Self-modeling and self-heat preservation building

A self-insulation and building technology, applied in building construction, insulation, construction, etc., can solve the problems of long construction period, separate construction of insulation layer, large amount of manpower and material resources for installing and disassembling formwork, etc., to speed up construction progress and reduce construction. effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

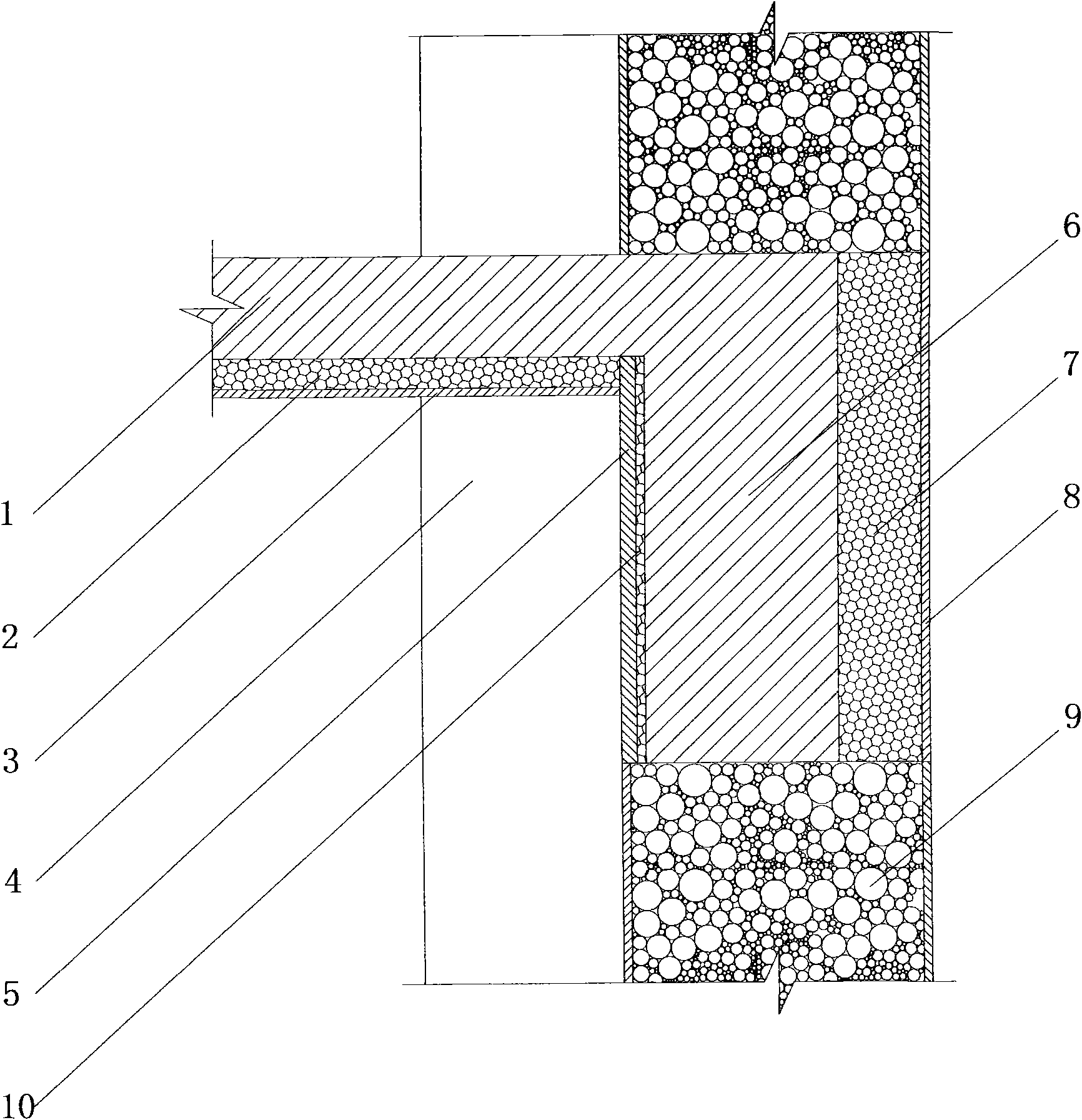

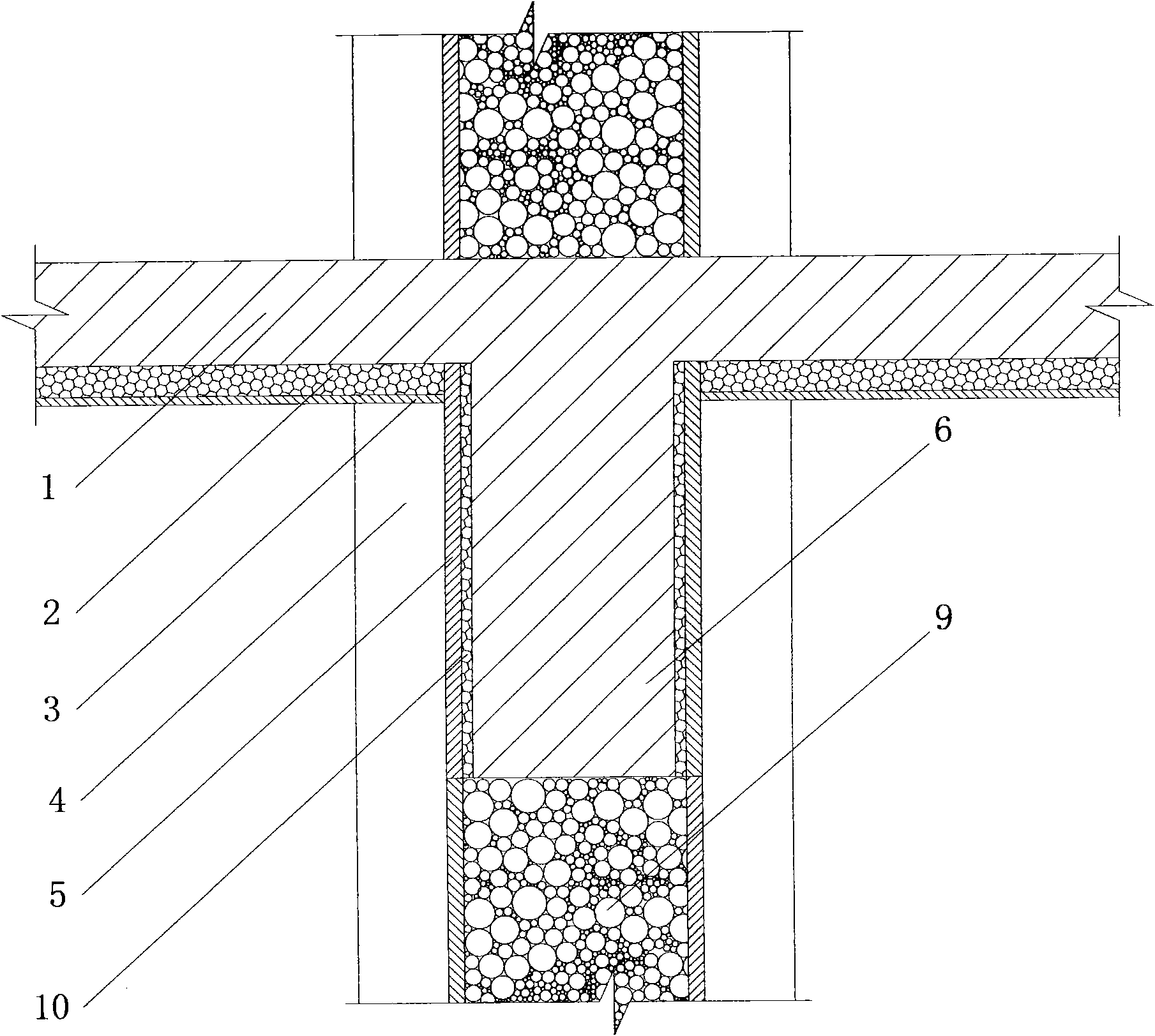

