System for quickly assembling and disassembling auxiliary tyre for motor vehicle

A technology for motor vehicles and tires, which is applied to wheel assembly and disassembly equipment, devices for fixing wheels, wheels, etc. It can solve the problems of inconvenient installation and disassembly, increased fuel consumption, increased tire weight, etc., and achieves the risk of accidental loosening Reduce, lock safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

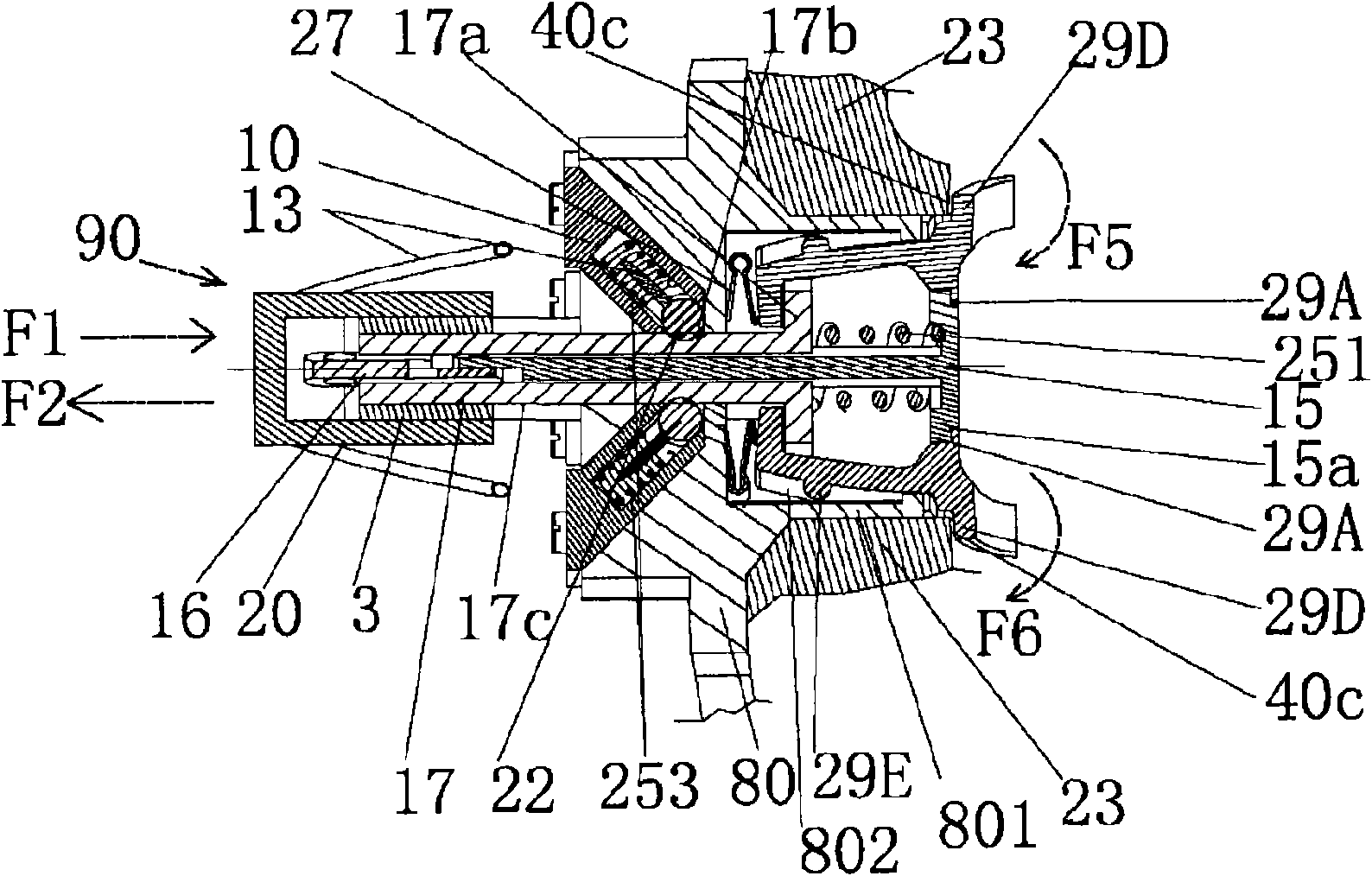

[0141] According to the design idea of the present invention, which is not limited to the first embodiment of the present invention, the locking mechanism includes at least one elastic stopper, and the elastic stopper is used in cooperation with the movable coupling mechanism so that all The primary tire side engaging member remains in the locked position.

