Gas engine using low calorie gas fuel

A low calorific value gas, gas engine technology, applied in combustion engines, internal combustion piston engines, gaseous engine fuels, etc., can solve problems such as inability to be directly applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

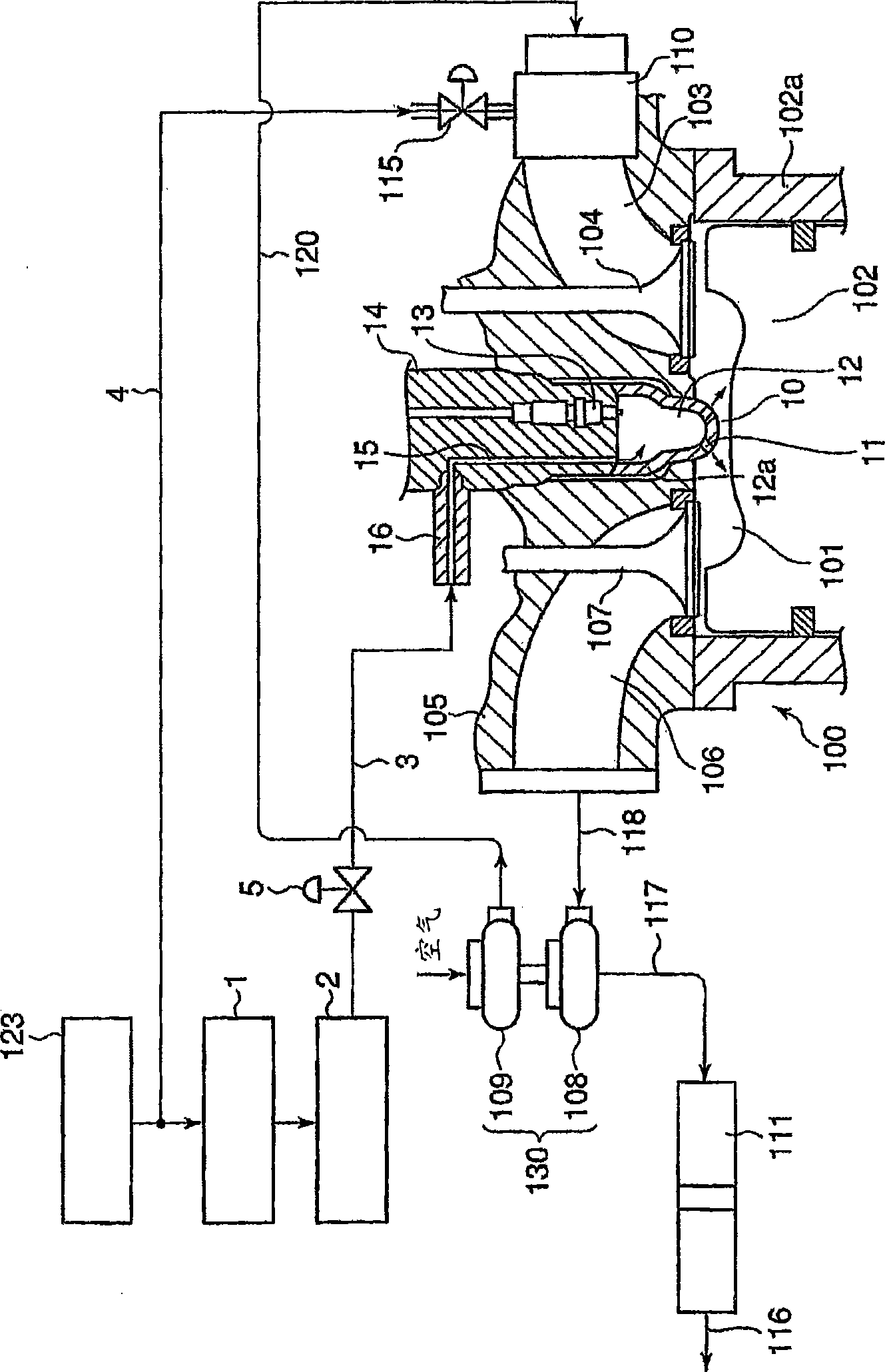

[0052] figure 1 It is a block diagram showing a structure around a combustion chamber of a gas engine using low calorific value gas as fuel according to the first embodiment of the present invention.

[0053] The fuel gas uses coal mine methane and other methane concentrations as low as 50% or less, and the calorific value is only about 30% of the low calorific value gas (refer to Figure 4 ), the low calorific value gas is stored in the low calorific value gas supply source 123.

[0054] The outlet of the low calorific value gas supply source 123 is connected to the PSA processing device 1 .

