Flying wheel energy storage type rivetless connection device of servo motor and connection method of connection device

A flywheel energy storage and connection device technology, applied in the field of aluminum plate connection for automobiles, can solve the problems of impact force affecting welding quality, affecting joint quality, and inability to save energy, etc., to improve quality and production efficiency, increase rotational inertia, and reduce vibration. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

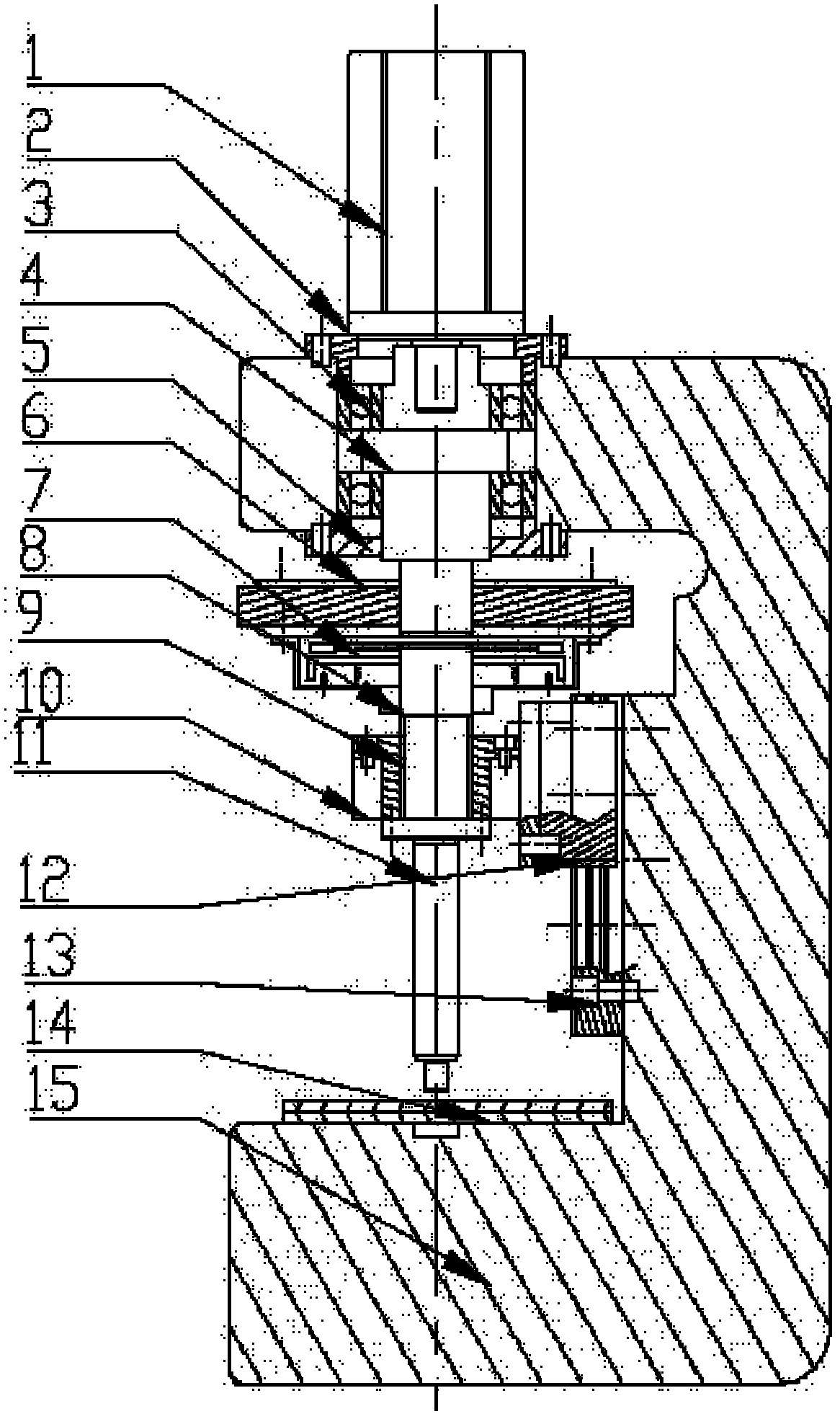

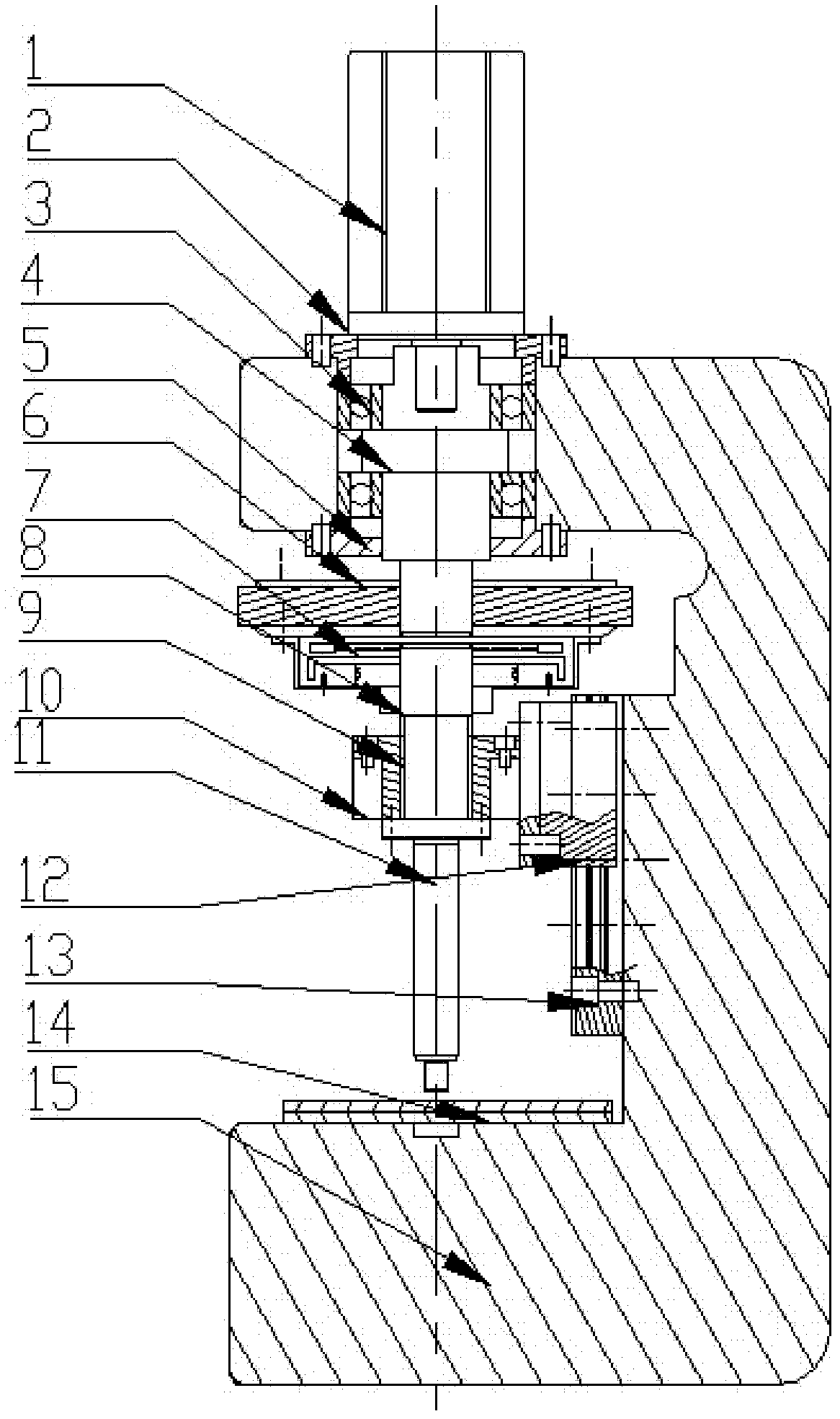

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Referring to the accompanying drawings, a servo motor flywheel energy storage type rivetless connection device includes a motor 1, the output shaft of the motor 1 is connected to the shaft 4 through a key, the motor cover 2 is fixed on the frame 15, and the shaft 4 is fixed by the bearing 3, The bearing cover 5 is on the frame 15, the flywheel 6 is fixed on the shaft 4 by a key, the clutch 7 and the flywheel 6 are connected together by a nut, the clutch 7 is fixed on the optical axis end of the lead screw 8, the lead screw nut 9 and the nut sleeve 10 Fixed, the nut sleeve 10 is fixed on the slider 12, the slider 12 is arranged on the guide rail 13, the guide rail 13 is fixed on the frame 15, the punch 11 is connected with the nut sleeve 10, and the sheet material 14 is placed directly below the punch 11. On the frame 15, the frame 15 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com