[0142] As described below, the locking mechanism can have multiple implementations: elastic stop mode, cam lock mode, ratchet pawl mode, gear meshing mode, connecting rod locking mode and other known locking and locking methods that can be used in the present invention. / or locking method.

[0143] Optionally, the elastic stopper includes a pneumatic piston or a hydraulic piston.

[0144] Preferably, according to the design idea of the present invention, not limited to the first embodiment of the present invention, the elastic stopper is a one-way locking member, and the one-way locking member includes a lock block 22...

Embodiment approach

[0152] Preferably, according to the design concept of the present invention, which is not limited to the first embodiment of the present invention, the one-way locking member includes a compression spring 253, and the compression spring applies a force to the lock block 22. The locking position of the locking block 22 is ensured by this force to ensure that the locking block 22 is always in contact with the first friction contact surface 17c and the second friction contact surface 105 .

[0153] Advantageously, without being limited to the first embodiment, the one-way locking member can move between a working position and a non-working position, and in the working position, the first frictional contact surface 17c can only move in the first direction F 1 One-way movement, in the non-working position, the first frictional contact surface 17c can move in the first direction F 1 and the second direction F2 Move freely in both directions.

[0154] Such as Figure 2b As shown, a...

no. 1 example

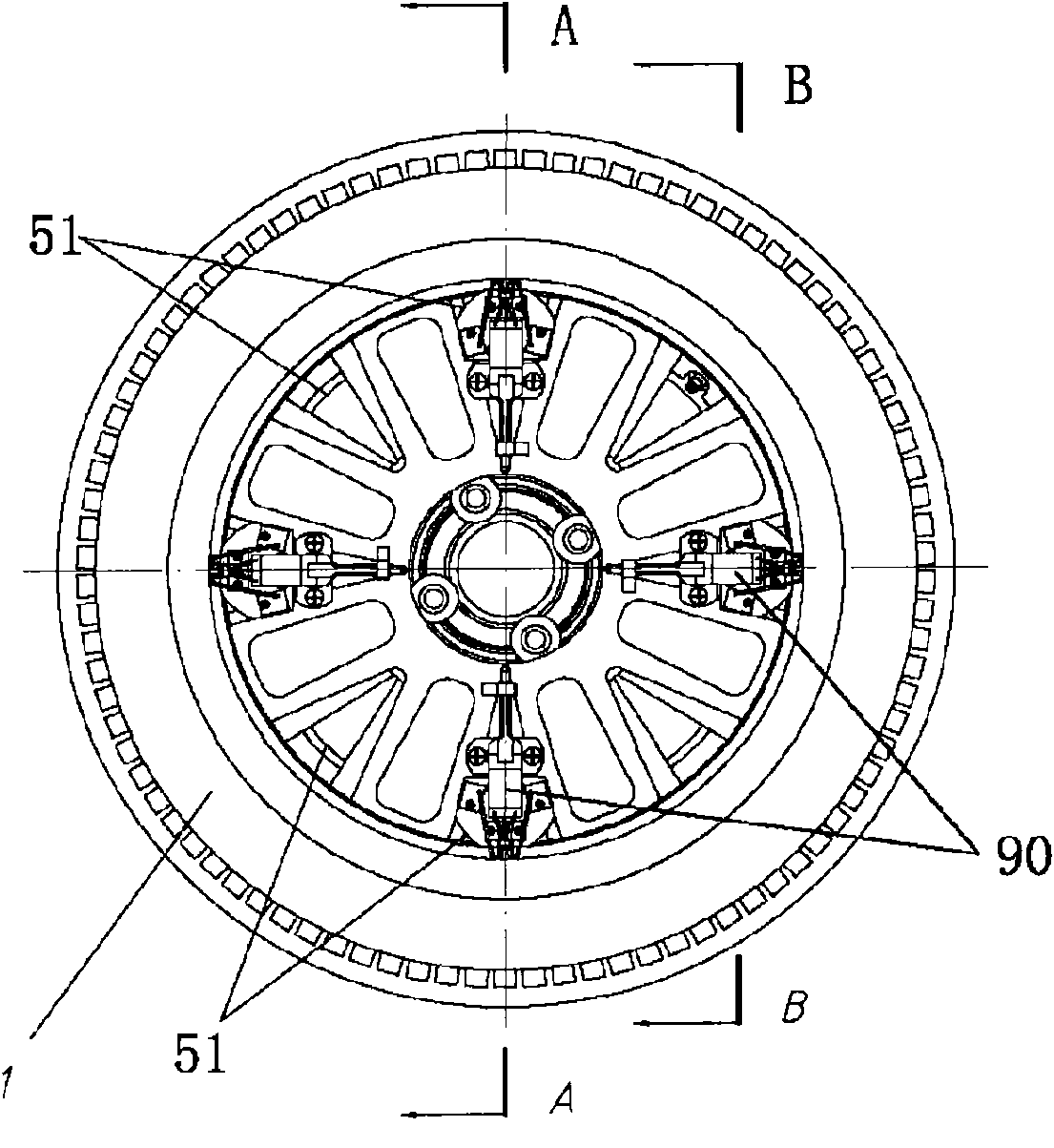

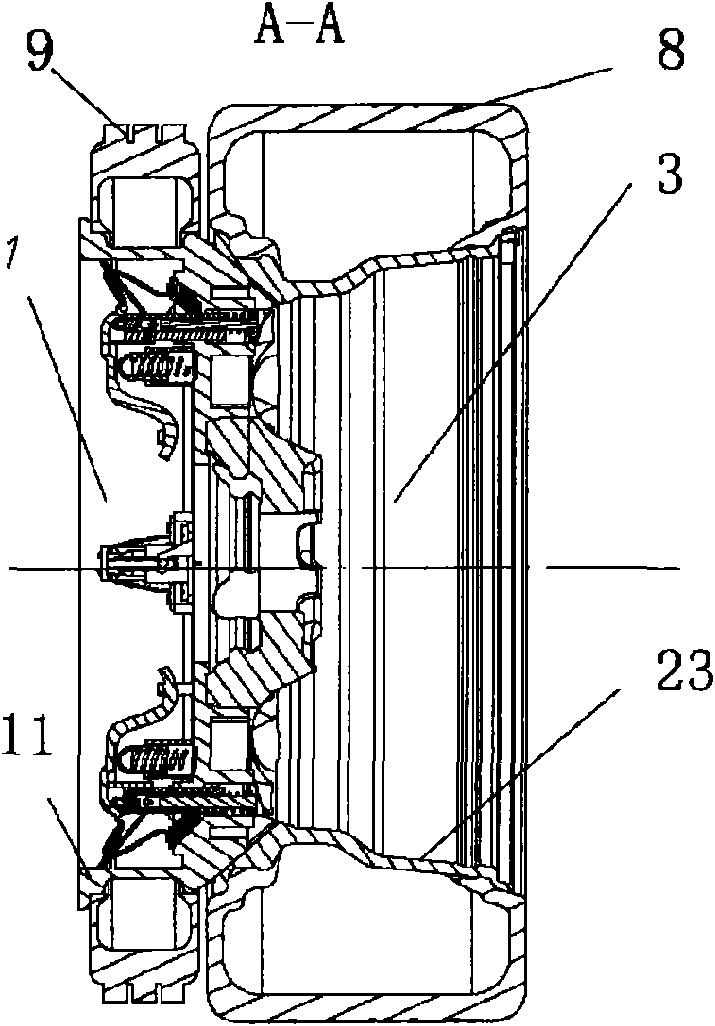

[0183] According to the first embodiment of the present invention, the working principle of the installation and disassembly of the quick installation and disassembly system 90 is as follows:

[0184] Steps to install auxiliary tire 1 to main tire 3:

[0185] - Place the unpowered jack 50 in front of the main tire 3 to be installed with auxiliary tires, drive the car on the unpowered jack 50, and lift the main tire 3 off the ground;

[0186] - Put the main tire-side abutment part of the locking device 90 in the disengaged position, the articulation mechanism in the hooked position, and the locking mechanism in the unlocked position. Disengage the pressing rod 20 from the lock hook 21, turn the pressing rod 20 to expose the unlocking head 16 of the inner locking rod; Open the hole 16B, pull up the unlocking head 16 of the inner locking rod, let the return hook 16A used by the unlocking lock plate 29 of the inner locking rod 16 be hooked on the top of the outer locking rod 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com