Drum type final trimming saw

An edge sawing machine and drum type technology, applied in the field of sheet metal processing equipment, can solve the problems of inability to saw, the rubber sheet is easy to wear, and the sawing accuracy is reduced, so as to improve the straightness and accuracy, prevent the vibration of the springboard, and increase the stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

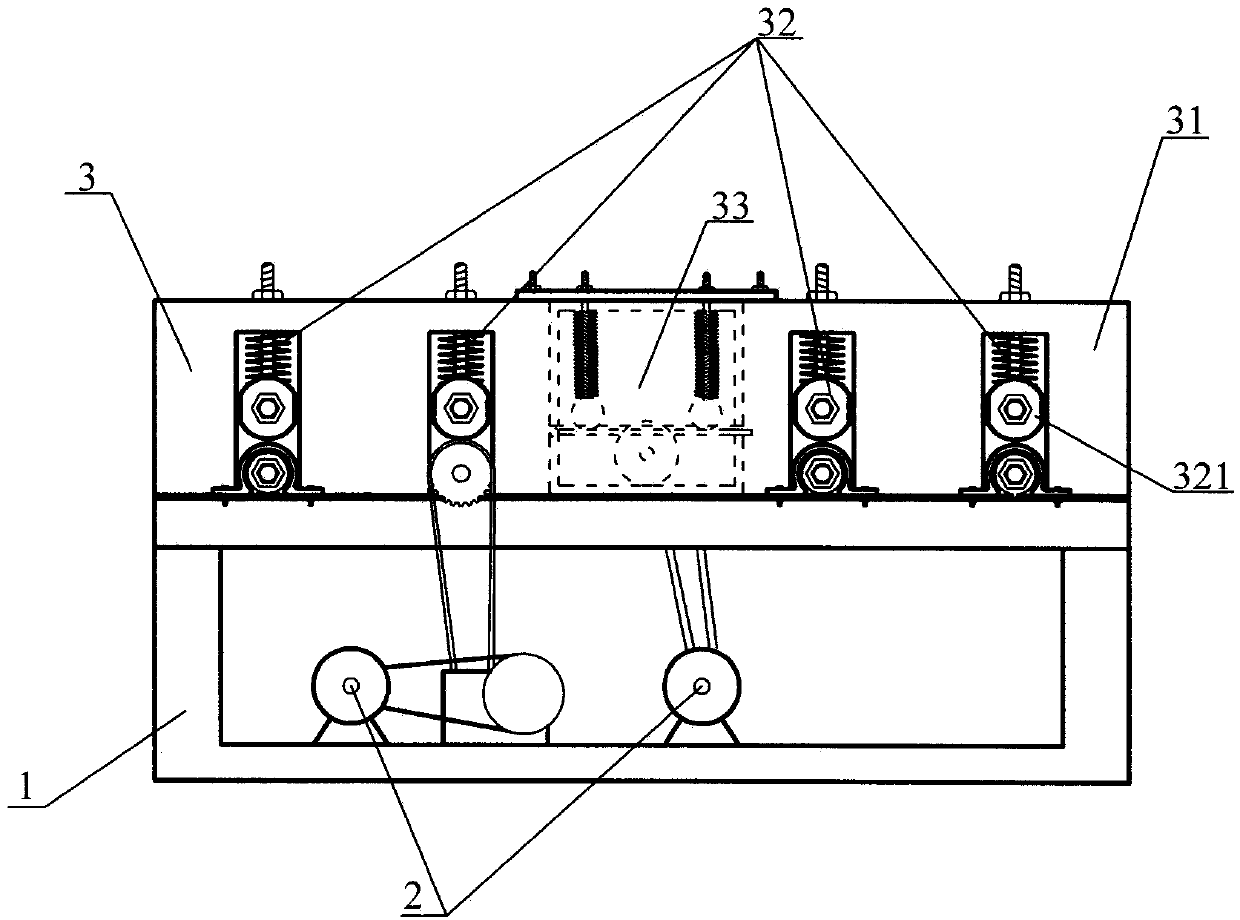

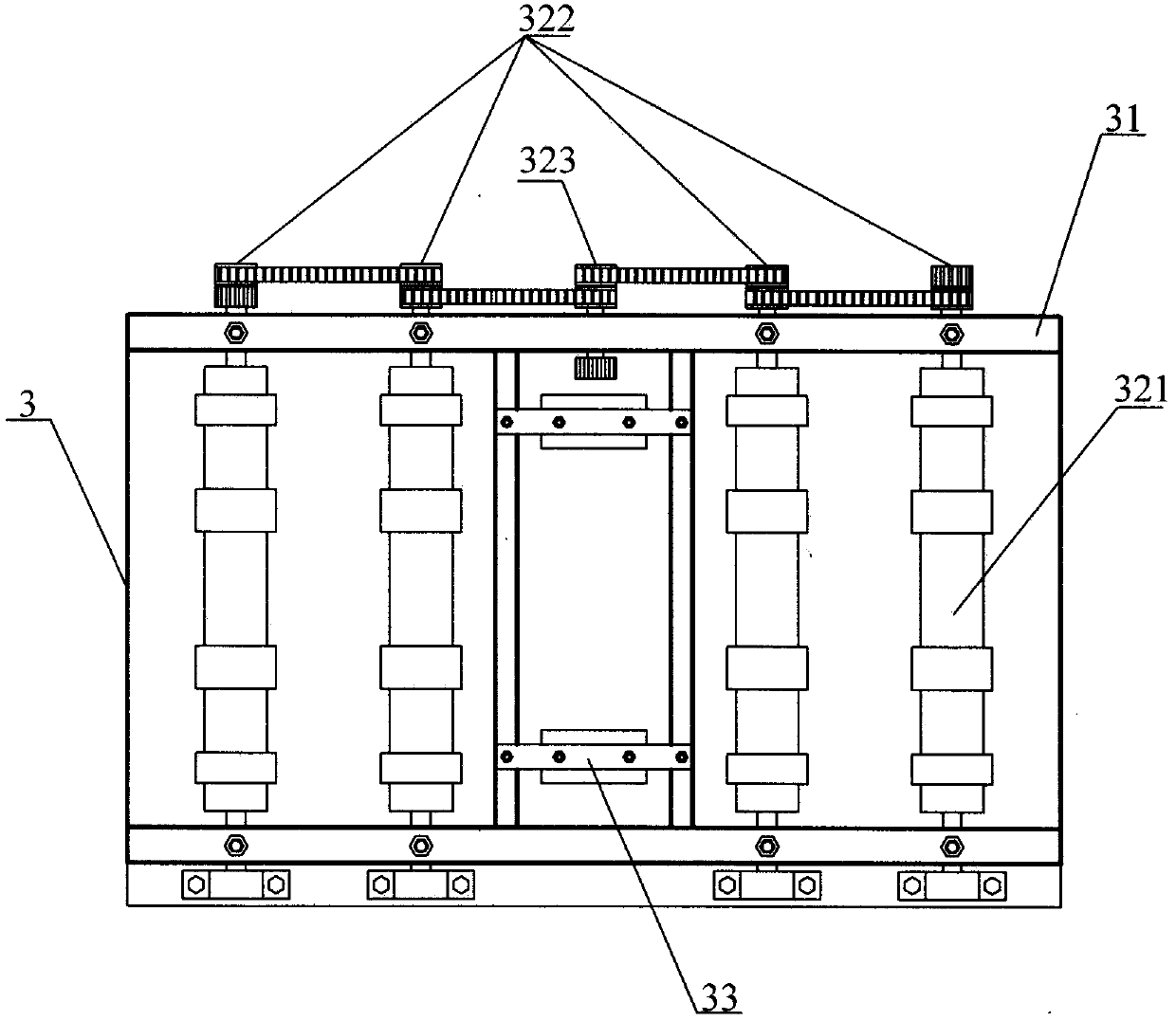

Embodiment 1

[0019] The drum type edge sawing machine is composed of a frame 1, a power mechanism 2, and an edge sawing mechanism 3, wherein the edge sawing mechanism 3 is fixedly connected to the frame 1, and the power mechanism 2 is installed on the frame and connected with the edge sawing mechanism 3 ; The sawing mechanism 3 is composed of a wall panel support 31, a conveying system 32, and a saw edge device 33; There are rectangular holes; the conveying system 32 is four pairs of rollers 321, and each pair of rollers 321 is distributed up and down and installed in the rectangular holes of the wallboard bracket 31; the upper roller 321 is installed on the wallboard bracket 31 through the screw nut connected with the bearing The upper end of the hole, and a spring is installed between the bearing and the upper arm of the wallboard bracket 31 rectangular hole; the lower roller 321 is locked on the lower end of the wallboard bracket 31 rectangular hole by a fixed buckle fixed on the bearing...

