Volume modeling method for coal bed underground combustion space areas

A modeling method and technology of fuel-air zone, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as affecting the temperature field distribution of rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

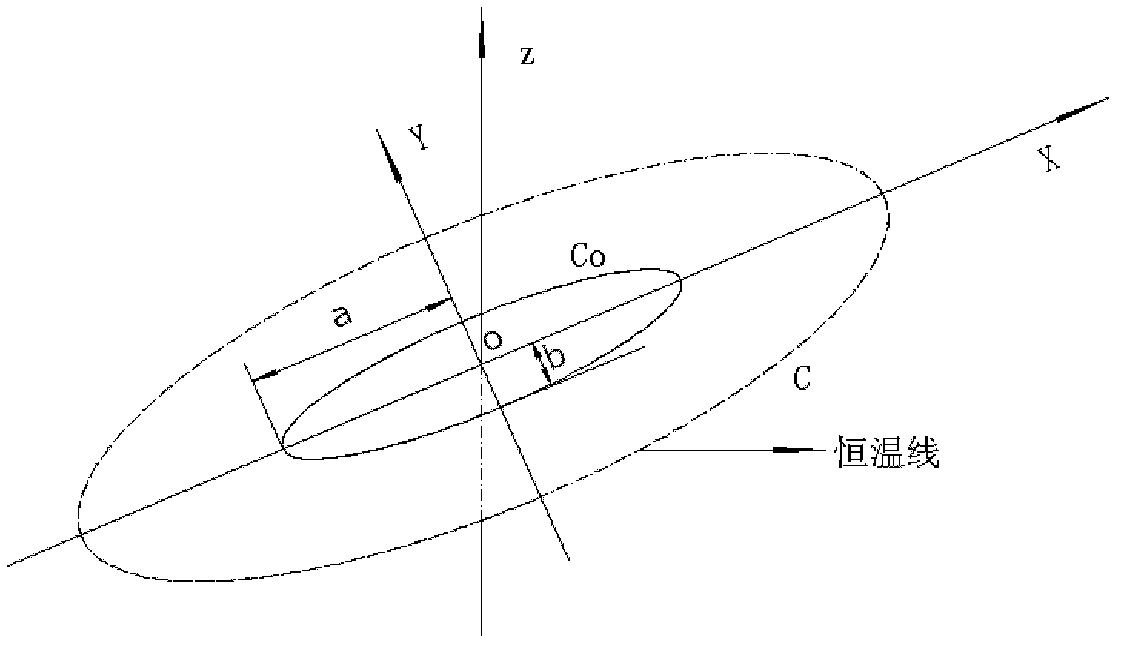

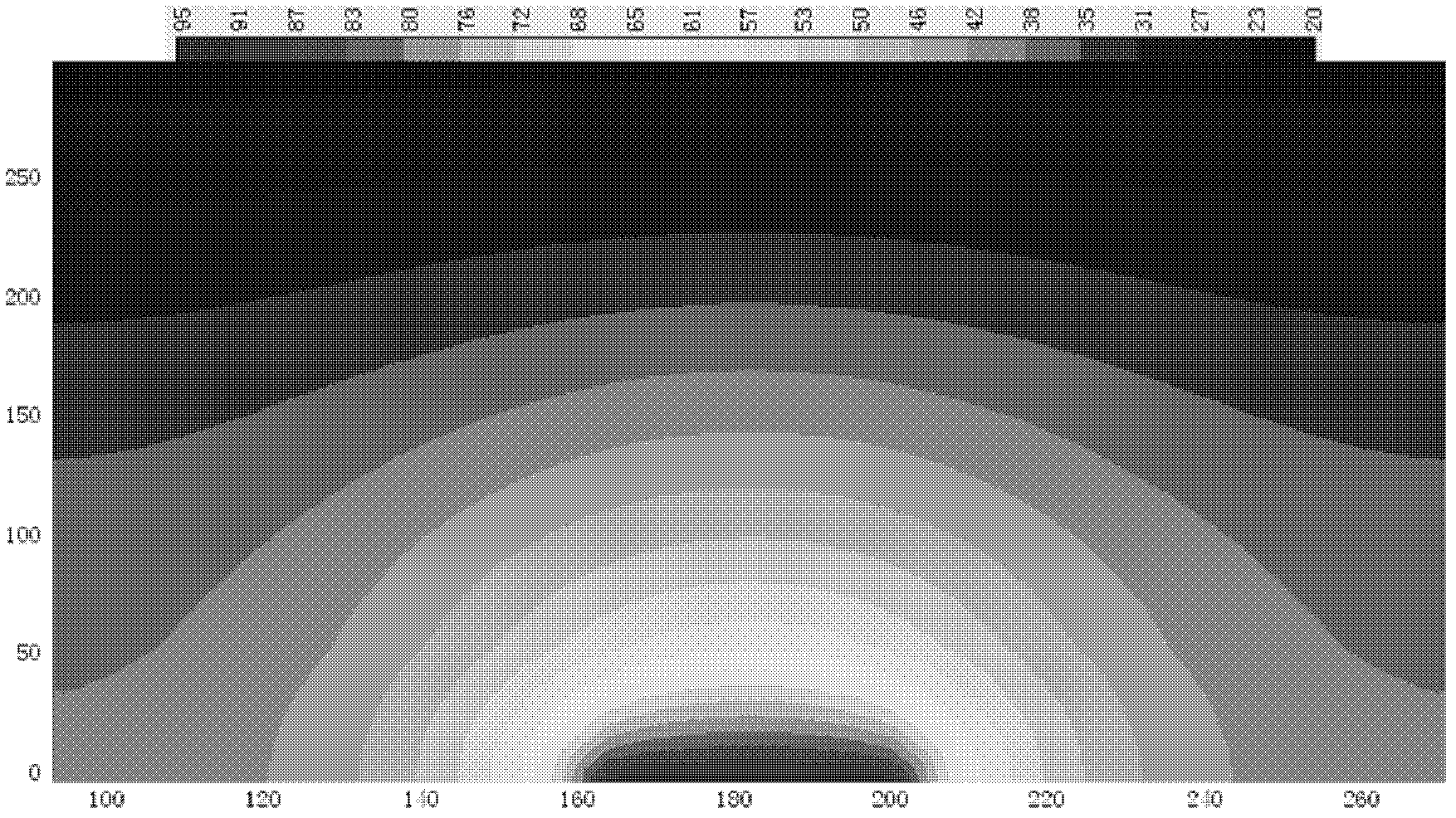

[0038] Such as Figure 7 As shown, the present invention provides a volumetric modeling