Inner-source driven comprehensive shape and thickness regulation mill

A driving type, rolling mill technology, applied in the direction of contour control, etc., can solve the problems of difficult to solve the temperature coupling relationship, difficult to realize the rapid response of roll shape, no temperature sensor at the heat source, etc., to enhance the ability to control the shape of the plate, simplify the shape of the plate The structure of regulatory agencies and the effect of simplification of control models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

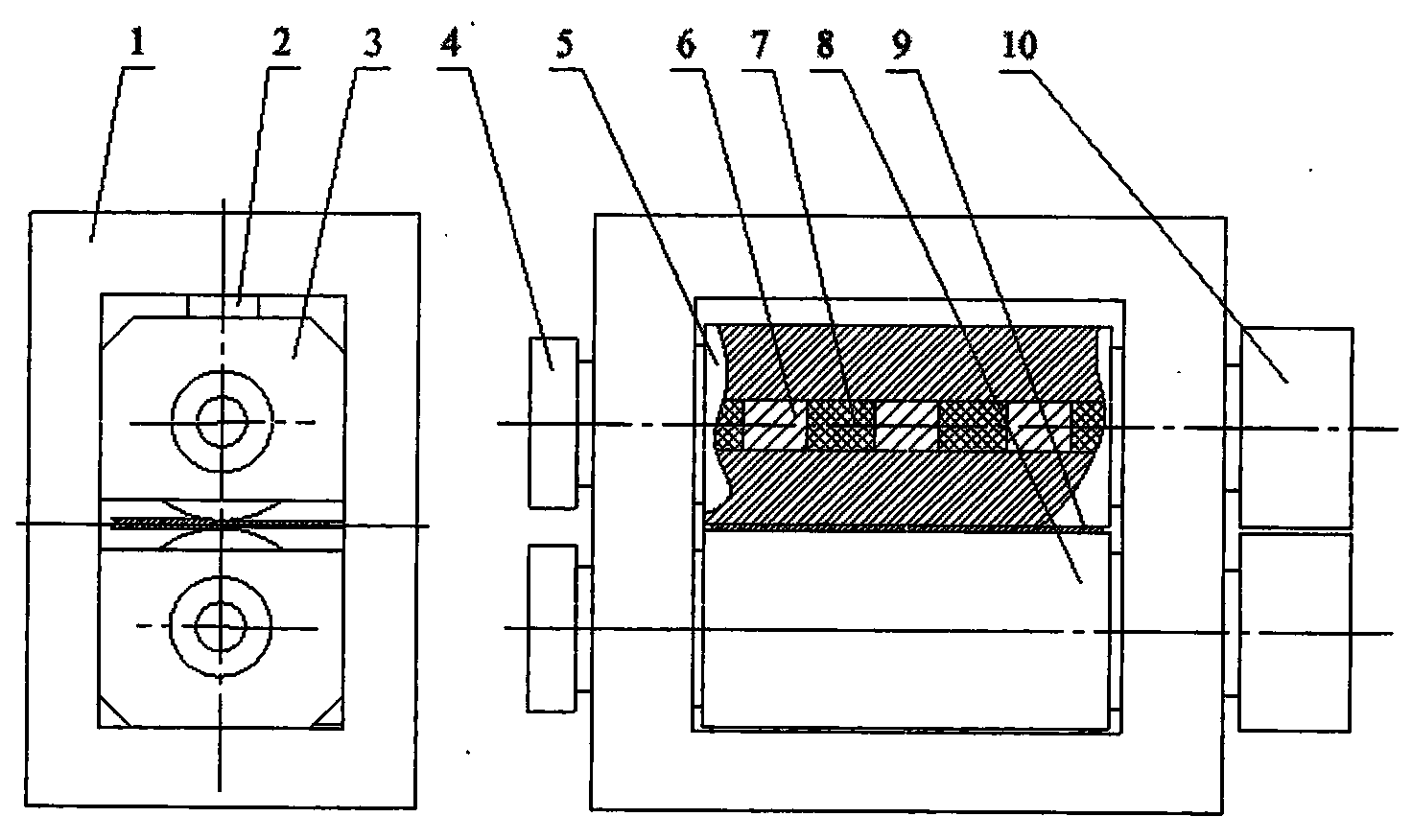

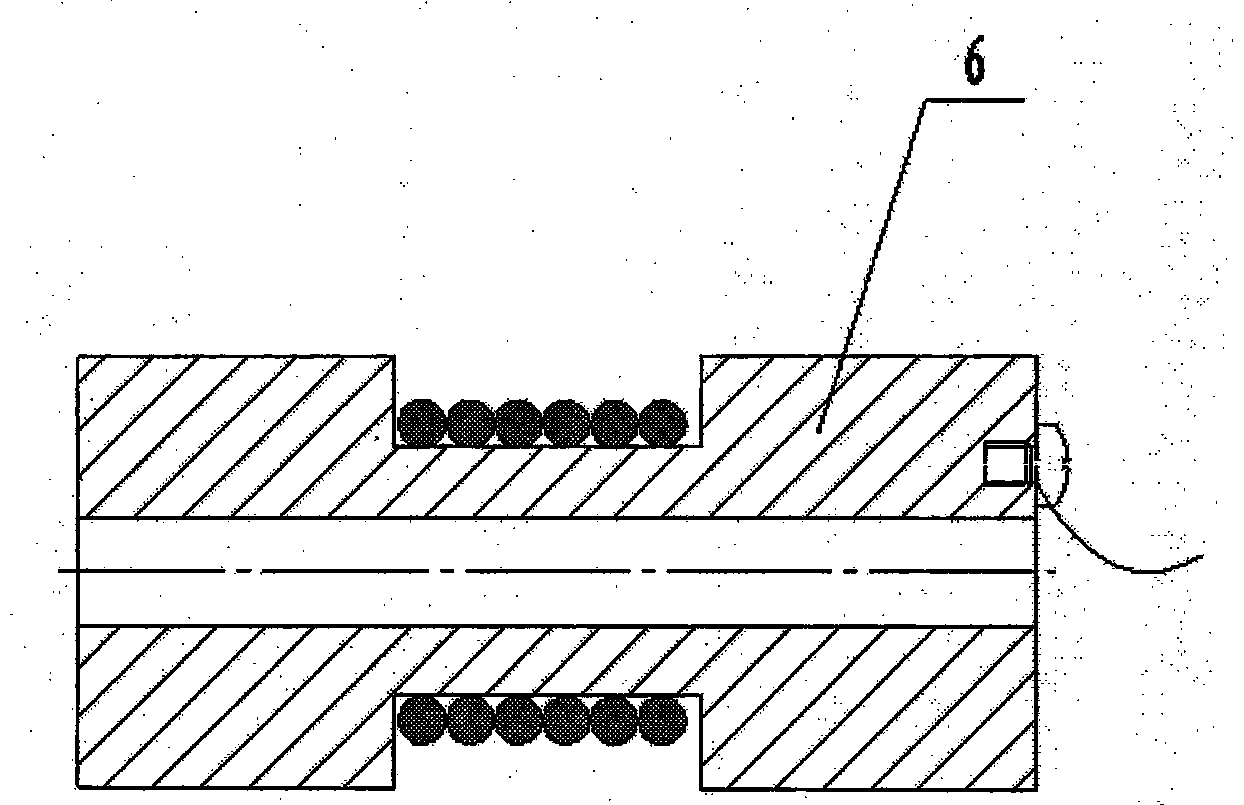

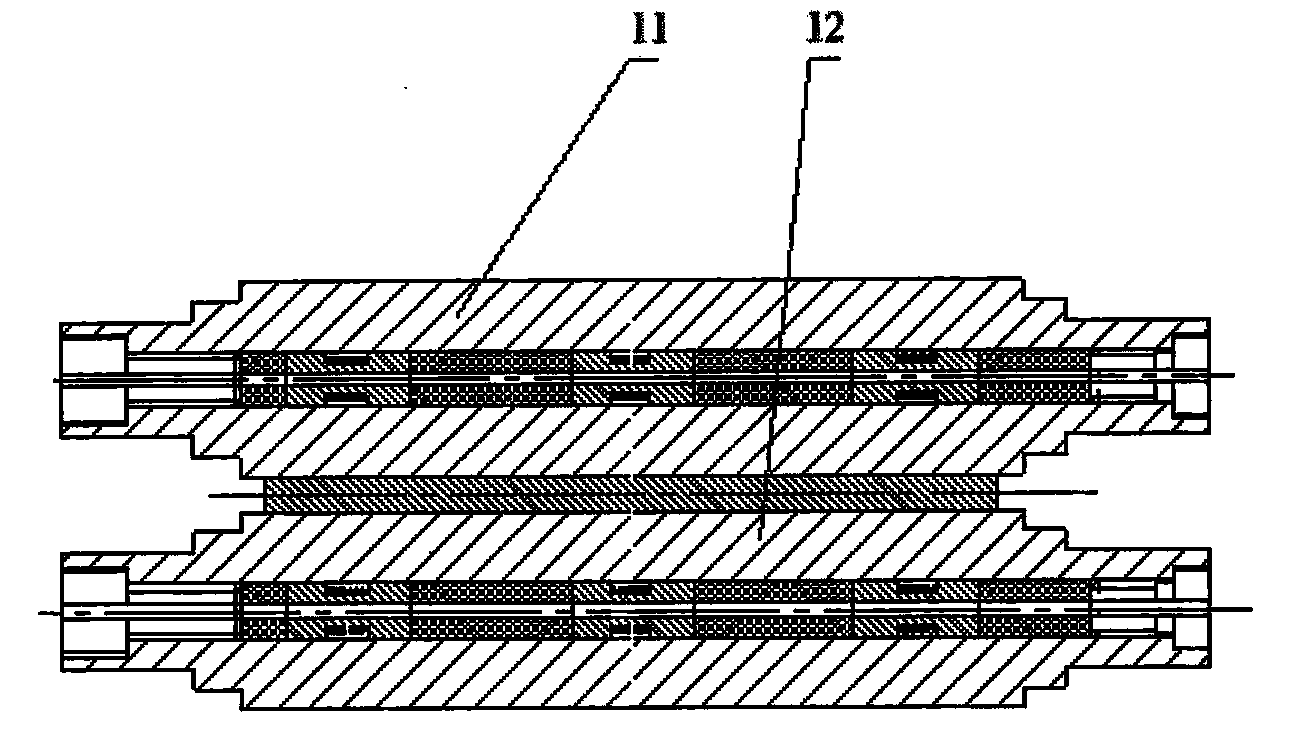

[0031] The structure of an endogenously driven two-roll rolling mill with comprehensive regulation of shape and thickness in this embodiment is as follows: figure 1 As shown, the rolling mill includes a stand 1, a chock 3, a plurality of rolls and a hydraulic cylinder 2 for adjusting the reduction; the plurality of rolls are assembled with the chock 2 to form a roll component, and the rolls Components and hydraulic cylinders 2 are mounted on the frame 1; the plurality of rolls contain roll-type adjustable rolls, and the roll-type adjustable rolls have through-holes; There is an electric thermal expansion rod 6 with a temperature sensor and an insulating spacer ring 7; the end of the adjustable roll is equipped with a slip ring 4 for power supply and signal output; the electric thermal expansion rod 6 interferes with the through hole Assembling, the slip ring 4 is respectively connected to the power supply, temperature detection and control module, and temperature sensor; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com