Control method and control system for runaway of diesel engine

A control method and control system technology, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as broken shaft, exhaust sound tightness, and connecting rod bolt breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

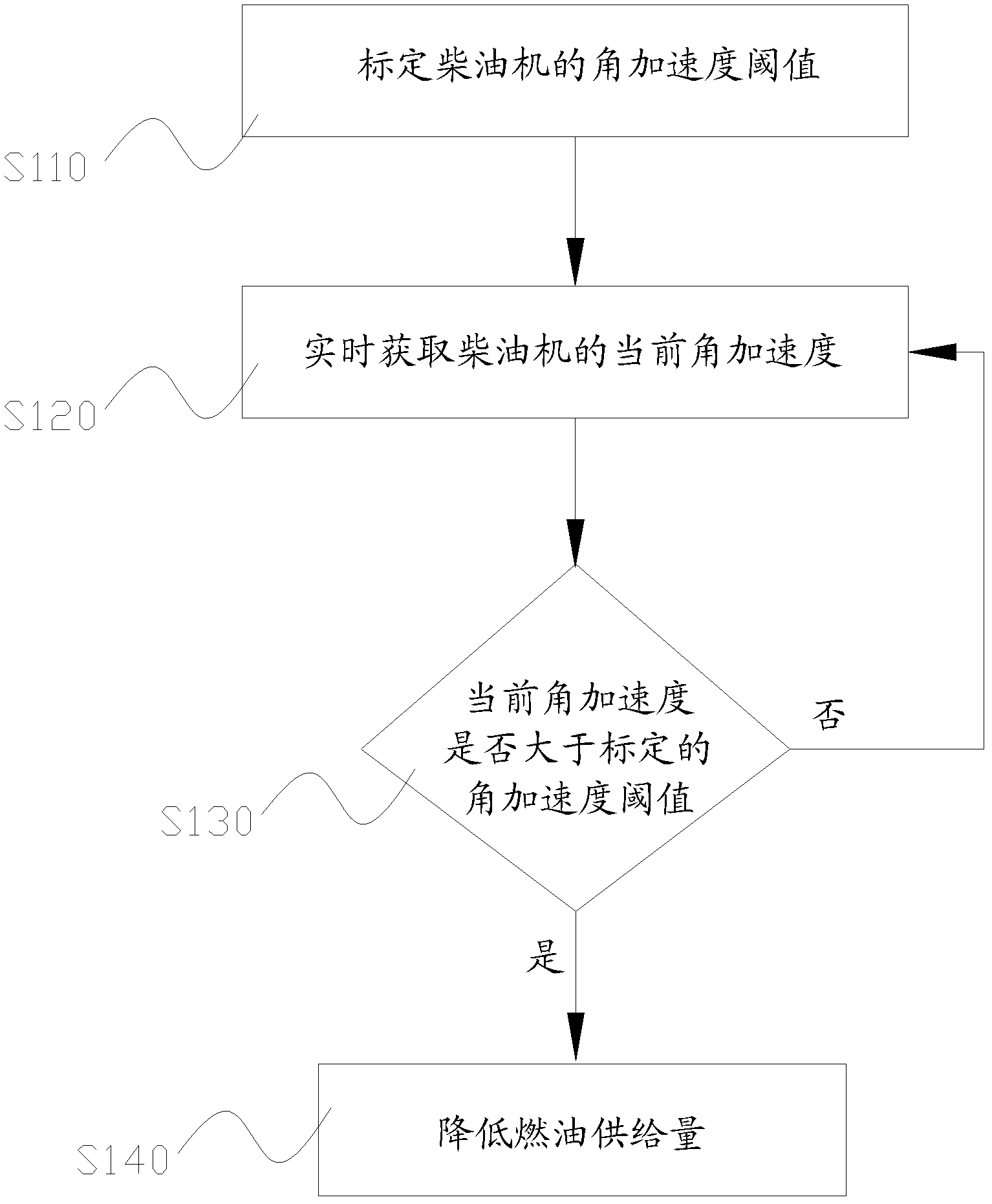

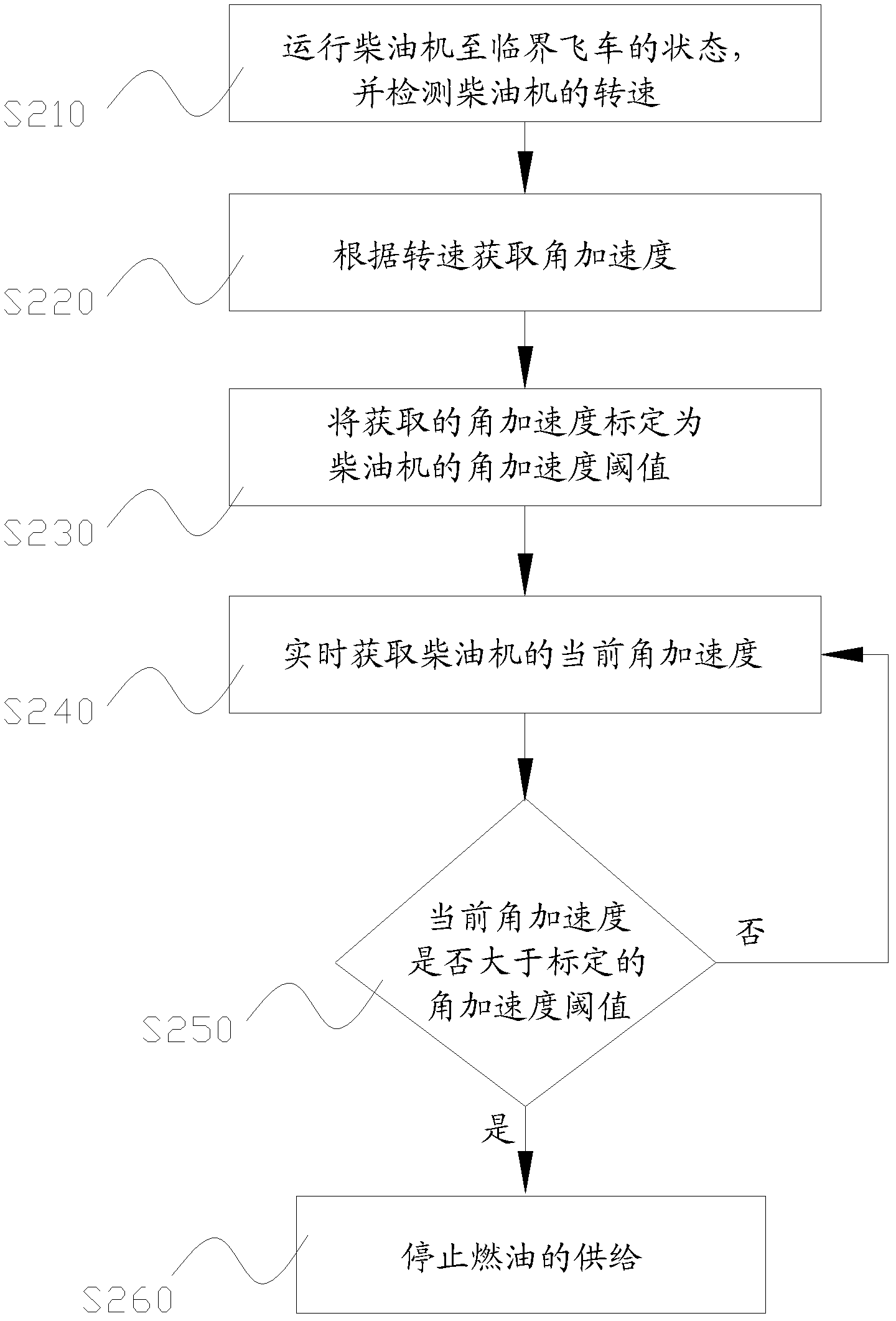

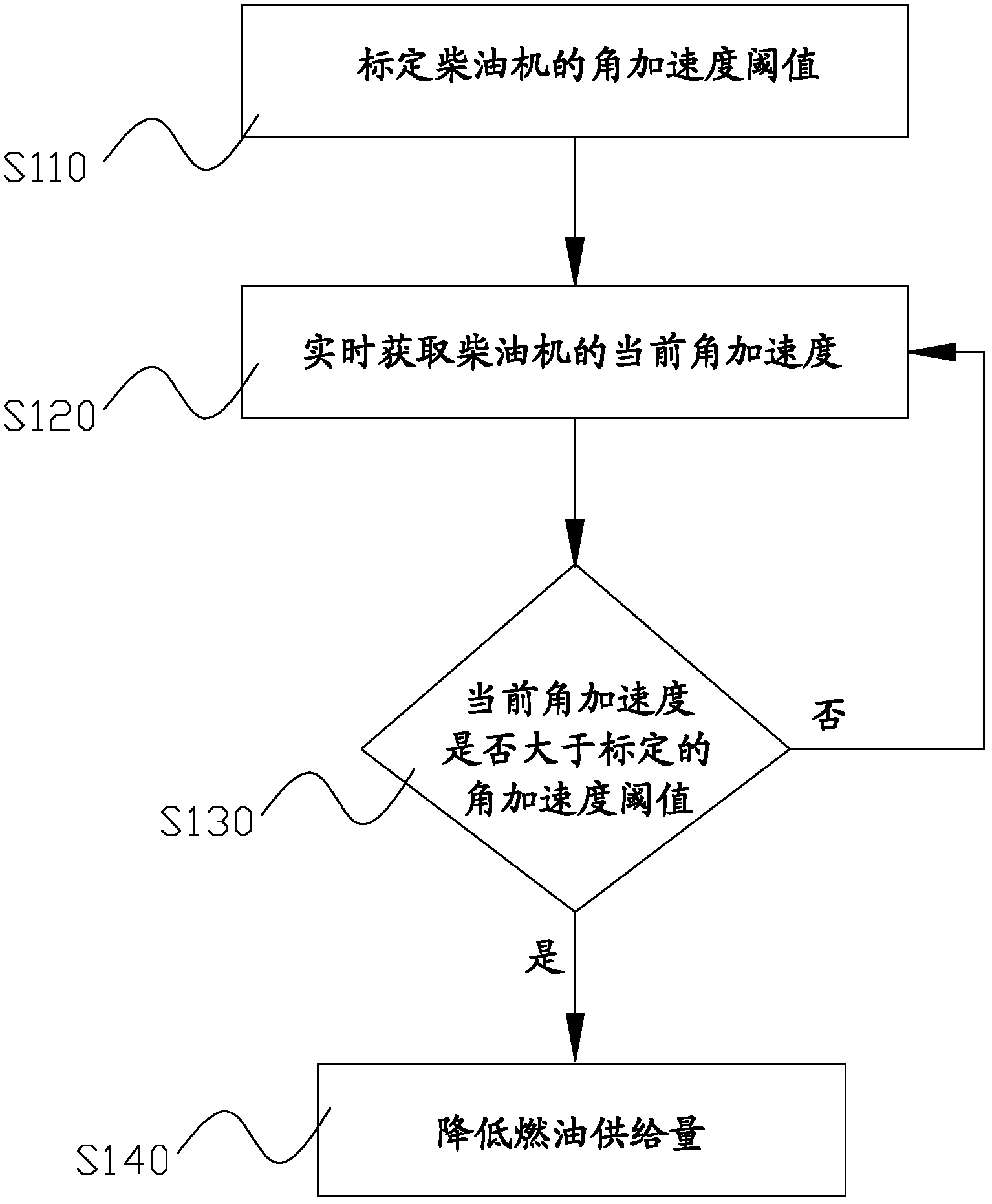

[0024] This specific implementation includes the following steps:

[0025] S210) Run the diesel engine to a critical speed, and detect the speed of the diesel engine;

[0026] S220) Obtain the angular acceleration according to the rotational speed;

[0027] S230) Calibrating the acquired angular acceleration as the angular acceleration threshold of the diesel engine;

[0028] The above steps can be carried out before the diesel engine is used or shipped. For example, before the diesel engine leaves the factory, the diesel engine can be run to the critical runaway state through the bench test control system of the diesel engine, and the angular acceleration of the diesel engine in the process can be obtained for calibration before leaving the factory. In addition, the angular acceleration may change from the start of the diesel engine to the critical speed. The detection device can be used to detect the speed of the diesel engine in the process in real time. The calibration unit calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com