Automatic surge testing method for turbine compressor

A turbo-compressor, automatic testing technology, applied in machine/engine, mechanical equipment, pump control, etc., can solve the problems of lack of timeliness and high labor costs, achieve long-term safe and stable operation, save labor costs, avoid errors and single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

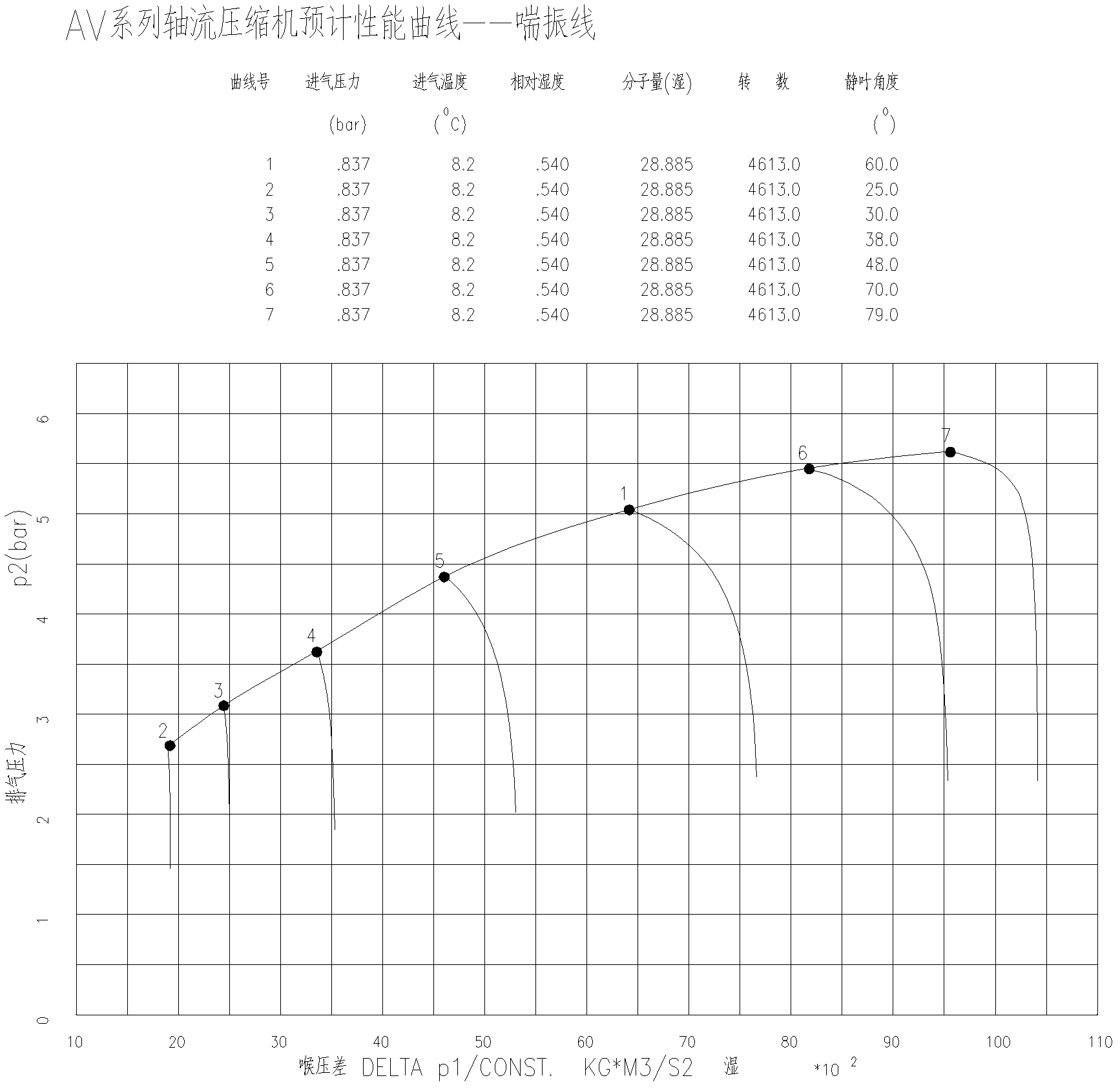

[0060] see Figure 6 to Figure 11 , the inventor uses the following application cases to further explain the method of the present invention. In this embodiment, the turbo compressor is selected as the AV series axial flow compressor. First, programming is carried out according to the method steps of the present invention, and then the unit control system is used to automatically control the unit according to the program, and finally the anti-surge curve of the turbo-compressor is obtained.

