Diesel engine for vehicle and control method thereof

A diesel engine and engine technology, applied in engine control, engine components, combustion engines, etc., can solve the problems of low compression end temperature, difficult to establish self-ignition conditions, and low ignition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

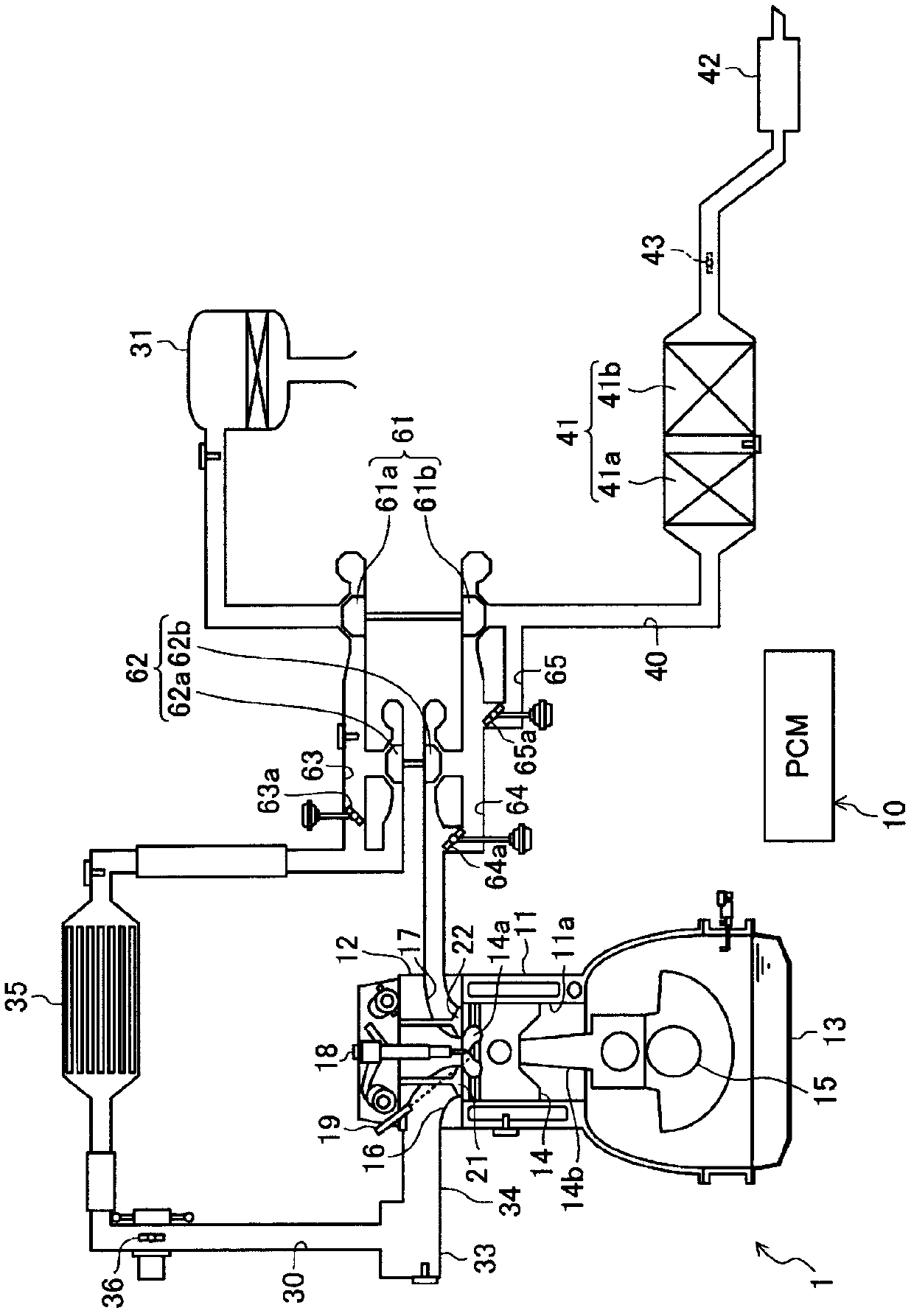

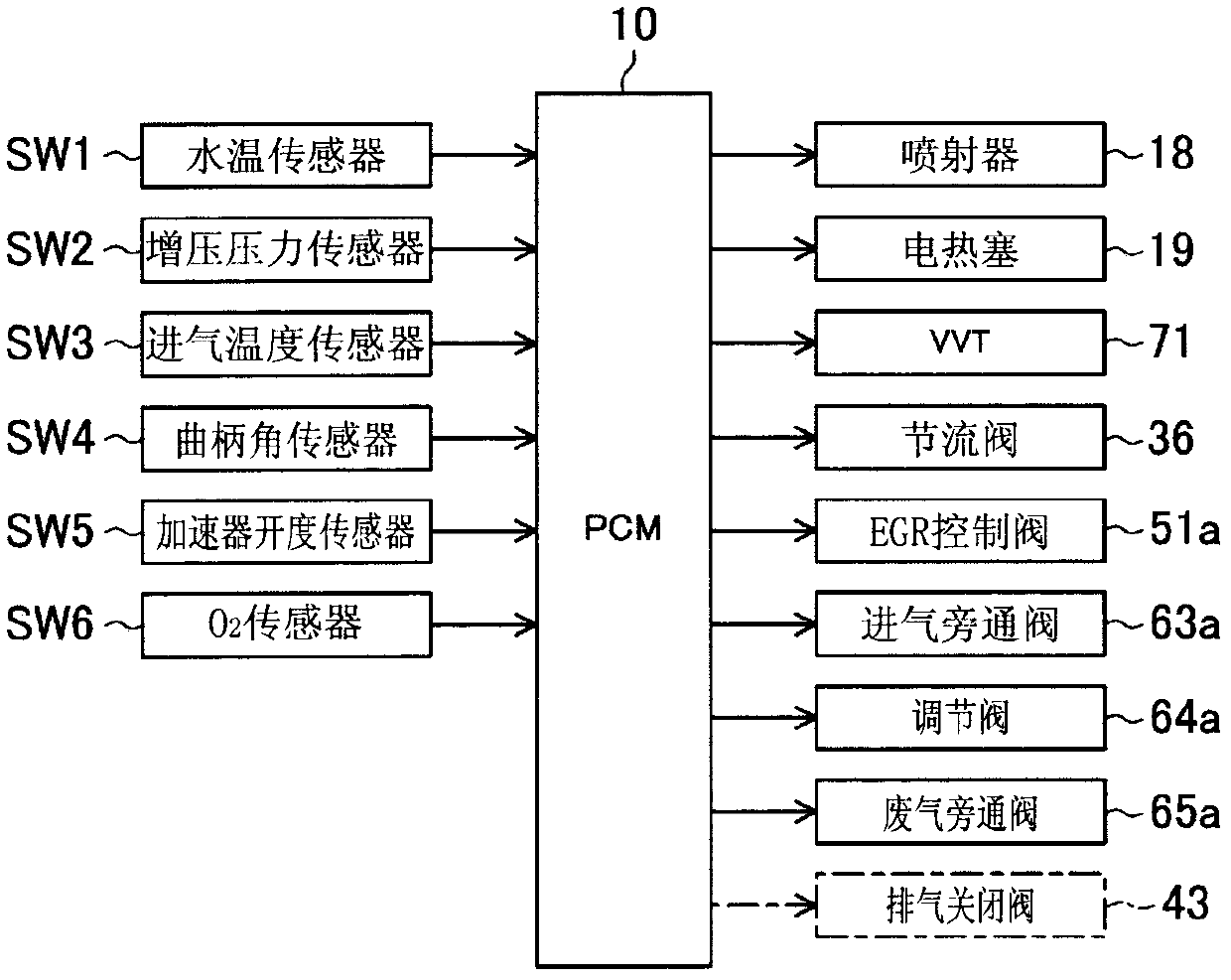

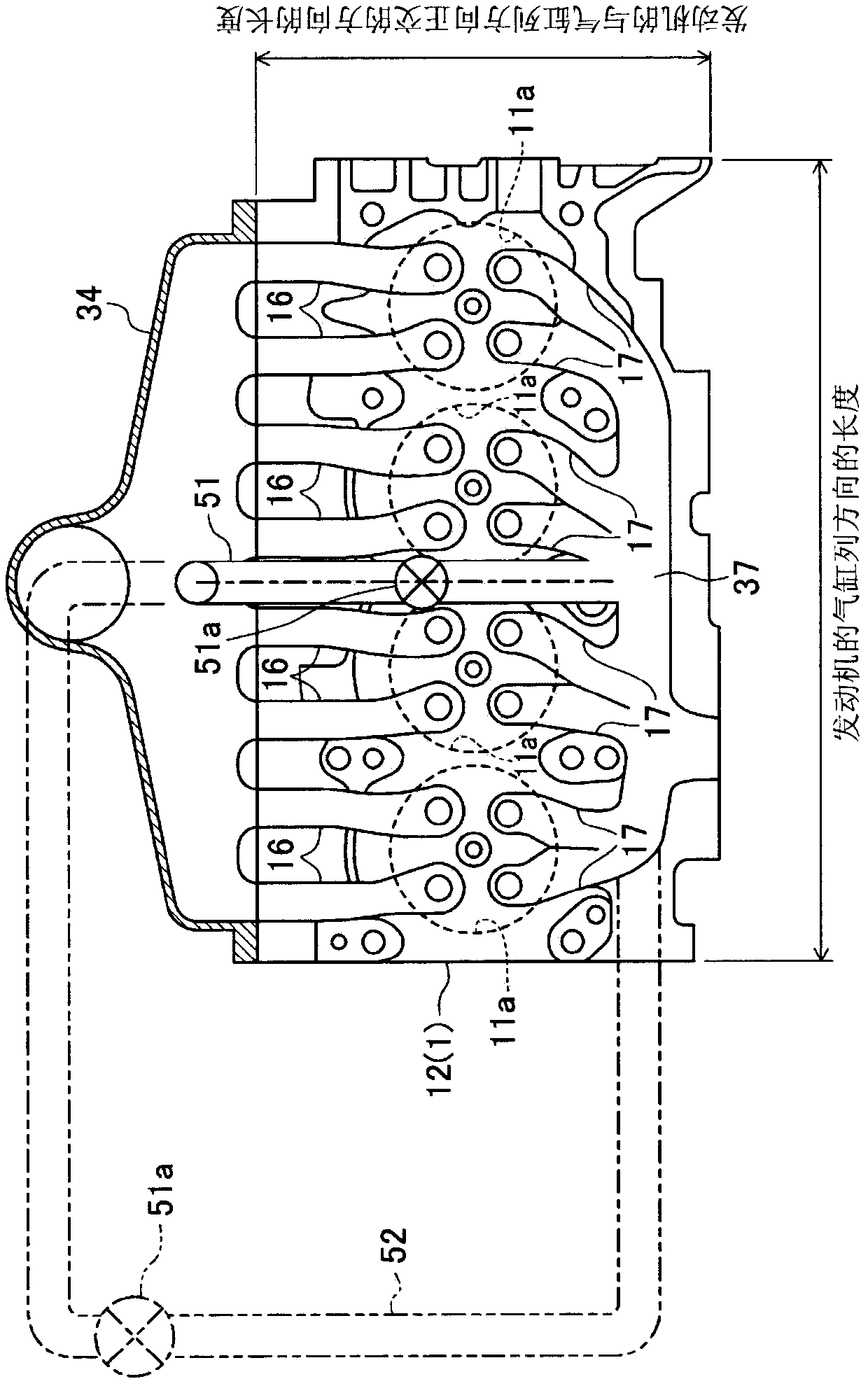

[0062] Hereinafter, the diesel engine according to Embodiment 1 of the present invention will be described based on the drawings. In addition, the nature of the description of the following specific embodiments is merely an illustration. figure 1 , 2 A schematic configuration of the engine 1 according to the embodiment is shown. The engine 1 (engine main body) is a diesel