Vibration isolation device for seismic resistance of building

A building and vibration isolation technology, which is applied to building components, earthquake resistance, etc., can solve problems such as complex manufacturing, short service life of rubber blocks, and small vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

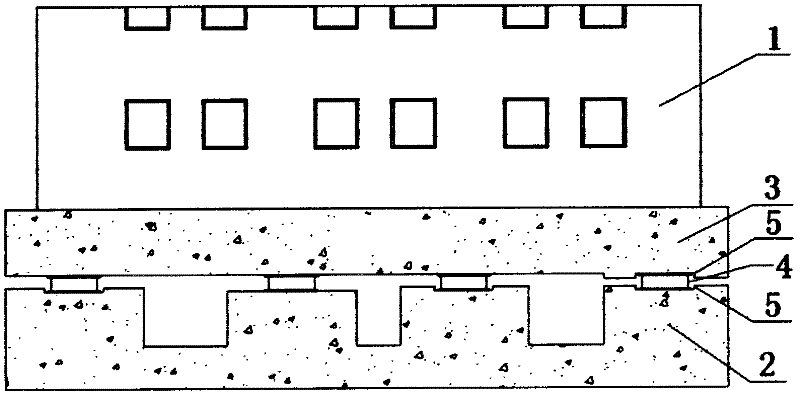

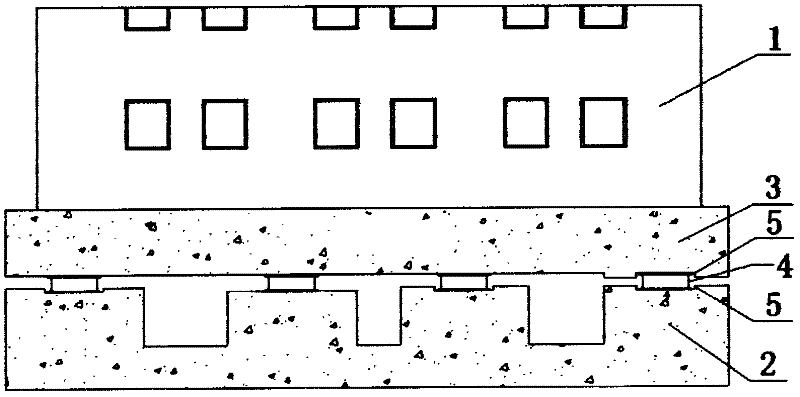

[0017] Such as figure 1 As shown, the vibration isolation device for building anti-seismic is arranged between the building main body 1 and the foundation support 2, wherein the vibration isolation device includes an equal-thickness plate arranged under the building main body 1 The vibration isolation layer 3 and the vibration isolation pad 4 arranged between the equal thickness plate vibration isolation layer 3 and the foundation support 2 . In this design, the original upper pier, beam, and slab structures are replaced by an equal-thickness plate isolation layer. Objectively form the termination position of the upper structure, that is, the embedded end of the structure. The structural calculation model is clear and reasonable, which relieves a major constraint in the design of earthquake-isolated buildings. It is of great significance to the layout, adjustment and optimization of the structure below the earthquake-isolation pad. It is especially suitable for low-rise struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com