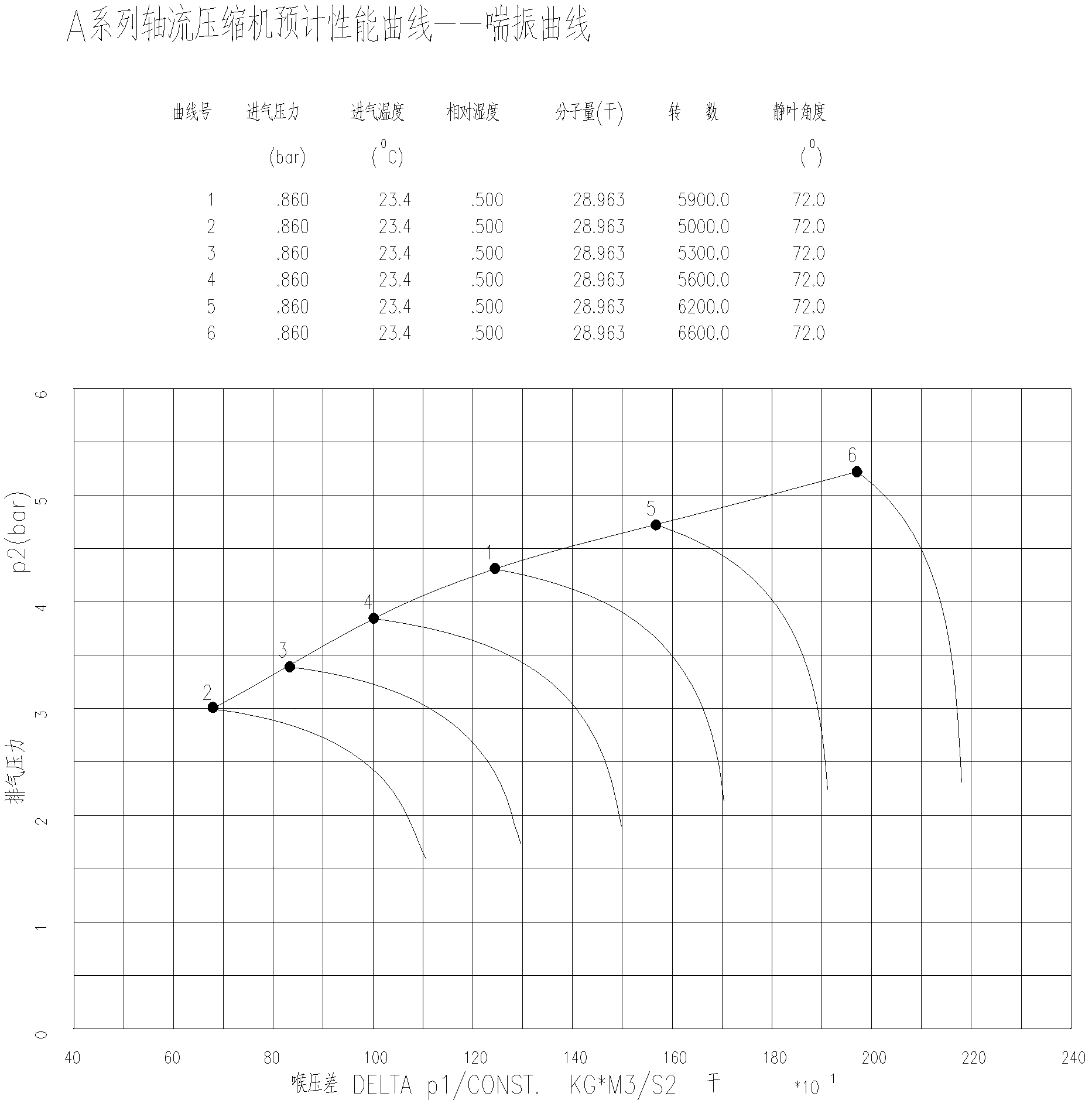

[0061] Such as Image 6 As shown, in this embodiment, four expected surge test points are selected from the surge curve obtained by the aerodynamic calculation of the axial flow compressor to be tested: (330, 25), (395, 30), (480, 38) and (575, 49), according to step 2) to step 8) of the present invention, respectively input and carry out actual testing to the 4 determined surge test points, the working condition parameters of each surge test point obtained are as follows Figure 7 to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com