Fixture convenient for punching

A convenient and fixture technology, applied in the direction of clamping, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of insufficient accuracy and poor guarantee, and can only process one workpiece, etc., to achieve strong practicability, simple operation, and guarantee The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

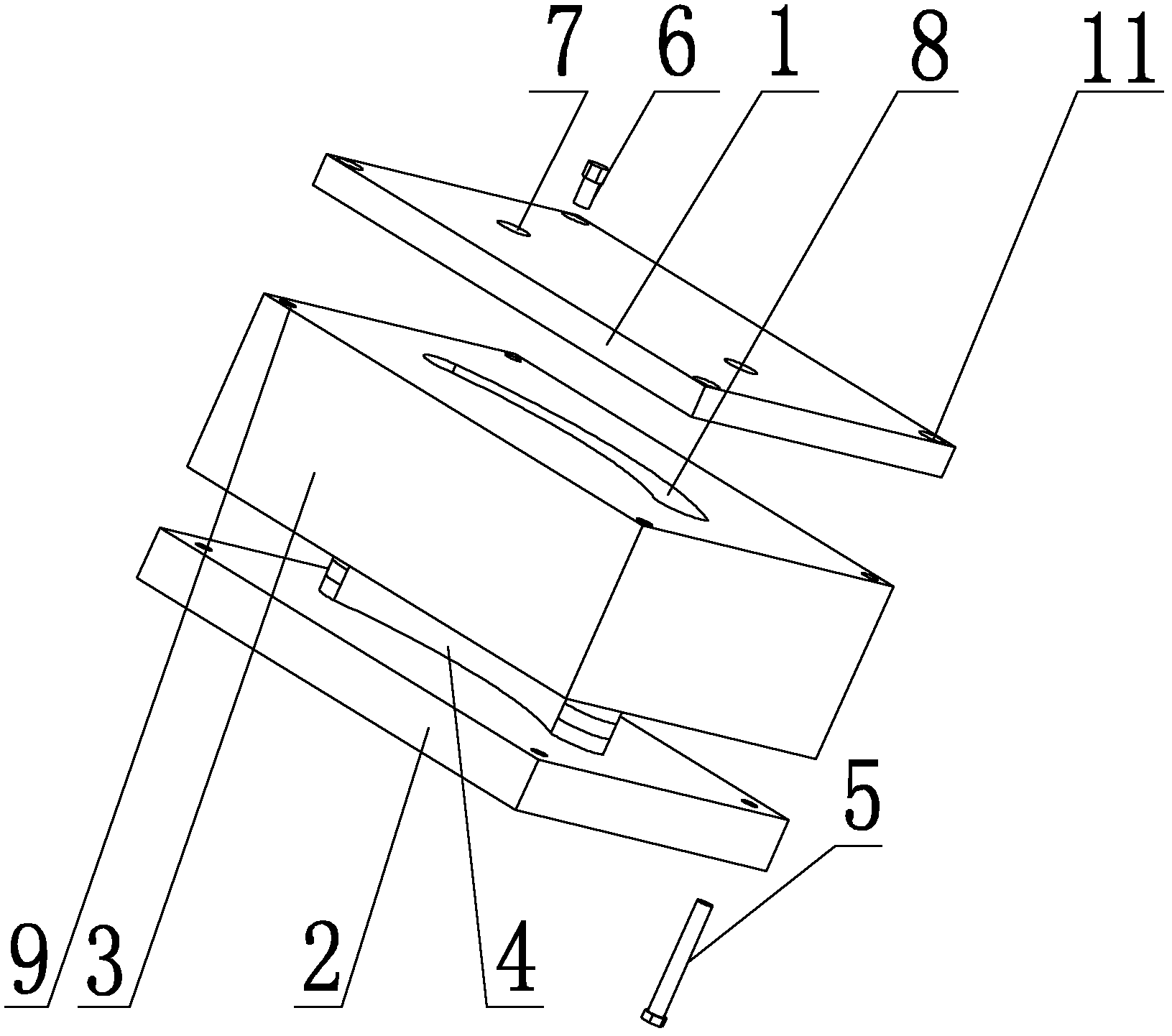

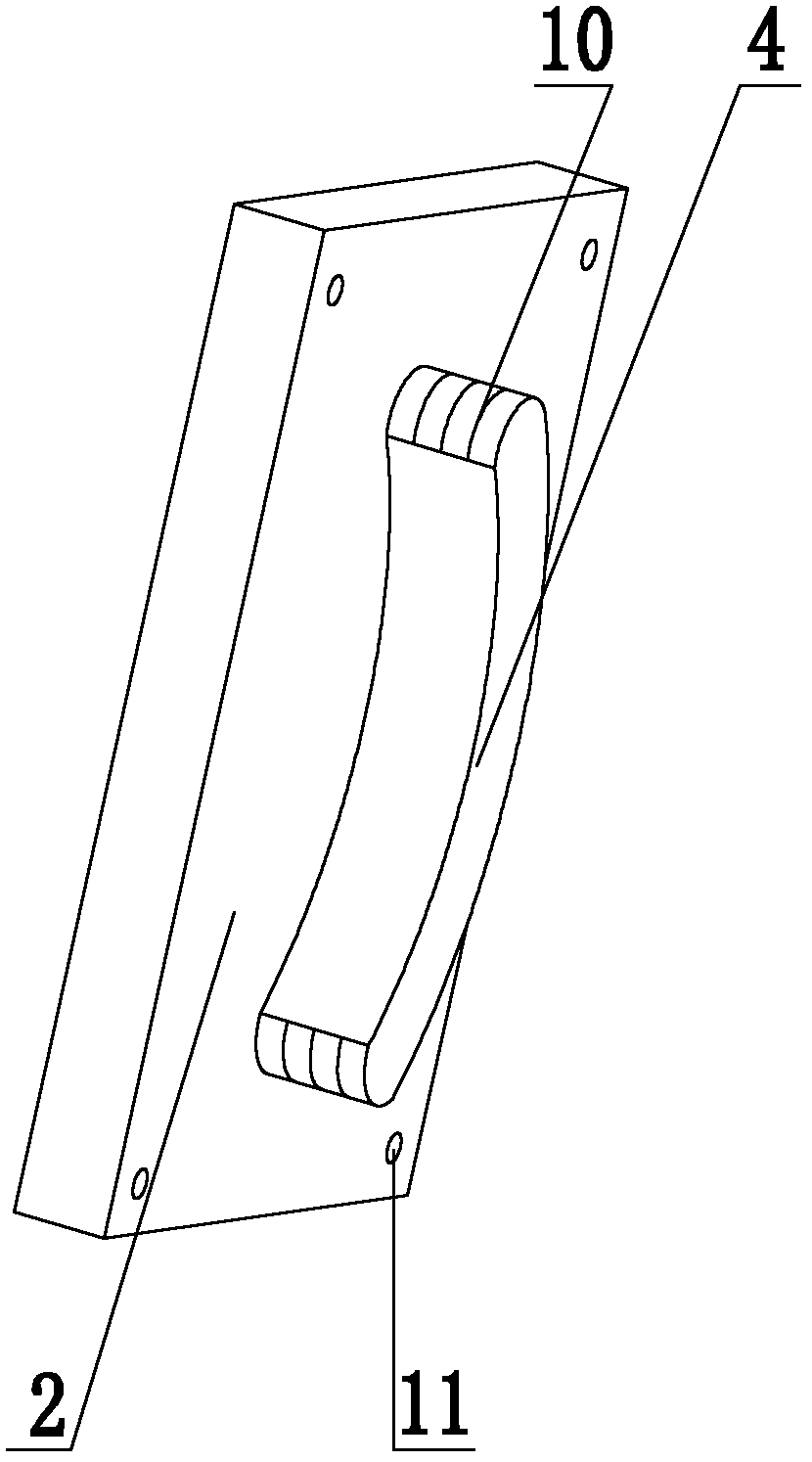

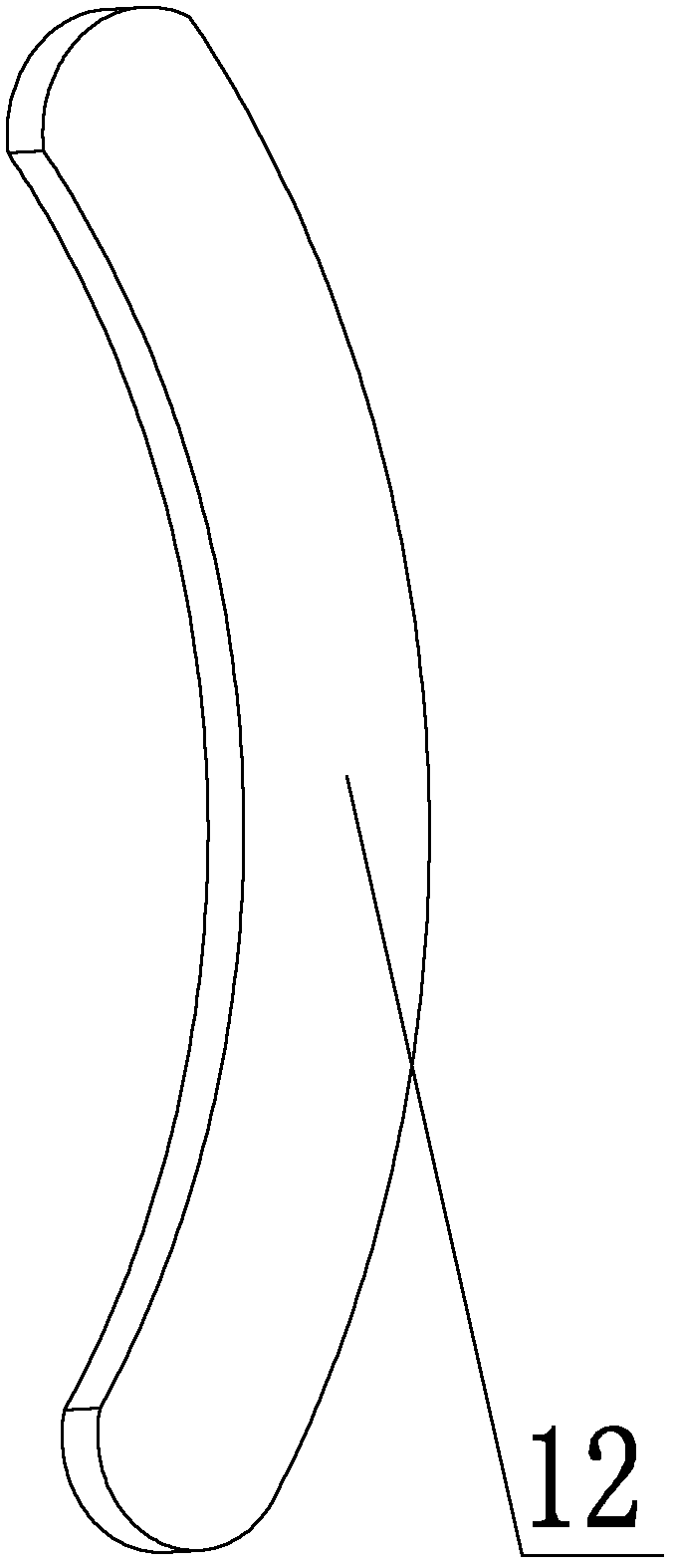

[0015] attached figure 1 It is a clamp for convenient punching according to the present invention, which includes an upper cover body 1, a lower cover body 2, a main body 3, a short screw 6 and a long screw 5; There is a counterbore 11; the center of the main body 3 is provided with an opening 8, and the shape of the opening 8 is the same as that of the workpiece 12; Corresponding to the counterbore 11 of the lower cover 2; the upper cover 1 has two through holes 7, and the position of the through holes 7 corresponds to the position where the workpiece 12 needs to be punched; the upper cover 1 passes through The short screw 6 on the counterbore 11 is fixed with the main body 3; the center position of the lower cover 2 is provided with a protrusion 4 having the same shape as the workpiece; the protrusion 4 is fixedly connected with the lower cover 2, and the protrusion There are scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com