Novel nickel-hydrogen battery diaphragm

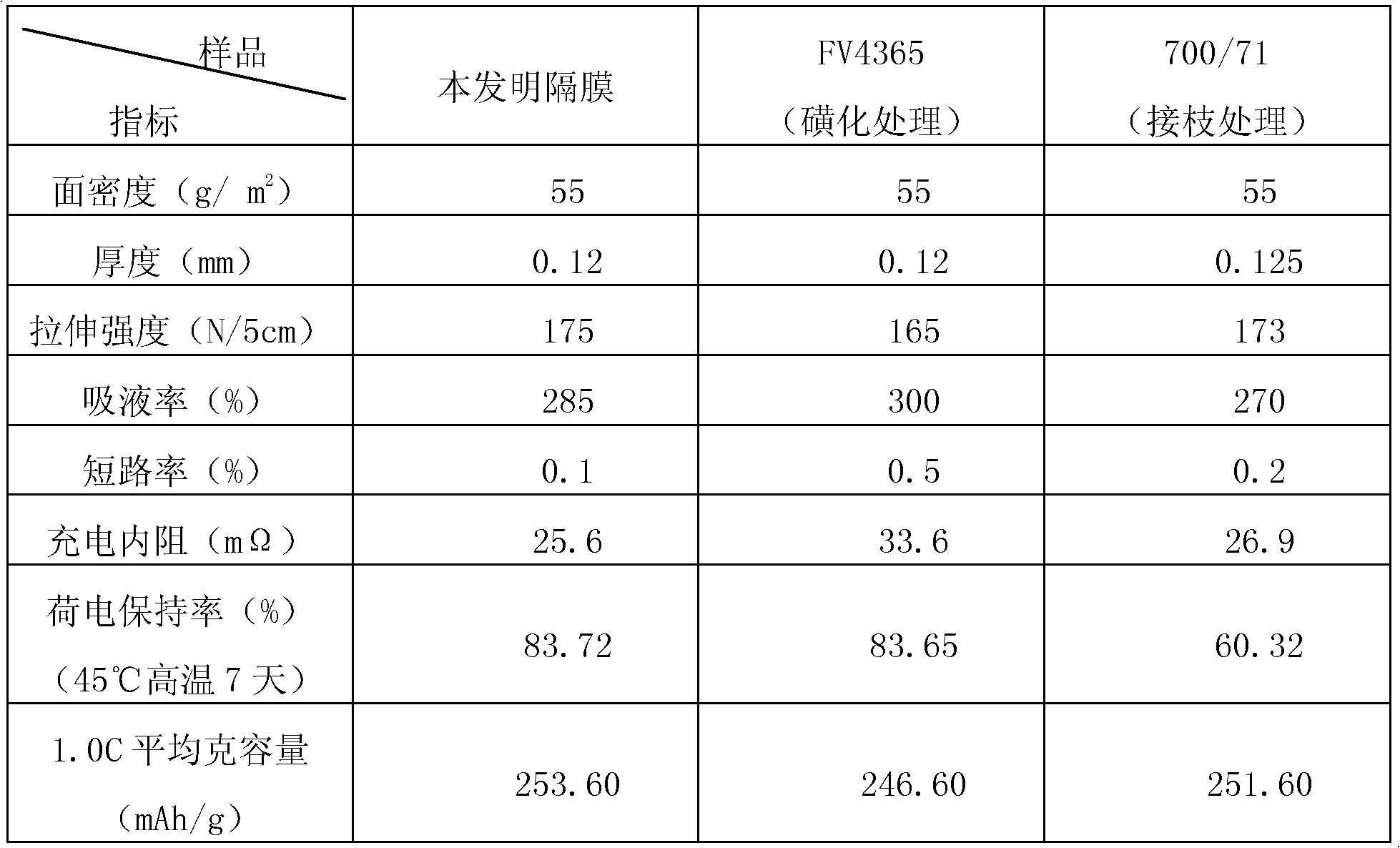

A nickel-metal hydride battery and diaphragm technology, which is applied in the field of battery diaphragms, can solve the problems of being unsuitable for the manufacture of nickel-hydrogen power batteries, easy carbonization of ultra-fine fibers, and low charge retention rate, and achieves excellent charge retention. Effect of homogenizing pore size and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

