Protection assembly of movable static contact of plastic shell breaker

A technology of molded case circuit breaker and dynamic and static contacts, applied in circuit breaker parts, circuit breaker contacts, etc., can solve the problems of static contacts failing to protect, affecting switch performance, and reducing electrical clearance, etc. Compact structure, smooth movement, and the effect of preventing the adhesion of metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

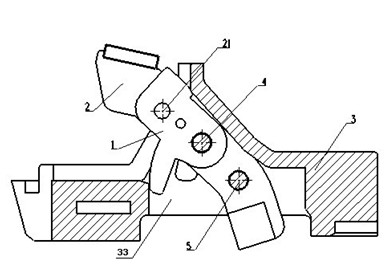

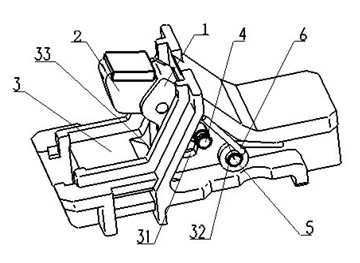

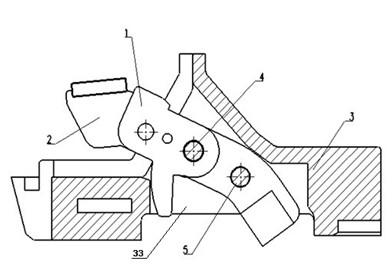

[0017] see Figure 1-3 The protection assembly of the movable and static contacts of the molded case circuit breaker of the present invention is composed of a static contact plastic part 1 and a plastic support part 3, the static contact plastic part 1 is wrapped outside the static contact 2, and the plastic support part 3 has a container in the middle The cavity 33 , part of the static contact plastic part 1 and part of the static contact 2 are located in the cavity 33 . The first shaft 4 passes through the cavity 33 and the holes on the static contact plastic part 1 and the static contact 2 in the front and rear direction at the same time, and the two ends of the first shaft 4 are located in the corresponding third passages on the front and rear walls of the plastic support 3. In the slot 31 , the first shaft 4 can move along the corresponding third through slot 31 of the plastic support 3 . The static contact rotating shaft 5 also passes through the cavity 33 and the holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com