Multistage anaerobic reaction device and method for preparing methane by utilizing same

An anaerobic reaction device and methane technology, applied in biochemical equipment and methods, anaerobic digestion treatment, gas production bioreactors, etc., can solve the problem of not considering the external suitable conditions for anaerobic degradation microorganisms, and the anaerobic degradation efficiency is not high enough , Methane content is not high enough to achieve the effect of high reaction efficiency, strong impact load capacity and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

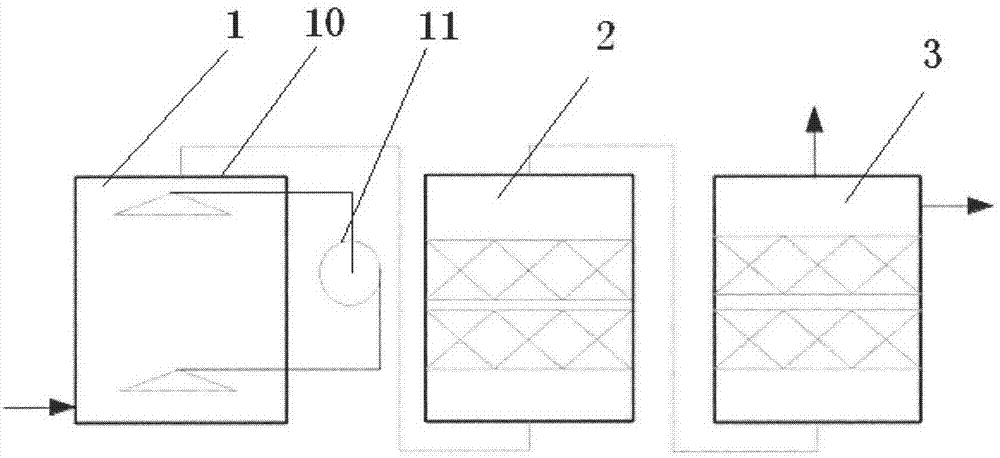

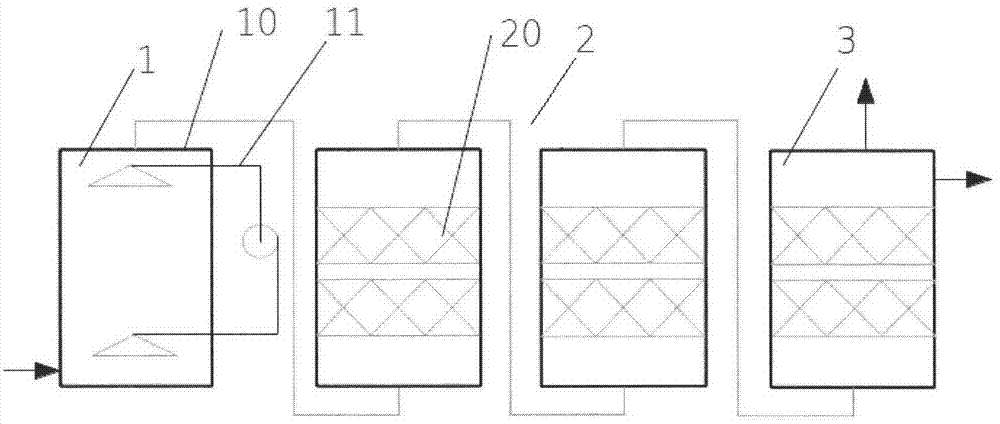

[0026] See figure 1 , A multi-stage anaerobic reaction device, comprising a first-stage reaction tank 1, a second-stage reaction tank 2 and a third-stage reaction tank 3 arranged end to end in sequence, the first-stage reaction tank 1 is a stirred tank, and the second The second-stage reaction tank 2 is a stirred tank, and the third-stage reaction tank 3 is a stuffed tank. In this embodiment, the first-stage reaction tank 1 is a stirred tank, the second-stage reaction tank 2 is a packed tank, and the third-stage reaction tank 3 is a packed tank.

[0027] With the device of the present invention, in each reaction tank, no matter solid, liquid or gas, there is no channel to return directly from the back stage of the reactor to the front stage, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com