engine mounted on a vehicle and supplied with fuel mainly composed of light oil, and has a plurality of cylinders 11a ( figure 1 Only one cylinder block 11 is shown in , a cylinder head 12 provided on the cylinder block 11 , and an oil pan 13 provided on the lower side of the cylinder block 11 and stores lubricating oil. Engine 1 in this example as image 3Shown is an inline four-cylinder engine in which the first to fourth four cylinders 11 a are arranged in a row, but it is not limited to such an inline four cylinder engine. Pistons 14 are reciprocally inserted in the respective cylinders 11a of the eng...

Embodiment approach 2

[0107]In Embodiment 1, the required EGR rate is achieved by introducing the burned gas into the cylinder 11a through the EGR passages 51 and 53 to ensure its ignitability. EGR rate to ensure ignition. Various methods can be employed in realizing the internal EGR, but here the internal EGR is realized by early closing of the exhaust valve 22 . That is, a negative overlap period in which both the intake valve 21 and the exhaust valve 22 are closed is provided in the exhaust stroke and the intake stroke, so that the burned gas remains in the cylinder 11a.

[0108] In this Embodiment 2, between the exhaust purification device 41 and the muffler 42 on the exhaust passage 40, a figure 1 and figure 2 The exhaust closing valve 43 (exhaust throttle valve) phantomly shown in FIG. The opening of the exhaust shutoff valve 43 is controlled by the PCM 10, and it is usually opened. However, as will be described later, in this example, the exhaust shutoff valve 43 may sometimes be under a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com