Swinging buckling restrained brace and frame structure system and construction method thereof

A technology of anti-buckling support and frame structure, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of difficult guarantee of safety, strong compressive capacity, weak tensile capacity, etc., and achieve good energy consumption and shock absorption effect, The effect of high structural rigidity and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

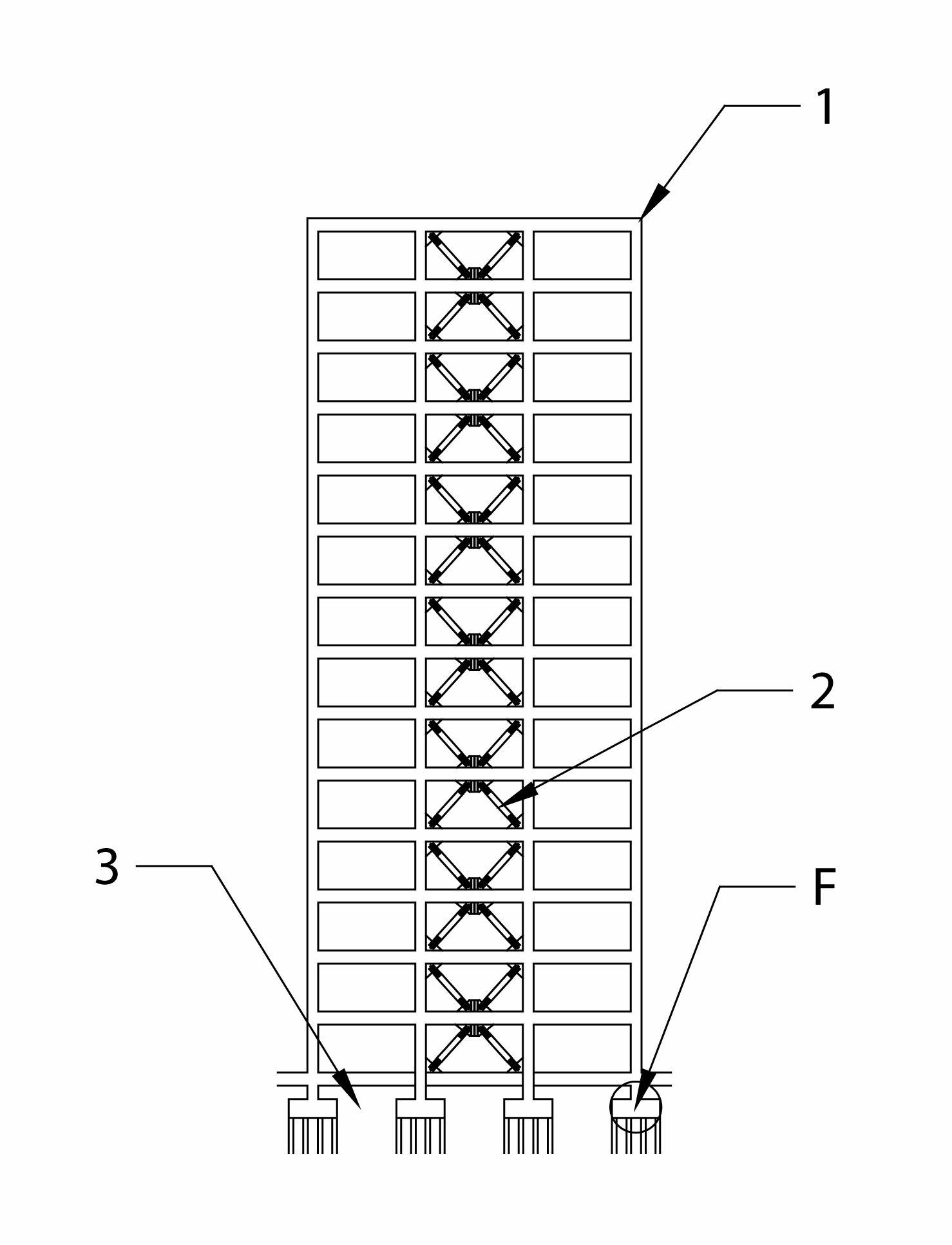

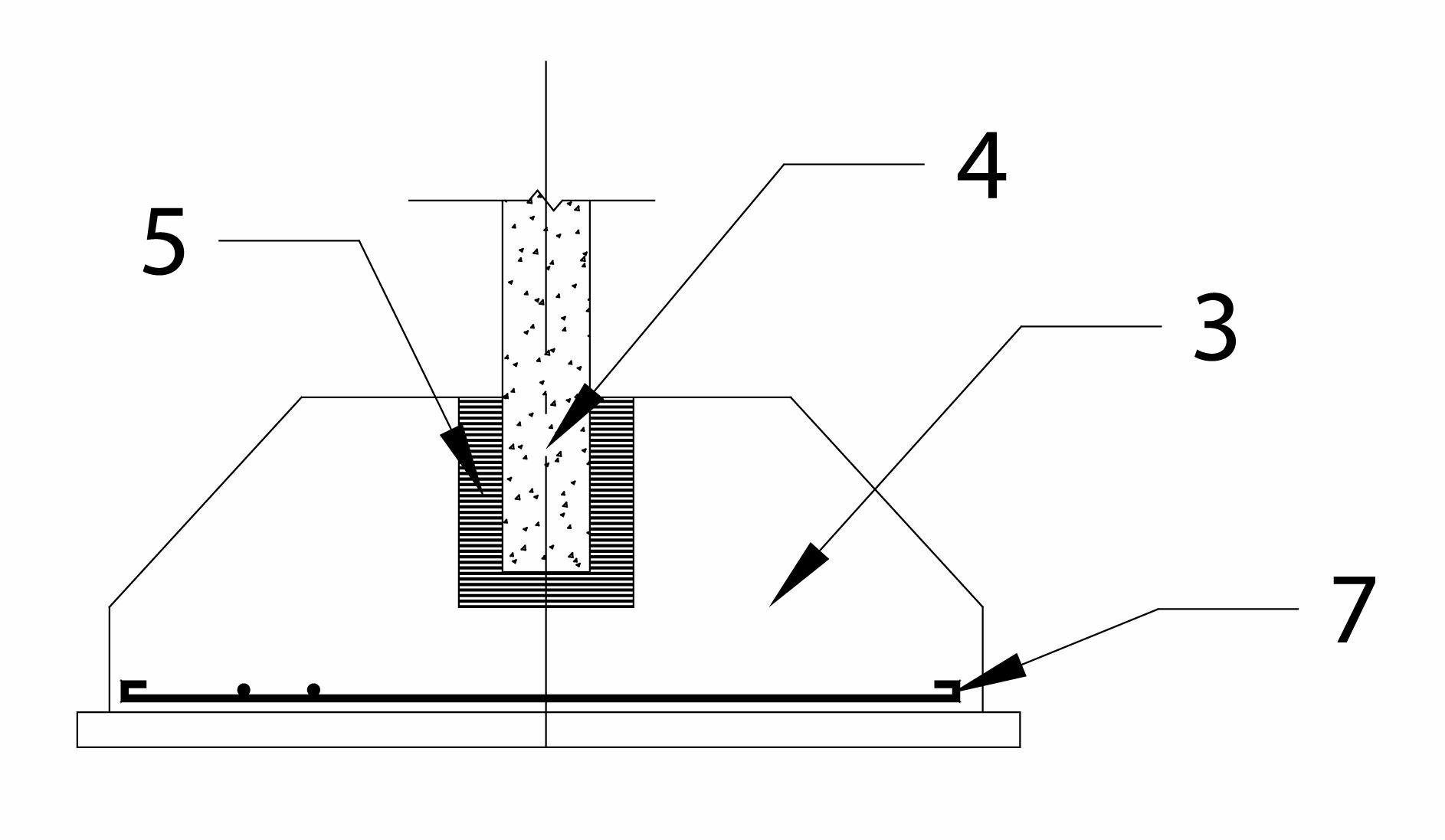

[0037] Example 1: The present invention is used in a reinforced concrete structure. The frame 1 is a reinforced concrete frame. The anti-buckling support 2 is installed between the frame column 4 and the frame beam 6 in the middle span of the rigid concrete frame. 2 The special structure avoids the problem of buckling of the reinforced concrete frame in the center. It can yield without buckling under tension and compression, which can better consume the seismic energy input to the structure. The connection between the bottom end of the frame column 4 of the reinforced concrete frame without the anti-buckling support 2 and the foundation 3 adopts the fixed end F, and the connection between the bottom end of the frame column 4 of the reinforced concrete frame with the anti-buckling support 2 and the foundation 3 adopts Embedded end M. Pre-embedded parts are provided on the bottom and surrounding surfaces of the frame column 4 of the reinforced concrete frame with the anti-bucklin...

