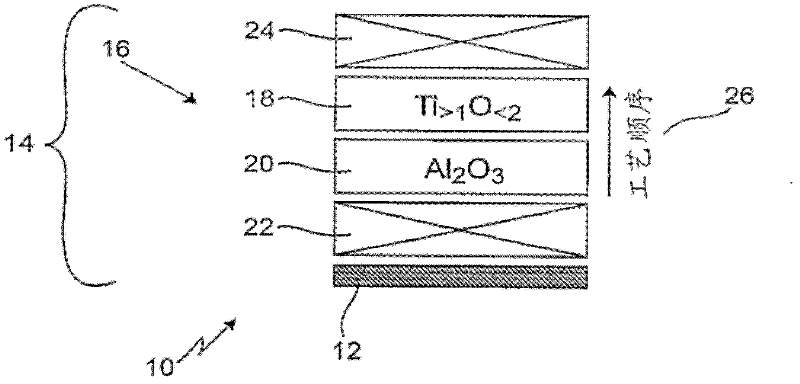

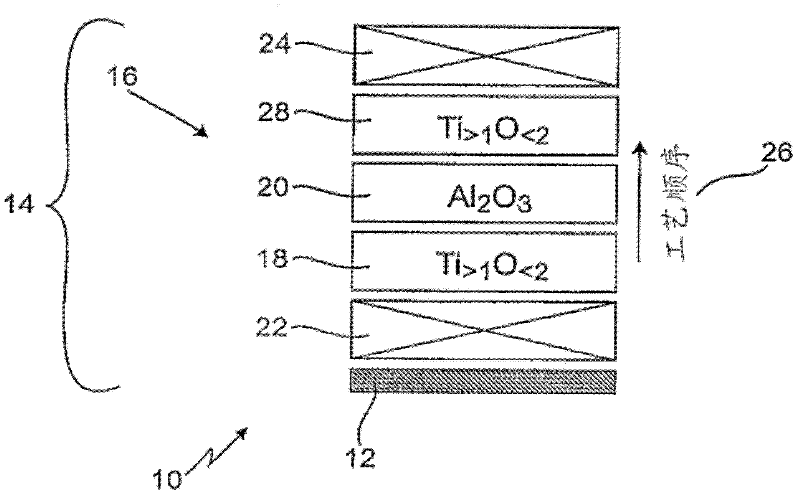

[0039] figure 1 Optical lens 10 in one embodiment is shown. The optical lens 10 has a lens element 12 provided with a coating 14 . The coating 14 includes a plurality of layers 16 that are subsequently applied.

[0040] In particular, the coating 14 includes a first layer 18 made of titanium oxide (TiO 2 ) are formed in a substoichiometric ratio. Here, the term "substoichiometric" refers to the fact that oxygen deficiency dominates; this composition thus leads to Ti >1 o <2 . Made of alumina (Al 2 o 3 ) fabricated second layer 20 is disposed thereon. The substoichiometric first layer 18 and this second layer 20 together form an electrically conductive boundary layer which integrates an antistatic effect in said optical lens 10 in view of its electrical conductivity.

[0041] The arrangement of the first layer 18 and the second layer 20 within the coating 14 does not have to be at the surface of the coating 14 . Illustratively, an underlayer 22 may be provided between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com