Method for preparing proton conductor ceramic by low-temperature densification

A proton conductor and densification technology, which is applied in the field of preparation of proton conductor ceramics, can solve the problems of high cost, uneven distribution of sintering aids, element segregation, etc., and achieve the goal of reducing production cost, possibility, and element segregation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

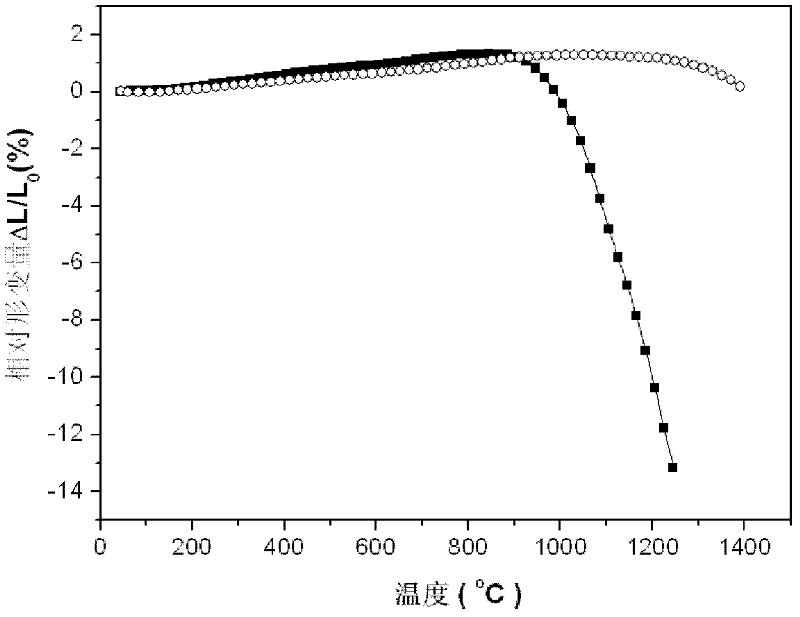

[0016] Specific implementation mode 1: This implementation mode is a method for preparing proton conductor ceramics by low-temperature densification, which is specifically completed according to the following steps:

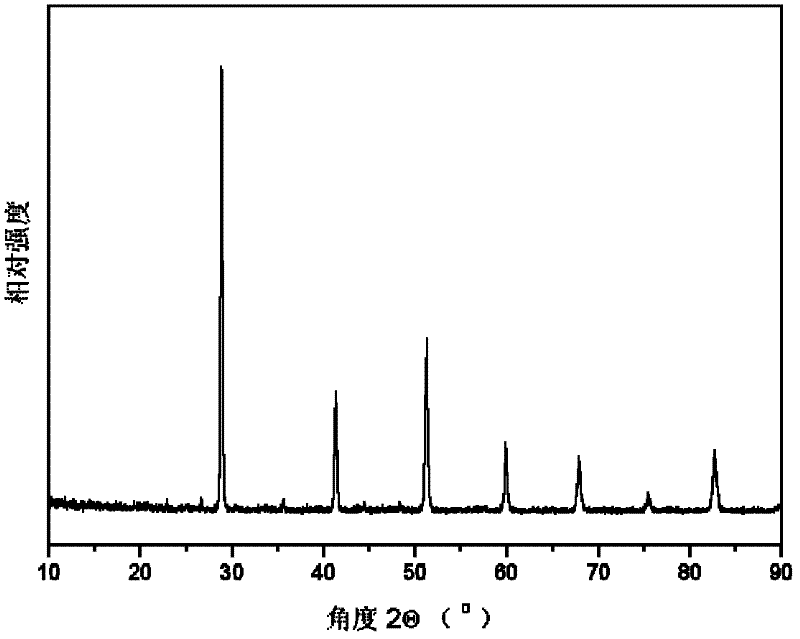

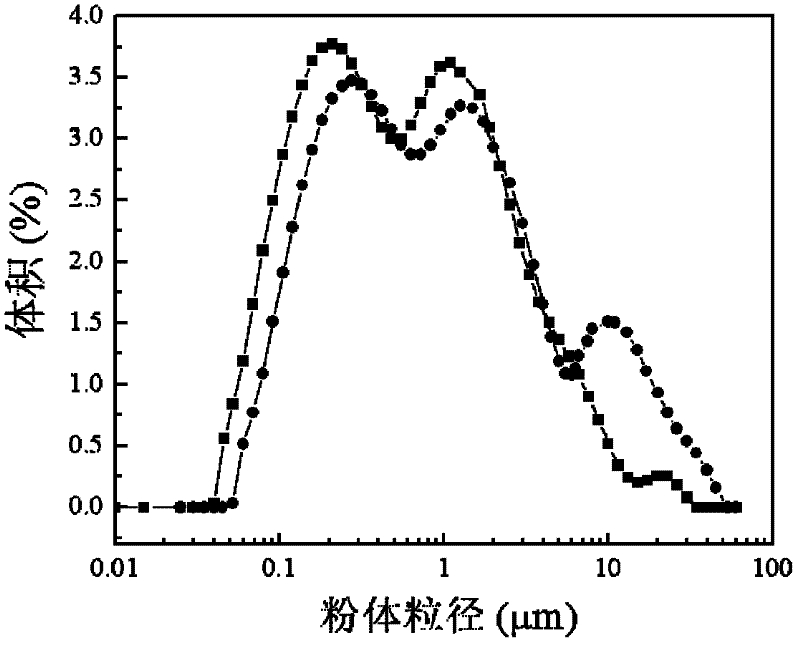

[0017] 1. According to the general structural formula M m Ce x Zr y R z o 3-δ , according to the ratio of M element, Ce element, Zr element and R element in molar ratio of m:x:y:z, weigh the nitrate raw materials, and then synthesize them by sol-gel method to obtain a gel-like synthetic product. The colloidal synthetic product is baked at a constant temperature of 150°C to 250°C for 8h to 12h to obtain a black powder, and finally the black powder is calcined at 1000°C to 1200°C for 4h to 8h to obtain M m Ce x Zr y R z o 3-δ Powder; 2. First, M m Ce x Zr y R z o 3-δ The powder is impregnated, and then filtered to obtain impregnated M m Ce x Zr y R z o 3-δ powder; 3. Firstly, the impregnated M m Ce x Zr y R z o 3-δ The powder is heat-treated ...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the sol-gel method described in the step 1 is specifically completed according to the following steps: first nitrate raw materials are added in the EDTA-ammonia solution, Then add citric acid to form a mixed solution, and heat it under the condition of a constant temperature water bath with a stirring speed of 80 rpm to 250 rpm and 70 °C to 90 °C until a gel is formed to obtain a gel-like synthetic product; In the EDTA-ammonia solution added, the ratio of EDTA mole to the total mole of metal ions in the mixed solution is (1~2): 1; wherein the mol ratio of the citric acid added and the total mole of metal ion in the mixed solution is ( 1~2):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dipping treatment described in step two is specifically completed according to the following operations: the M m Ce x Zr y R z o 3-δ The powder is completely immersed in the impregnating solution for 1min to 30min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com