Automatic ceramic tile feeding device special for polishing of ceramic tiles

A ceramic tile and automatic technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of poor placement of ceramic tile blanks, low production efficiency, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

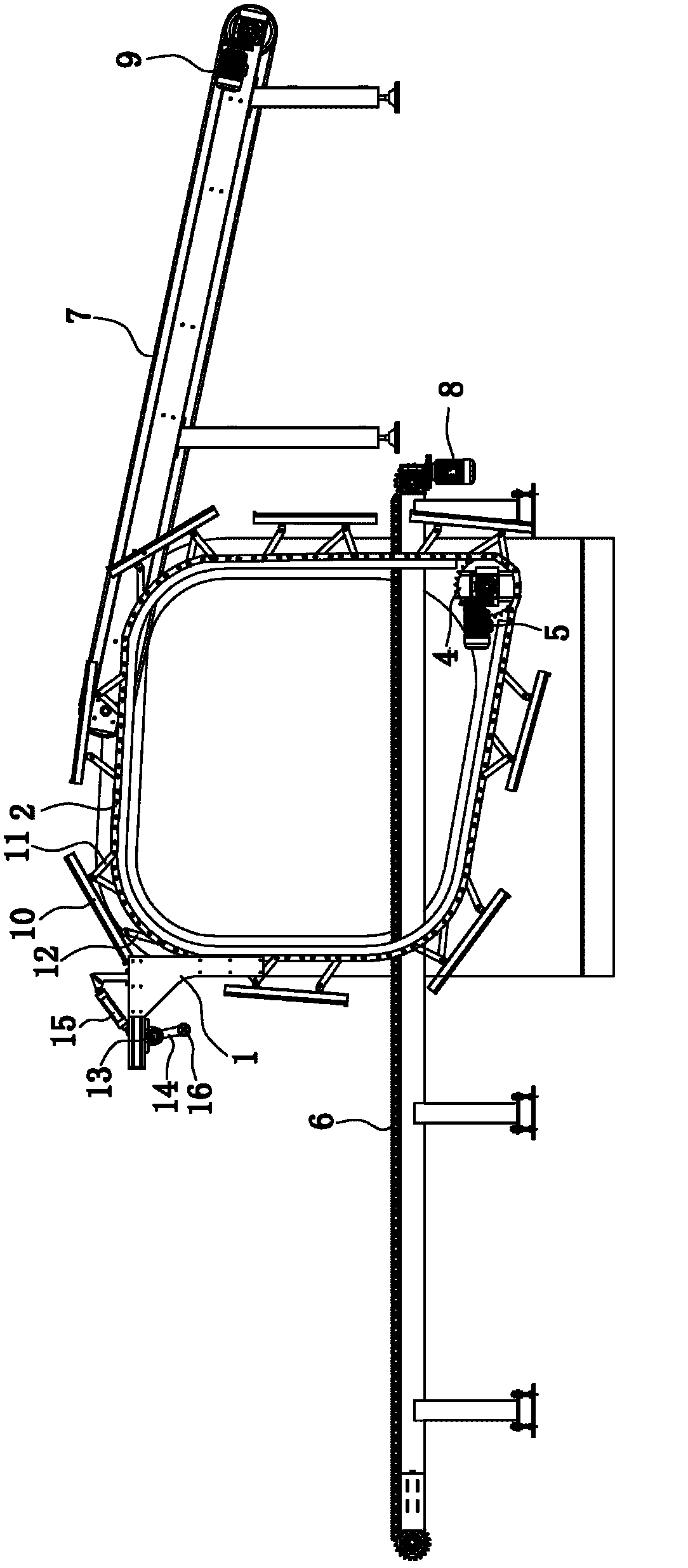

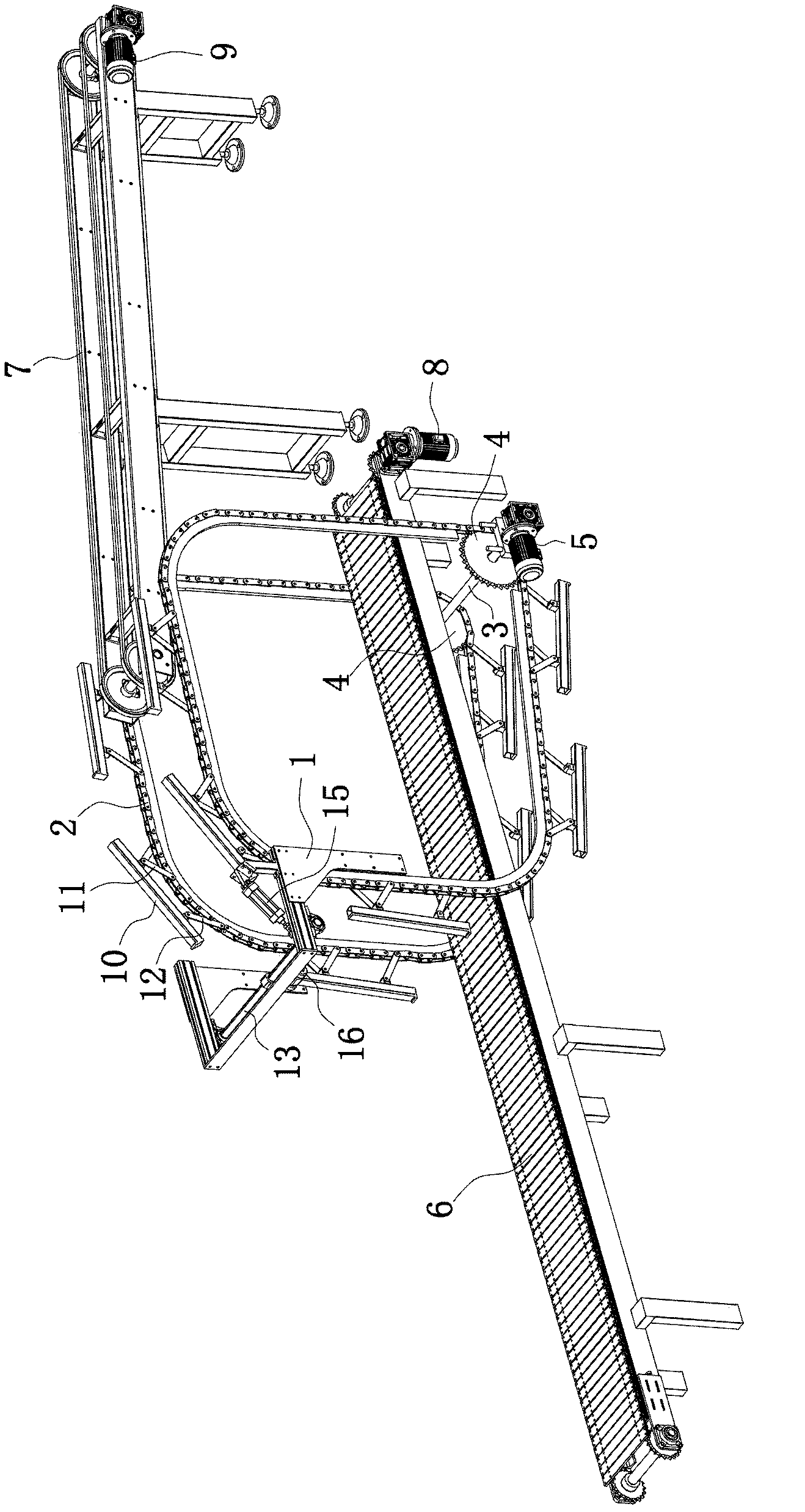

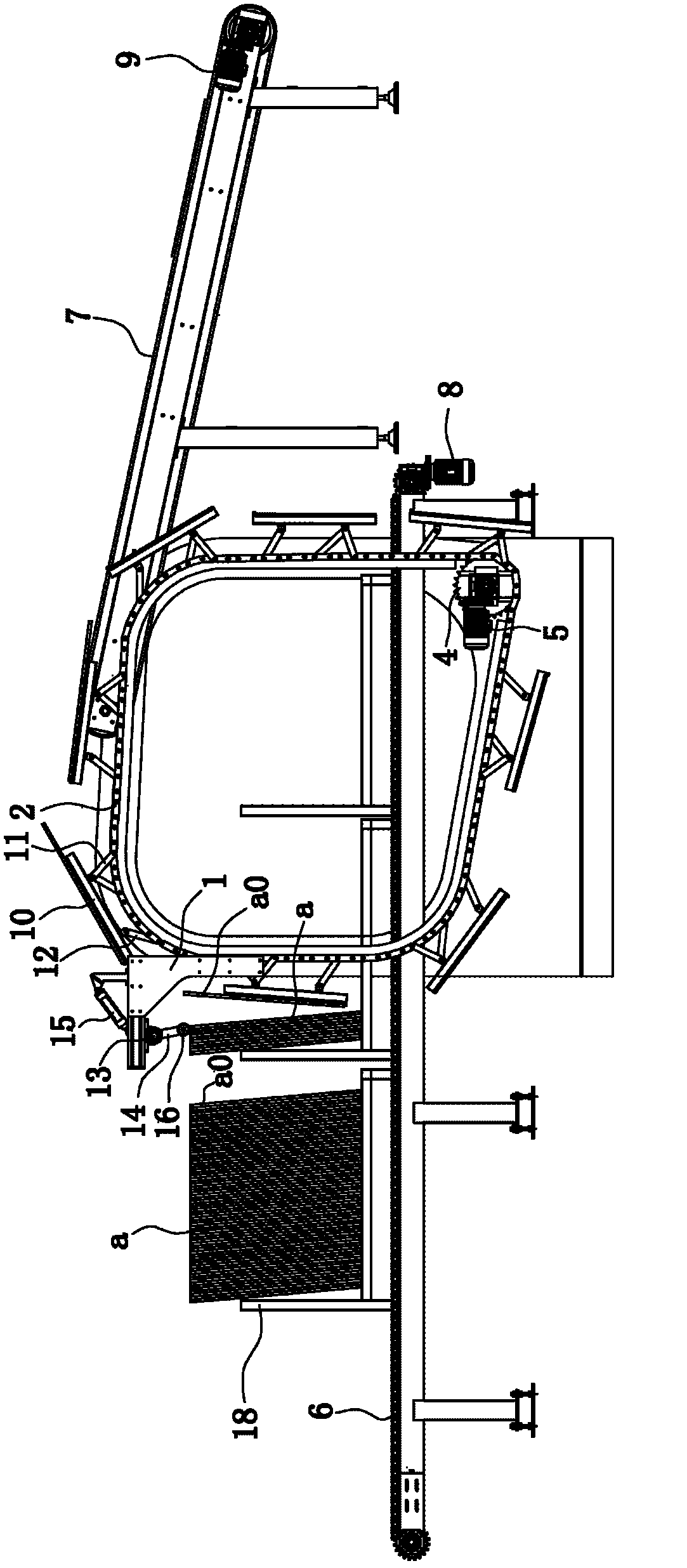

[0016] Below in conjunction with accompanying drawing, the utility patent is further described.

[0017] The special automatic brick loading device for ceramic tile polishing of the present embodiment includes a frame 1, a brick pile transmission mechanism, a loop circulation mechanism and a brick connection transmission mechanism. The plane surrounded by the chains 2 is set vertically, and the transmission shaft 3 is arranged on the frame 1. Two sprockets 4 are sleeved on the transmission shaft 3. Each endless chain is equipped with a sprocket, and one end of the transmission shaft 3 is provided with a drive Motor 5, drive motor 5 to drive transmission shaft 3 to rotate, the brick pile transmission mechanism is a tank chain 6, the tank chain 6 passes between the lower parts of the two circulation chains 2 of the loop-back circulation mechanism, and the brick-connecting transmission mechanism is a brick-connecting transmission belt 7. The tank chain 6 and the brick-connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com