Manufacturing process of metal bottle with air-tight seal

A production process and metal bottle technology, applied in the container discharge method, equipment loaded into the pressure container, gas/liquid distribution and storage, etc., can solve the problems affecting the safe operation and service life of the container, the increase in the weight of the gas cylinder, and the occupancy The problem of large space and other problems can be achieved to ensure the purity of the filling gas, improve stability, and achieve the effect of small shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

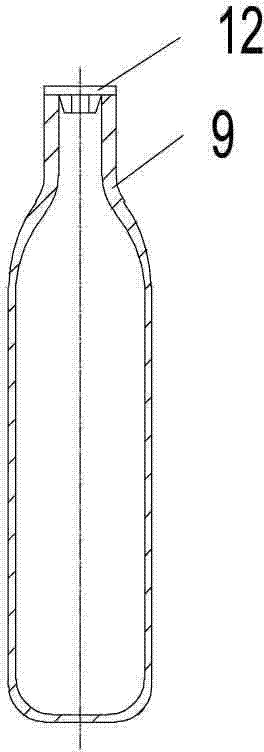

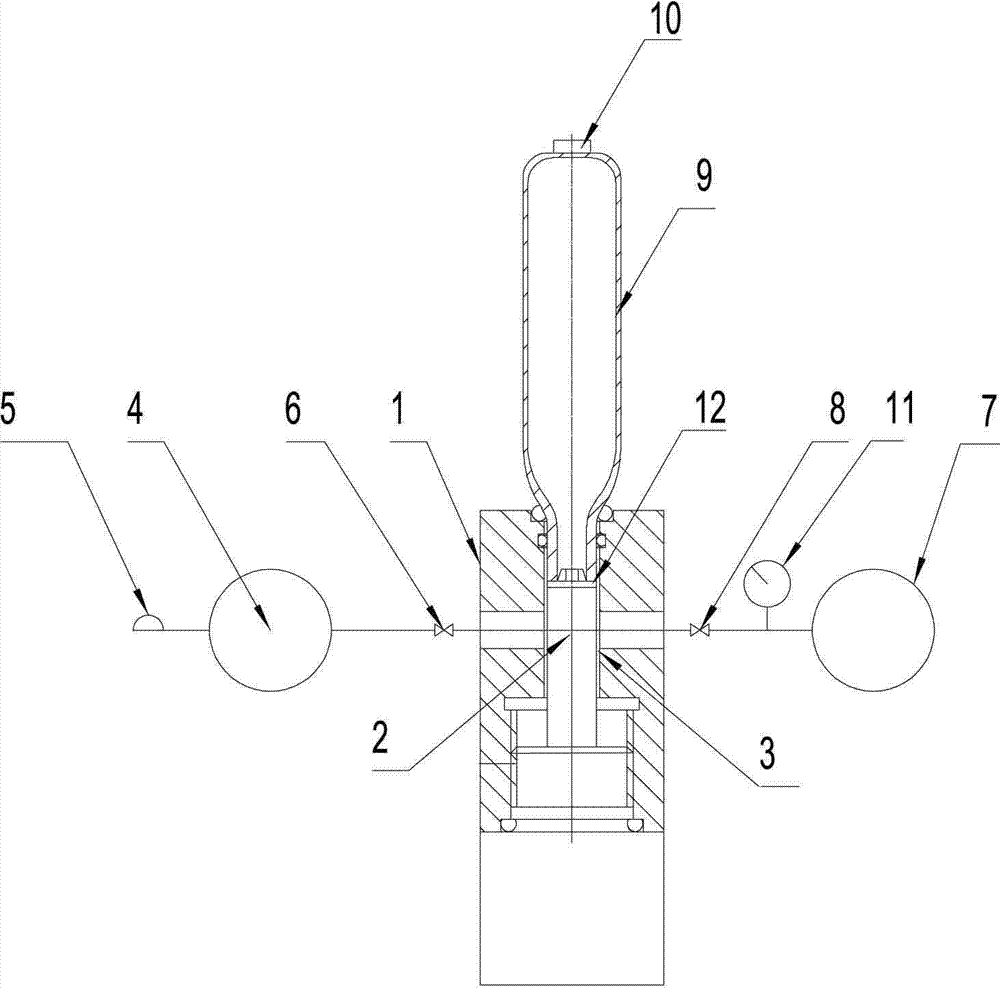

[0018] Such as figure 1 As shown, the structure of the metal bottle with airtightness is: the sealing sheet (12) and the bottle body (9) are integrated into one structure, and the bottle body is filled with gas.

[0019] The production process of a metal bottle with an airtight seal, the steps are as follows:

[0020] 1) Blanking: Use stainless steel plate as the metal bottle blank, cut into circles according to the process size, use 180 # The surface of the blank is ground without defects by the angle grinding film, reaching a roughness of ≤3.2, and the edges on both sides are smoothed without burrs;

[0021] 2) Annealing: the blank is put into a resistance furnace for annealing heat treatment, the annealing temperature is 900-1000°C, the temperature is kept for 0.5 hours, and the furnace is air-cooled;

[0022] 3) Deep drawing: 4-pass deep-drawing: the annealed blank is stamped and deep-drawn with a four-column hydraulic press to make a semi-finished cylindrical part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com