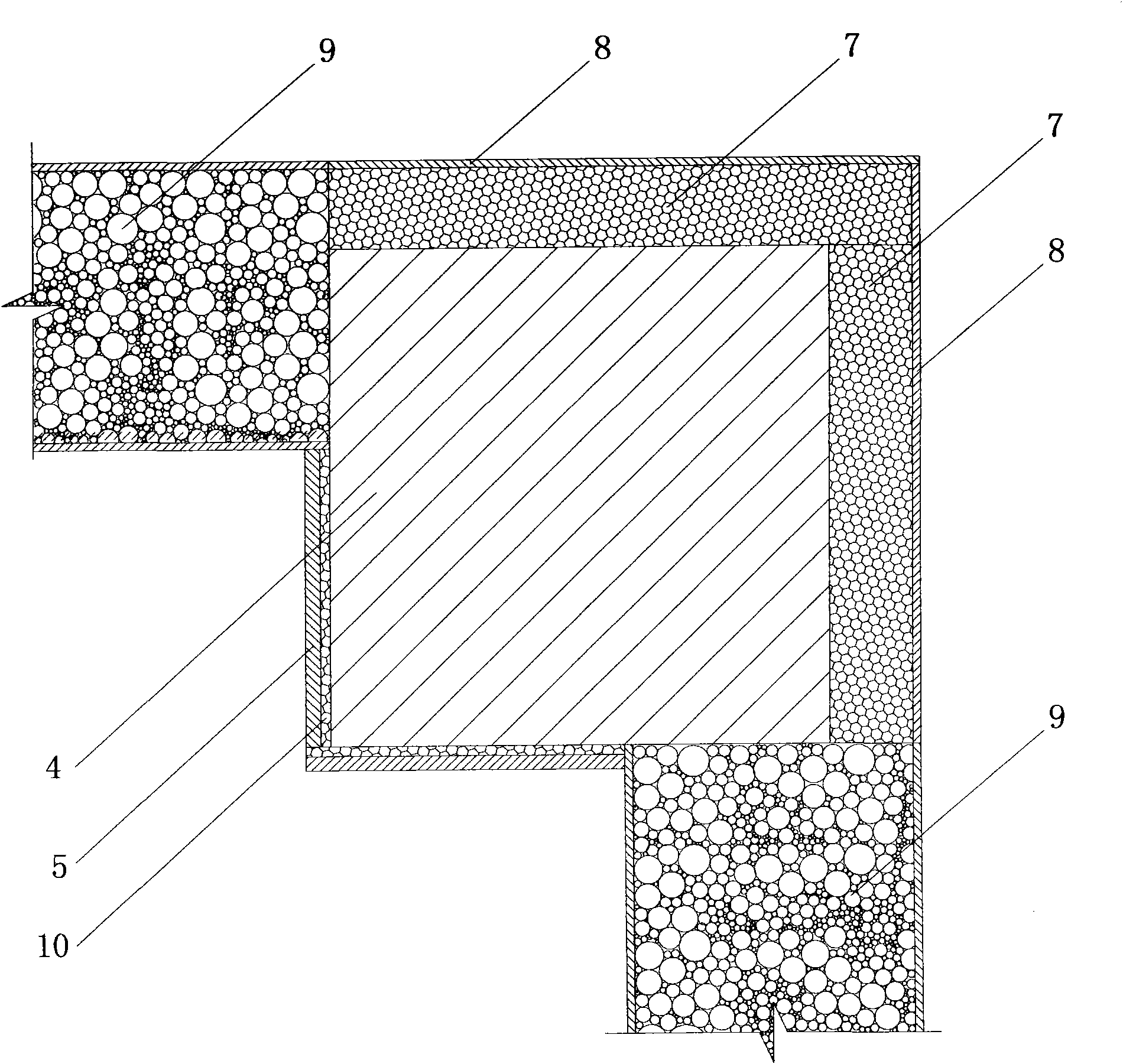

[0014] figure 1 It is the node section diagram of the exterior wall beam, the beam pouring trough is composed of the upper surface of the self-insulating wall panel 9, the beam formwork 5 with the insulation layer 10, and the formwork 8 with the insulation layer 7, and the concrete is poured into the reinforced concrete. The beam 6; the floor formwork 3 with the insulation layer 2 and the beam formwork 5 form the floor formwork, and the reinforced concrete is put into the floor slab 1; the beam formwork with the insulation layer 7 blocks the cold bridge at the beam position, with The beam template 5 of the insulation layer 10 blocks the local cold bridge at the interface between the wall panel and the beam; the self-insulation wall panel 9, the insulation layer 7 and the insulation layer 10 form a self-insulation system; the floor insulation layer 2 realizes the insulation of the upper and lower floors; The floor formwork 3 with the insulation layer 2, the beam formwork 5 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com