[0055] In this PSA treatment device 1, implement pressure swing adsorption type treatment (PSA treatment), that is, the low calorific value gas that calorific value has only about 30% of conventional calorific value gas (referring to Figure 4 ) is pressurized and made to flow through an adsorbent such as zeolite, and impurities are separated by adsorption to obtain methane gas with ...

no. 2 approach

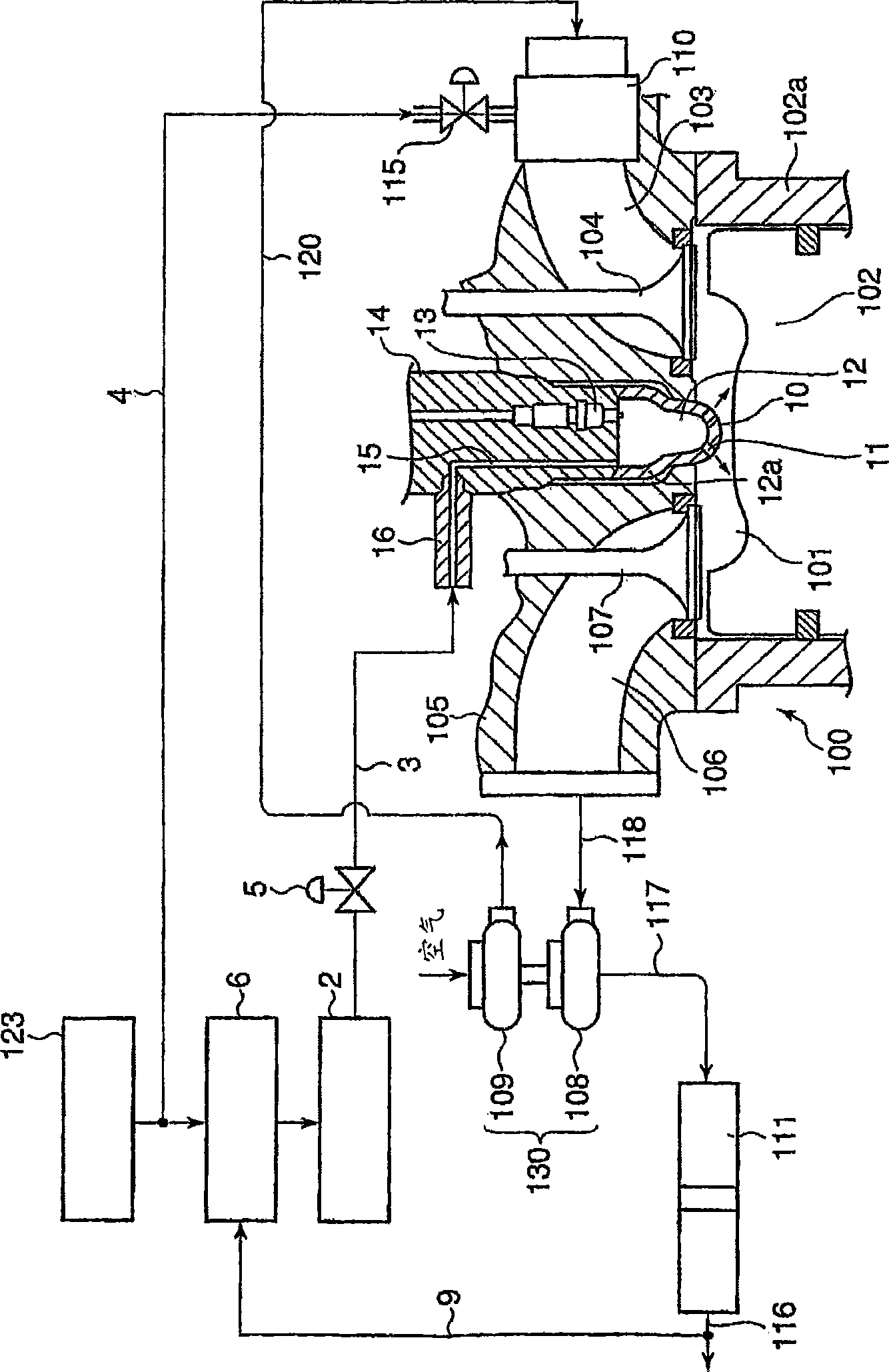

[0078] figure 2 It is a block diagram showing a structure around a combustion chamber of a gas engine using a low calorific value gas as fuel according to a second embodiment of the present invention.

[0079] In this second embodiment, the PSA treatment device 1 in the first embodiment is replaced with a temperature swing adsorption treatment device (TSA treatment device) 6 .

[0080] That is, in the second embodiment, the low calorific value gas from the low calorific value gas supply source 123 is sent to the TSA processing apparatus 6 .

[0081] That is, in this TSA treatment device 6, as mentioned above, implement the temperature swing adsorption type treatment (TSA treatment), that is, the calorific value is only about 30% of the conventional calorific value gas (refer to Figure 4 ), through adsorption and separation of impurities at a temperature increase of about 200°C to obtain methane gas with a concentration of 100%. In addition, since the detailed operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com