A device and method for synchronously producing methane-enriched synthesis gas and light coal tar

A coal tar and synthesis gas technology, applied in separation methods, methane capture, chemical instruments and methods, etc., can solve the problems of high heavy components, low content of BTX and PCX components, semi-coke production, etc., to reduce Scale and investment, the effect of enhancing economic competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

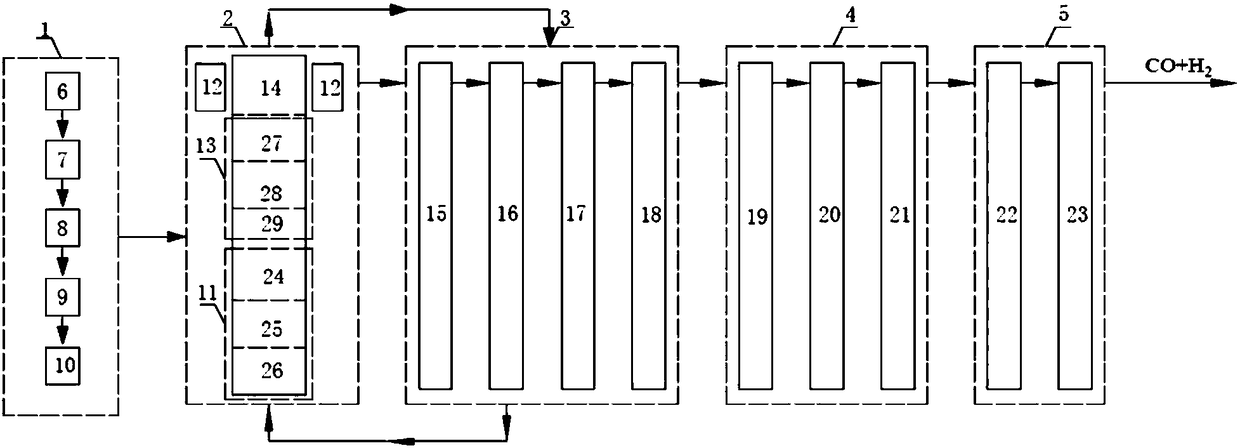

[0032] In order to make the technical solutions and advantages of the present invention clearer, the device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] see figure 1 , the present invention includes a carbonaceous material rapid pyrolysis reaction system 2 and a continuous pressurized steady-state feed system 1 connected to its inlet, a synthesis gas purification and particle distribution system 3 connected to its outlet, and a synthesis gas purification and particle distribution system 3. The outlet is connected to the light coal tar recovery system 4 and the methane enrichment and separation system 5 in sequence;

[0034] The carbon-containing material rapid pyrolysis reaction system 2 includes a circulating particle secondary cracking hydrogen production subsystem 11, a rapid mixing and heating subsystem 13, and a carbon-containing material constant temperature-pressuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com