Diesel engine and method of controlling the diesel engine

A diesel engine and engine technology, applied in engine control, engine incandescent ignition, engine ignition, etc., can solve problems such as low temperature and pressure, prolonged ignition delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

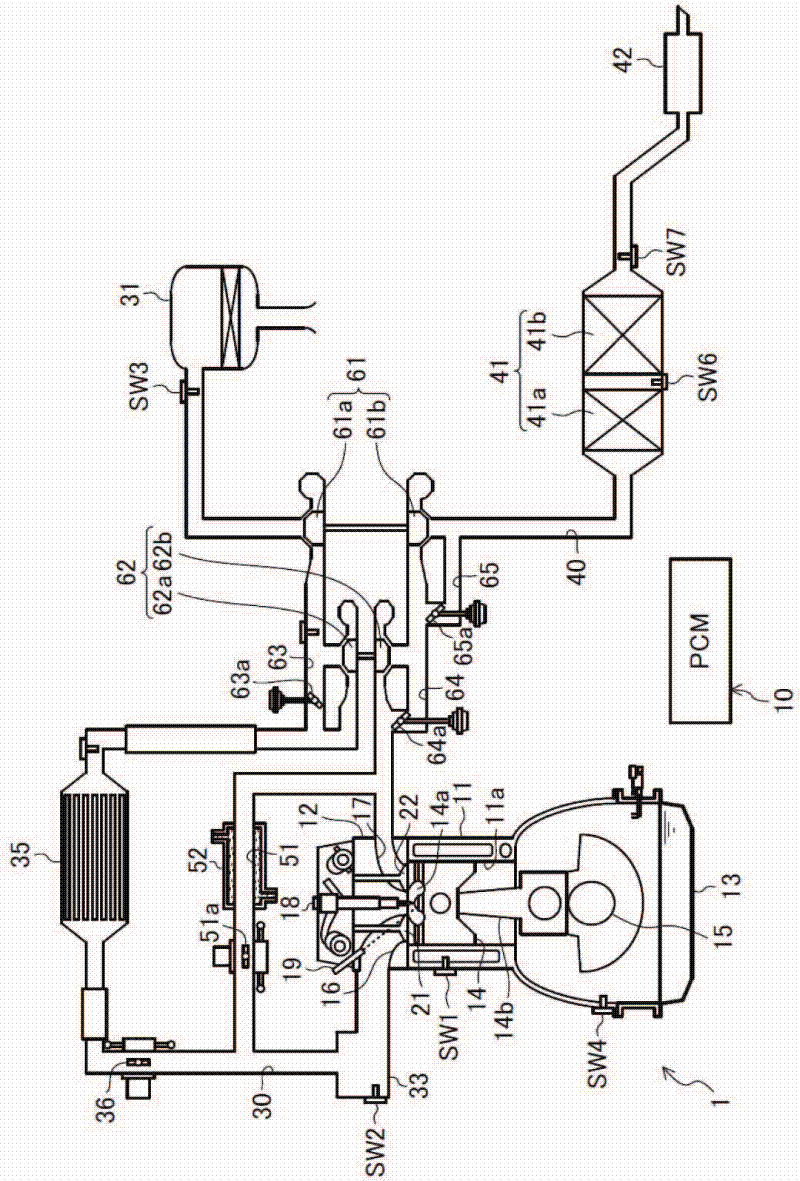

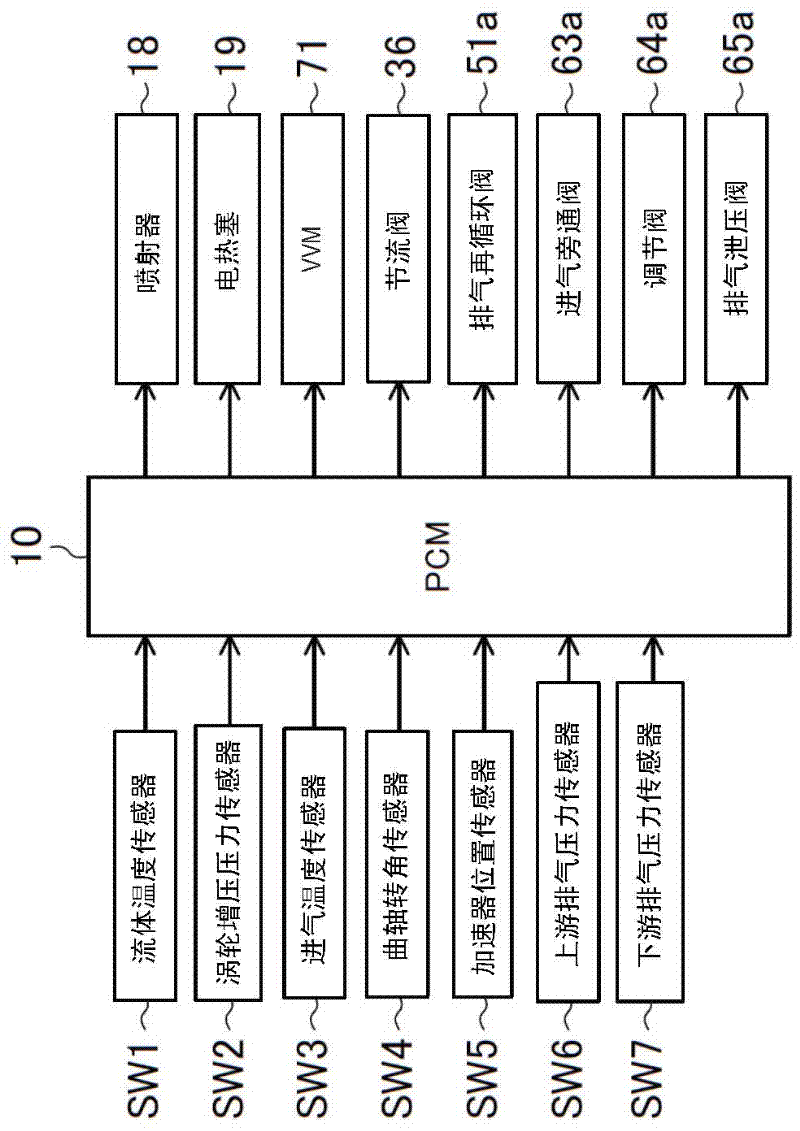

[0037] The following reference drawings are described in detail according to the diesel engine of the embodiment of the present invention.It should be noted that the description of the following preferred embodiments is only an example. figure 1 and 2 Show the schematic structure of the engine (engine body) 1 of the embodiment.Engine 1 is a diesel engine that is installed to the vehicle and provides fuel with the main component of diesel fuel.The diesel engine includes a cylinder body 11 with multiple cylinder 11A (only one cylinder), the cylinder head 12 set on the cylinder body 11, and the oil bottom of the oil bottom of the cylinder body 11 and store lubricating oil in it and store lubricating oil.Shell 13.In the cylinder 11A of the engine 1, the piston 14 is installed in a reciprocating way, and part of the cavity of the shrinkage burning chamber 14A is formed on the top surface of each piston 14.Each piston 14 is connected to the crankshaft 15 by connecting rod 14B.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com