High-voltage lead assembly for ultrahigh vacuum device and manufacture method thereof

A high-voltage lead wire, ultra-high vacuum technology, applied in the parts of connecting devices, coupling devices, circuit/collector parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

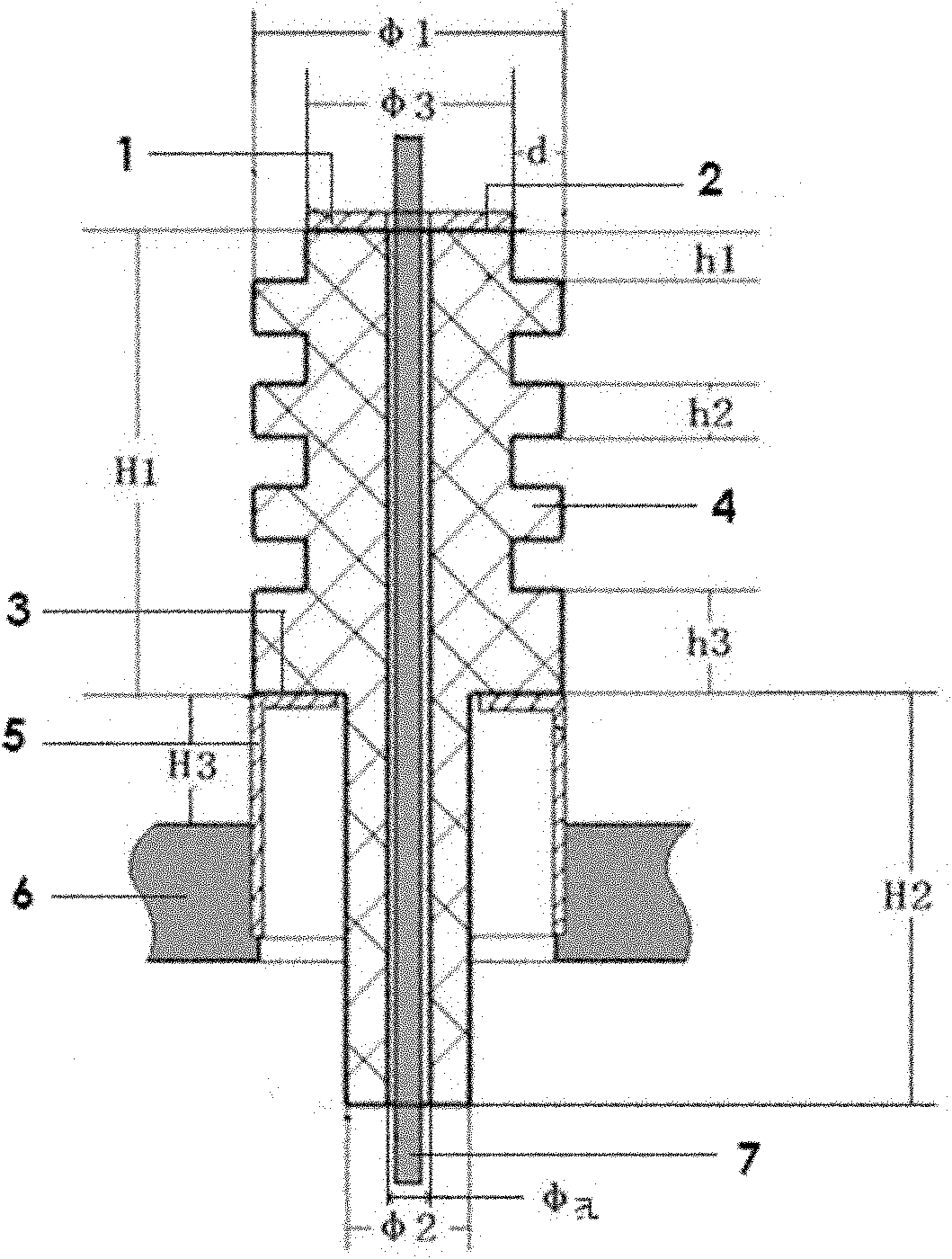

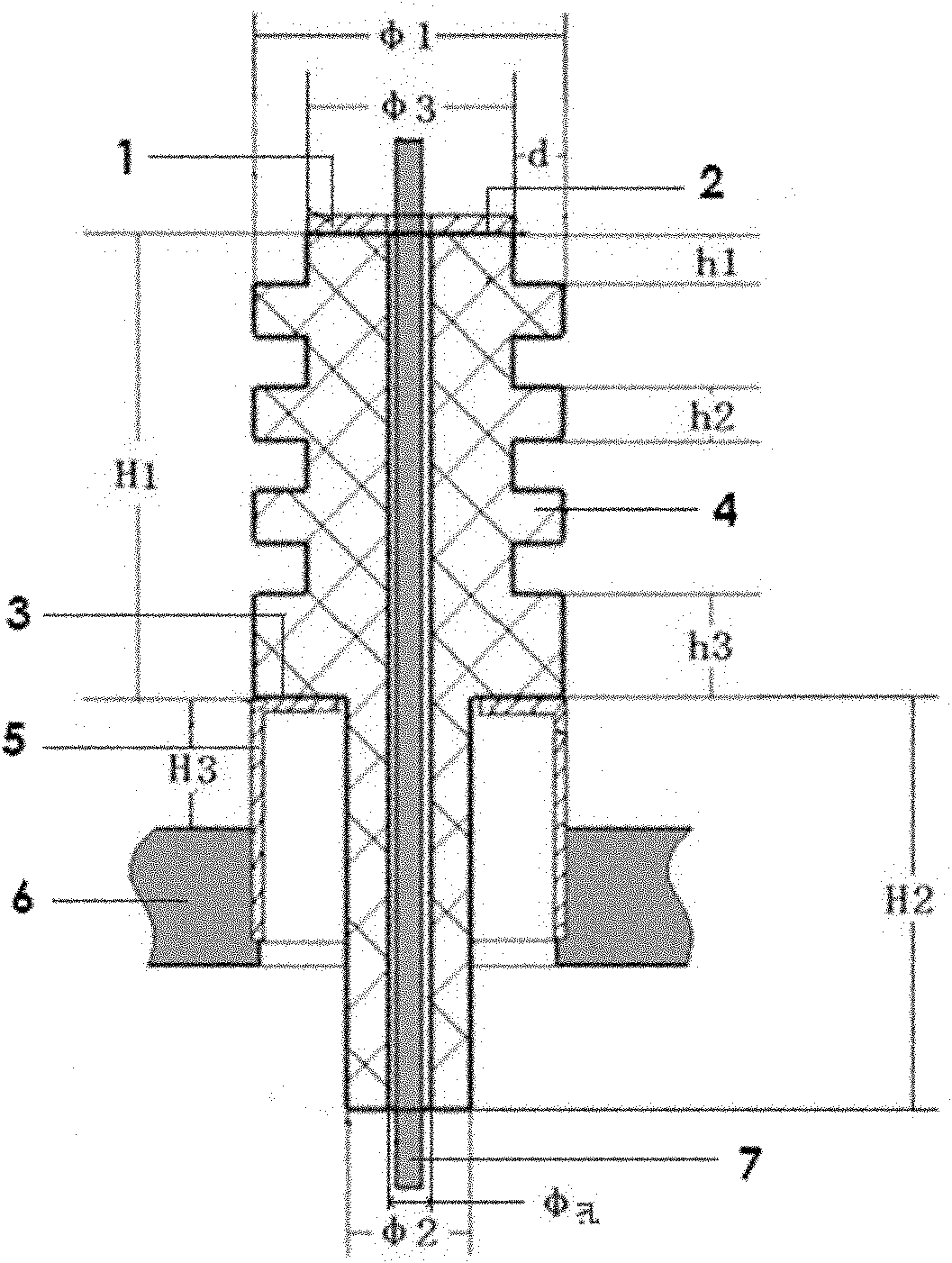

[0050] 1. Press figure 1 Process or purchase 95% alumina insulating porcelain parts for the structure shown 4. The specific structural dimensions are as follows: φ1 = 6.5mmm, φ2 = 4mm, φ3 = 4.5mm, φ 孔 =0.8mm, h1=h2=1.2mm, h3=2.5mm, H1=10.9mm, H2=10mm, d=1mm.

[0051] 2. Using stamping process, press figure 1 The shown structure processes the first porcelain sealing alloy part 1 and the second porcelain sealing alloy part 5 (both are 4J33), and the part thickness (δ) is taken as 0.3mm. Wherein the diameter of the central hole of the first porcelain sealing alloy part 1 is 0.65mm, and the outer diameter is consistent with φ3.

[0052] 3. The metal lead 7 is made of φ0.6mm nickel wire, which has been cleaned and annealed

[0053] 4. Carry out metallization, nickel plating, and hydrogen burning treatment on the sealing surfaces 2 and 3 of the porcelain parts according to the flat sealing structure.

[0054] 5. Clean, nickel-plate and burn hydrogen on the ceramic seal alloy pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com