Embodiment 2

[0023] The conveying system 32 is two pairs of rollers 321, and the rollers 321 are stepped, and the diameter of the steps at both ends is larger than that of the middle part. Other structures are the same as in Embodiment 1.

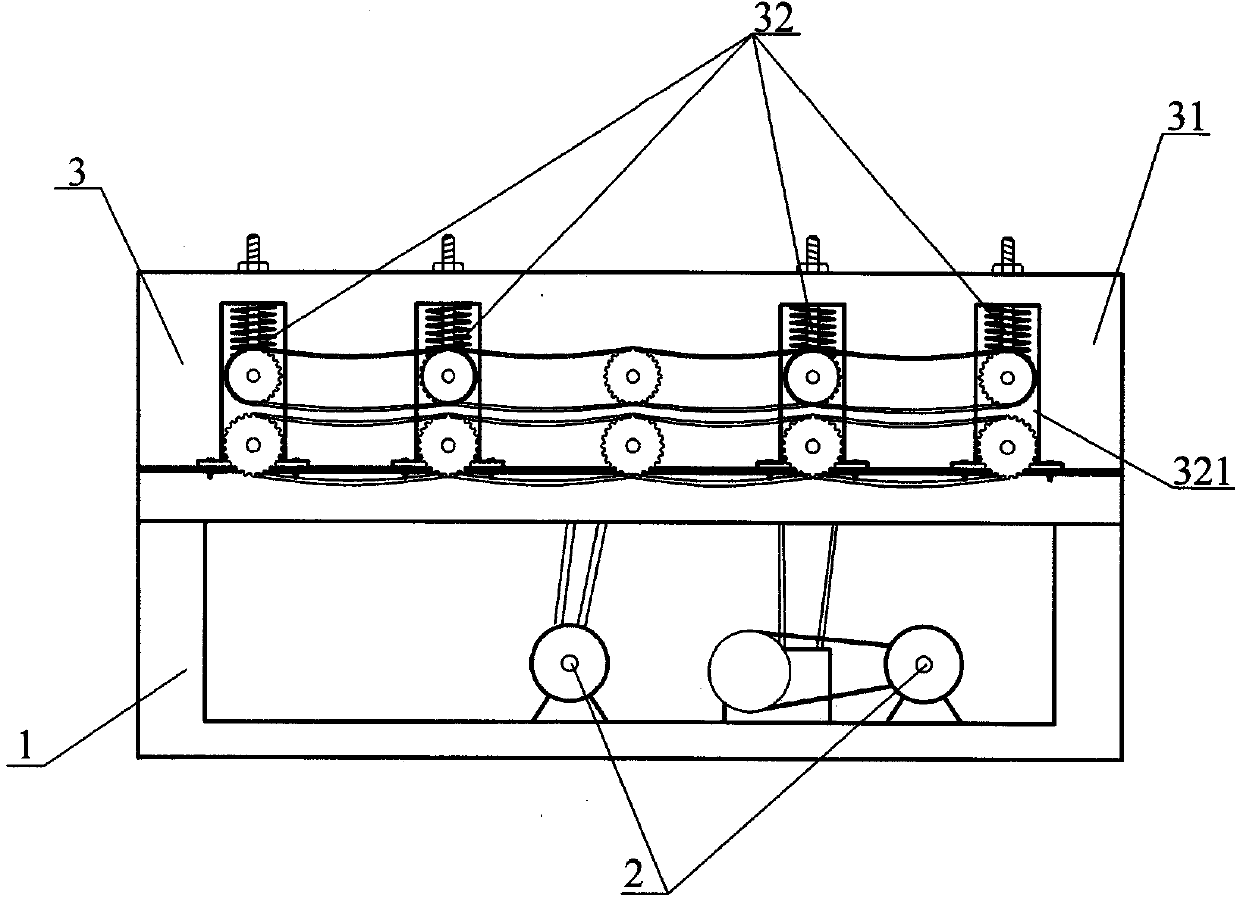

Embodiment 3

[0025] The conveying system 32 includes six pairs of rollers 321, the rollers 321 are stepped, and the diameter of the steps at both ends is equal to the diameter of the steps in the middle. On the wallboard support 31, the bolt holes used to connect with the lower roller 321 are oval or rectangular holes, and the lower roller 321 can adjust its position in the horizontal direction. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com