Manufacturing method of oil-wax feel Yangbuck

A manufacturing method and technology of sheepskin leather, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of ordinary sheepskin leather such as poor wear resistance, lack of change in touch, and poor hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

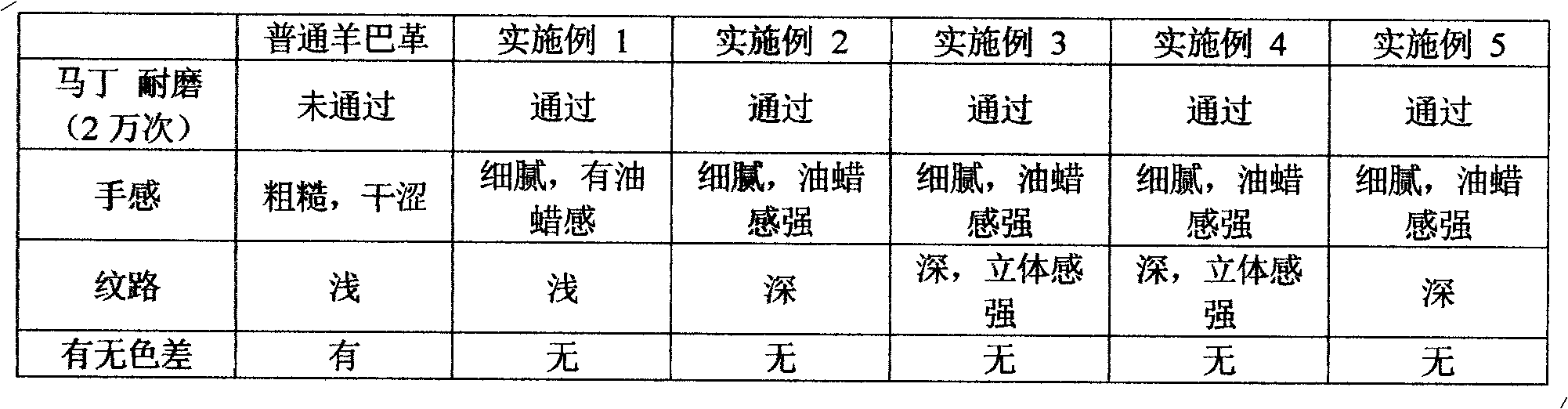

Examples

Embodiment 1

[0050] (a) Use warp-knitted fabric, raised on the back, with a thickness of 0.7mm and a density of 210g / m 2 , made of ordinary wet bottom billet.

[0051] (b) Roll coating of foaming slurry. The formula ratio of foaming slurry is calculated by mass as:

[0052] Foaming resin (HX-8030): 100 parts,

[0053] Solvent (butanone): 45 parts,

[0054] Microsphere foaming powder (FN 100D): 2 parts,

[0055] Oil wax feel agent (LS-50-104): 1 part,

[0056] Matting agent (TS-100): 0.3 parts,

[0057] BLPP509: 1.5 parts,

[0058] BLPP293: 1.5 parts,

[0059] BLPP102: 2 parts,

[0060] The coating weight is 200g / m 2 .

[0061] (c) drying at a temperature of 100°C.

[0062] (d) Printing oil waxy paste. The formula ratio of the oily waxy slurry is calculated by mass as:

[0063] Resin (HT-2280): 100 parts,

[0064] Solvent (DMF): 60 parts,

[0065] Oil wax feel agent (LS-50-104)): 1 part,

[0066] Matting agent (TS-100): 0.1 parts,

[0067] BLPP509: 1 part,

[0068] BLPP293...

Embodiment 2

[0074] (a) Woven fabric, napped on the back, 0.75mm thick, 200g / m2 density 2 , made of ordinary wet bottom billet.

[0075] (b) roll coating foaming slurry, the formula ratio of foaming slurry is calculated as:

[0076] Foaming resin (HX-8030): 50 parts,

[0077] Foaming resin (HX-8080): 50 parts,

[0078] Solvent (butanone): 45 parts,

[0079] Solvent (ethyl acetate): 30 parts,

[0080] Microsphere foaming powder (MSH 330): 4 parts,

[0081] Oil wax feel agent (LS-50-104): 3 parts,

[0082] Matting agent (TS-100): 1 part,

[0083] BLPP509: 1.5 parts,

[0084] BLPP293: 1.5 parts,

[0085] BLPP102: 2 parts,

[0086] The coating weight is 400g / m 2 .

[0087] (c) drying at a temperature of 110°C.

[0088] (d) Printing oil waxy paste. The formula ratio of the oily waxy slurry is calculated by mass as:

[0089] Resin (HT-2280): 50 parts,

[0090] Resin (HX-8080): 50 parts,

[0091] Solvent (DMF): 20 parts,

[0092] Solvent (butyl acetate): 40 parts,

[0093] Oil wax...

Embodiment 3

[0102] (a) Warp knitted fabric, lint-free, 0.8mm thick, 230g / m2 density 2 , made of ordinary wet bottom billet.

[0103] (b) roll coating foaming slurry, the formula of foaming slurry is calculated by mass:

[0104] Foaming resin (HX-8030): 100 parts,

[0105] Solvent (butanone): 35 parts,

[0106] Solvent (propylene glycol methyl ether): 35 parts,

[0107] Microsphere foaming powder (FN 100D): 5 parts,

[0108] Oil wax feel agent (LS-50-104): 2 parts,

[0109] Matting agent (TS-100): 0.7 parts,

[0110] BLPP509: 1.5 parts,

[0111] BLPP293: 1.5 parts,

[0112] BLPP102: 2 parts,

[0113] The coating weight is 500g / m 2 .

[0114] (c) drying at a temperature of 90°C.

[0115] (d) printing oily wax feeling slurry, the formula of oily waxy feeling slurry is calculated by mass:

[0116] Resin (HT-2280): 100 parts,

[0117] Solvent (propylene glycol methyl ether): 30 parts,

[0118] Solvent (ethyl acetate): 40 parts,

[0119] Oil wax feel agent (LS-50-104): 7 parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com