method for underground coal seam burn-up zones, comprising the following steps:

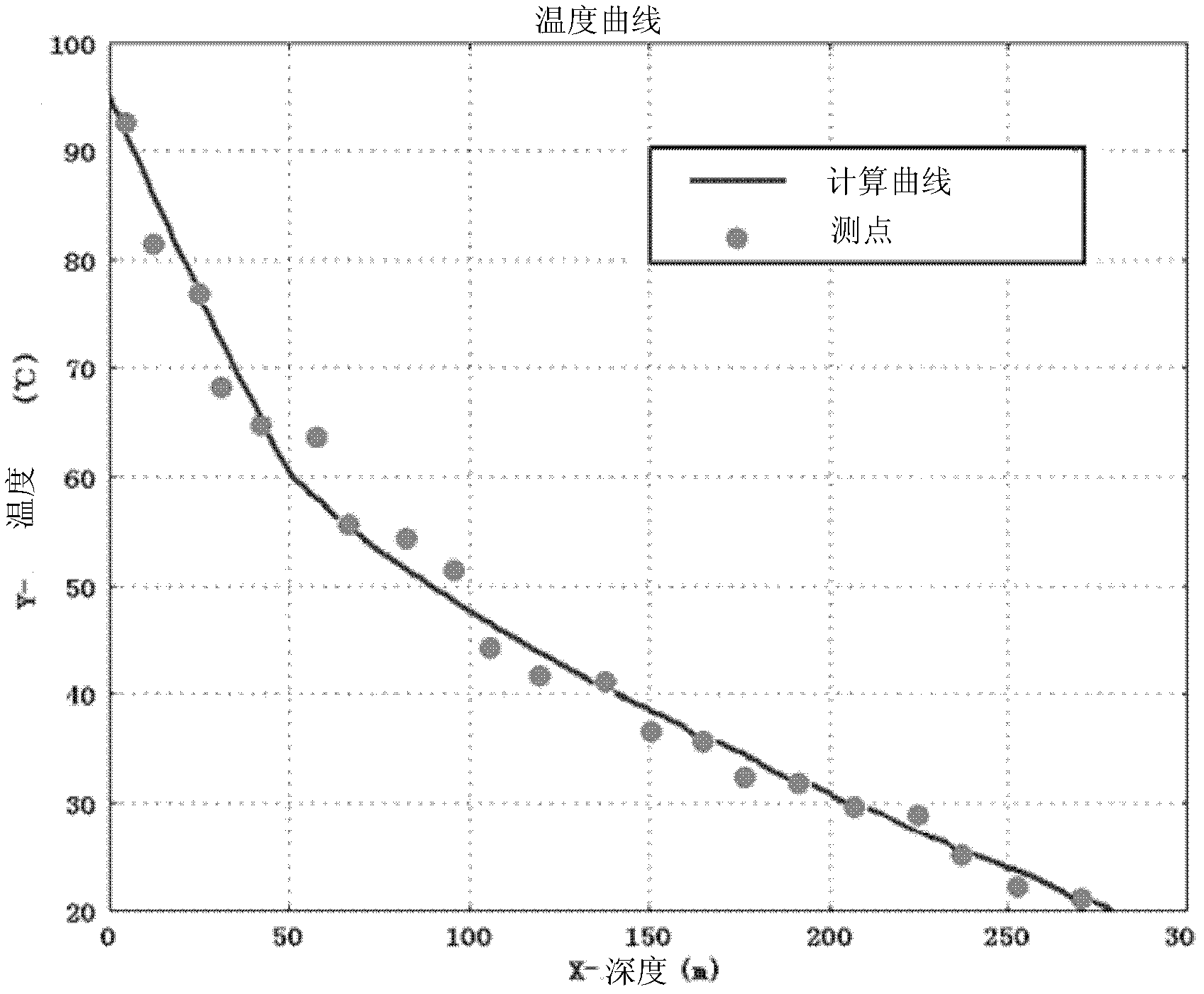

[0039] (1) According to the heat balance principle of the unit body inside the rock mass, the one-dimensional unsteady temperature field equation under the action of seepage is established in the rock formation plane:

[0040] cρ ∂ T ∂ t = - c w ρ w ∂ ( v ) T ∂ x + ∂ ∂ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com