Embodiment 2

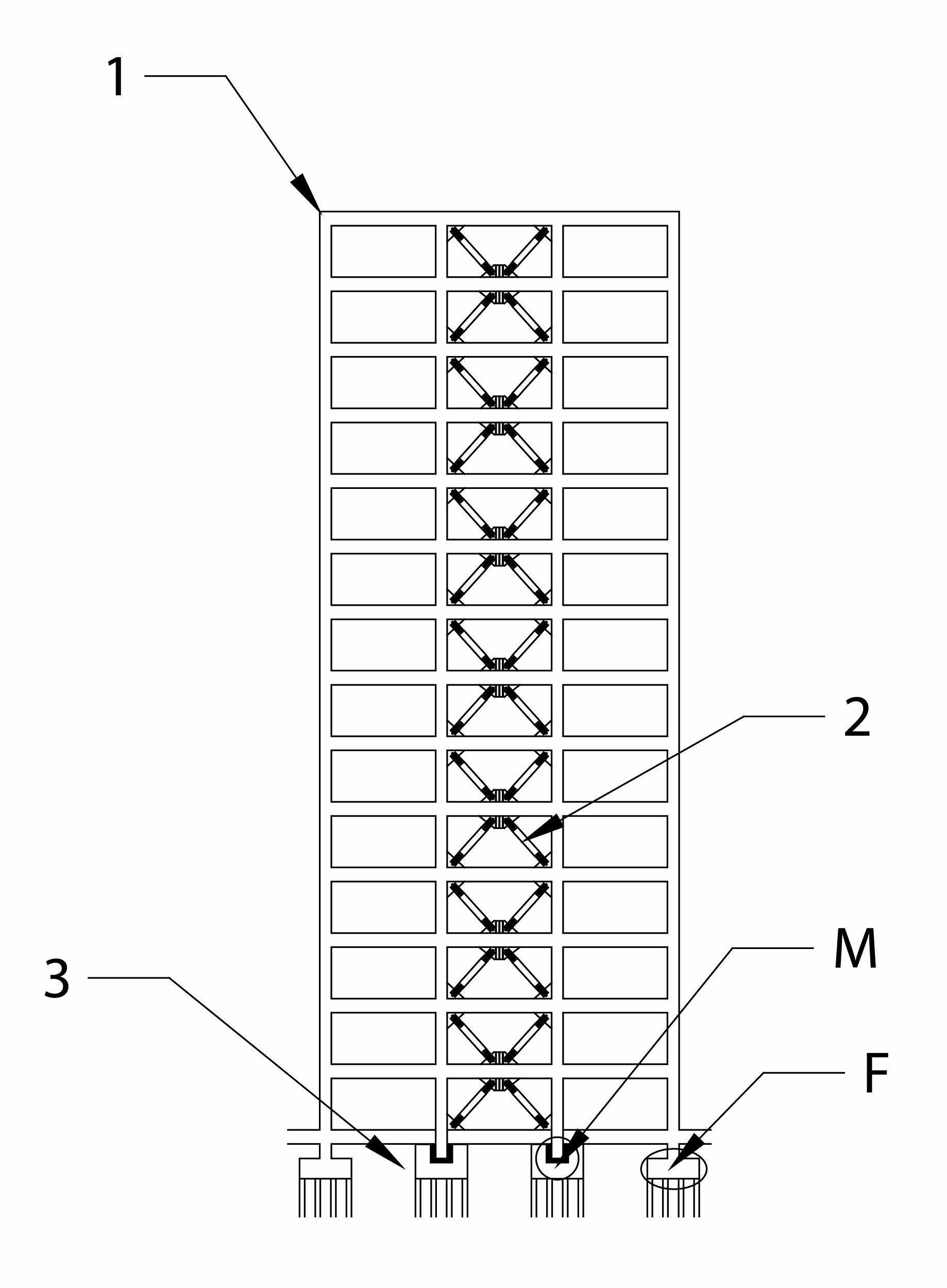

[0038] Embodiment 2: The present invention is used in a steel structure. The frame 1 is a steel frame. An anti-buckling support 2 is installed in the middle of the steel frame. The special structure of the anti-buckling support 2 prevents the central steel frame from buckling under compression. The problem is that it can yield without buckling under tension and compression, which can better consume the seismic energy input to the structure. The bottom end of the frame column 4 of the rigid frame without the anti-buckling support 2 is connected to the foundation 3 by a fixed end F, and the bottom end of the frame column 4 of the rigid frame with the anti-buckling support 4 is connected with the foundation 3 by embedded fixing End M. Embedded parts are provided on the foundation 3 contacting the bottom end of the frame column 4 of the rigid frame on which the anti-buckling support 2 is installed. The rigid frame with the anti-buckling support 2 is connected to the embedded parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com