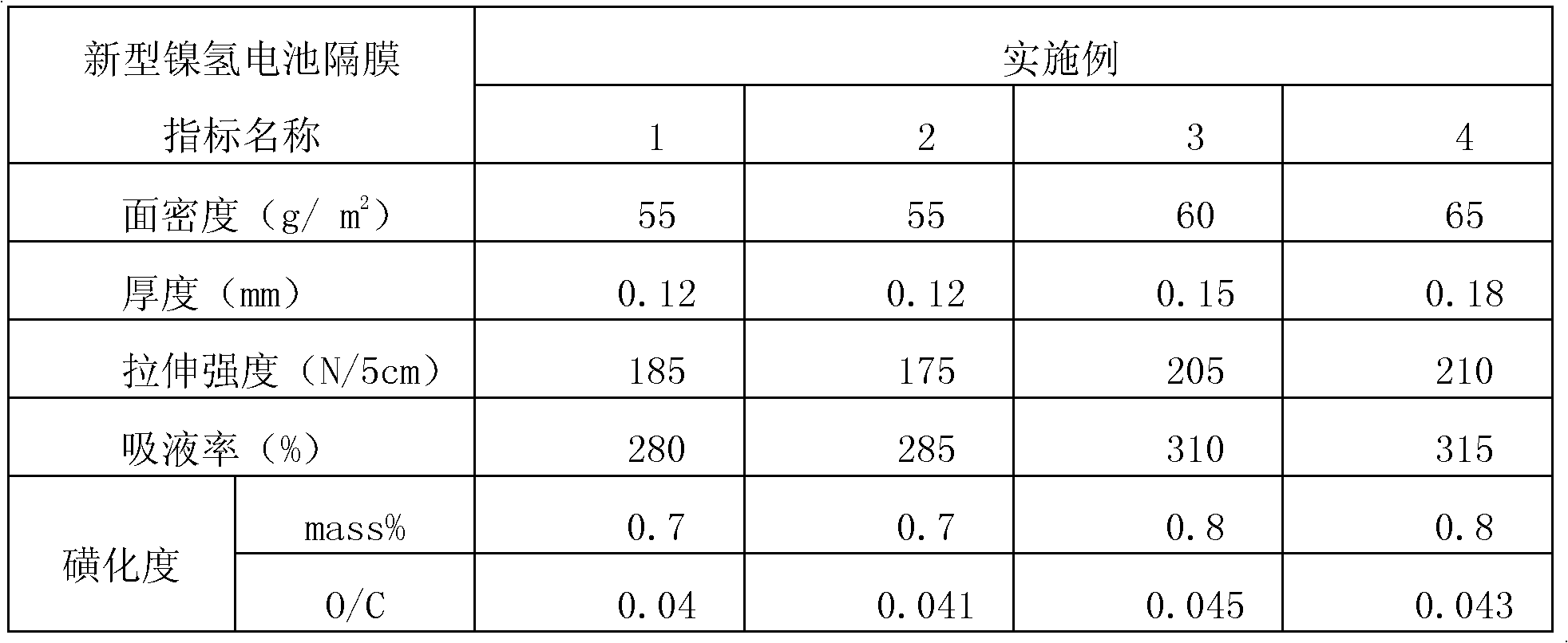

Embodiment 1

[0021] The fiber materials are batched according to the weight ratio, namely polyolefin sheath-core fiber, fiber fineness 0.8dtex, length 38mm, content 70%; polypropylene fiber, fineness 1.1dtex, length 38mm, content 25%; polypropylene fiber, fineness 0.3 dtex, length 38mm, content of 5%, the above fibers are formed by dry carding process, spunlace reinforced, dried in hot air at 120 ℃, adjusted to a certain thickness with a rolling mill, and made into diaphragm base cloth, diaphragm base cloth. Area density is 50g / m 2 .

[0022] The diaphragm base cloth is sent to the sulfonation reactor, and the sulfonation treatment is carried out with gaseous sulfur trioxide with a concentration of 95%. The sulfonated base cloth is sent to the alkali washing tank for neutralization reaction. The concentration of potassium hydroxide is 2% The alkali washing speed was controlled at 15 m / min, and then rinsed with deionized water, pressed, and dried.

[0023] Put the sulfonated diaphragm bas...

Embodiment 2

[0026] Using polyolefin skin-core fiber to make diaphragm base fabric, fiber fineness is 0.8dtex, fiber length is 2mm~15mm, using wet papermaking process, through beating, sizing, molding, hydroentanglement, drying, adjust the thickness of the base fabric , made of diaphragm base cloth, with an areal density of 50g / m 2 , and then processed according to the sulfonation and chemical grafting treatment methods and order of Example 1, to obtain an areal density of 55g / m 2 , a new type of nickel-metal hydride battery separator with a thickness of 0.12mm, the degree of sulfonation is 0.7%, and the O / C is 0.041.

Embodiment 3

[0028] The diaphragm base cloth is made of polypropylene fibers, of which the polypropylene fibers with a fineness of 1.1dtex and a length of 38mm account for 95%; the polypropylene fibers with a fineness of 0.3dtex and a length of 38mm account for 5%, and the above fibers are dry carded Process molding, spunlace reinforcement, drying in hot air at 130°C, adjusted to a certain thickness with a rolling mill, and made into diaphragm base cloth, and the surface density of diaphragm base cloth is 55g / m 2 .

[0029] The diaphragm base is placed in the graft modification solution, the weight concentration of the monomer acrylic acid is 3%, an initiator is added, and the graft reaction is fully polymerized under the condition of 95 ° C, washed with deionized water, and dried to obtain For the separator base fabric with a graft ratio of 3%, the thickness of the base fabric was adjusted again with a rolling mill.

[0030] The grafted diaphragm base cloth with adjusted thickness is sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap