On-line detection vision positioning method for combination surface hole group of engine cylinder

A technology for engine cylinder block and visual positioning, which is applied to measuring devices, instruments, and optical devices, etc. It can solve the problems of inconvenient loading of engine block, damage of positioning pins, failure to realize the unification of positioning reference and measurement reference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

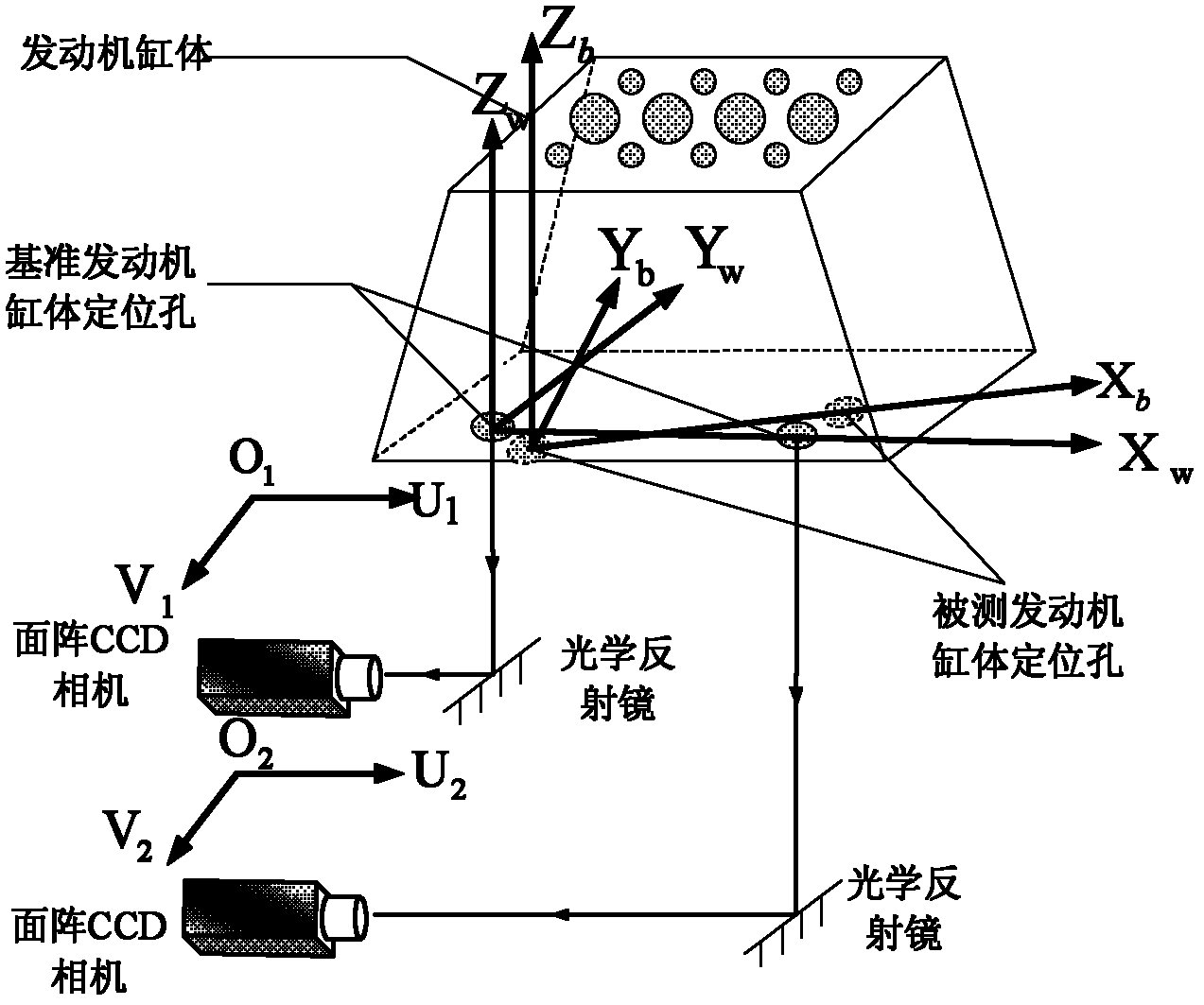

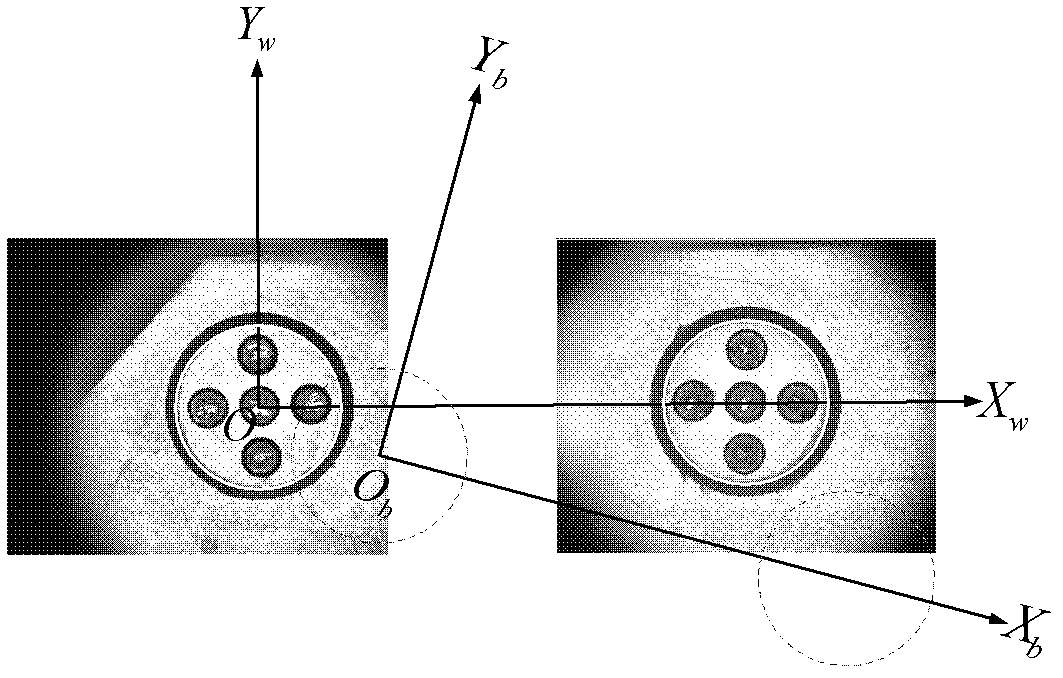

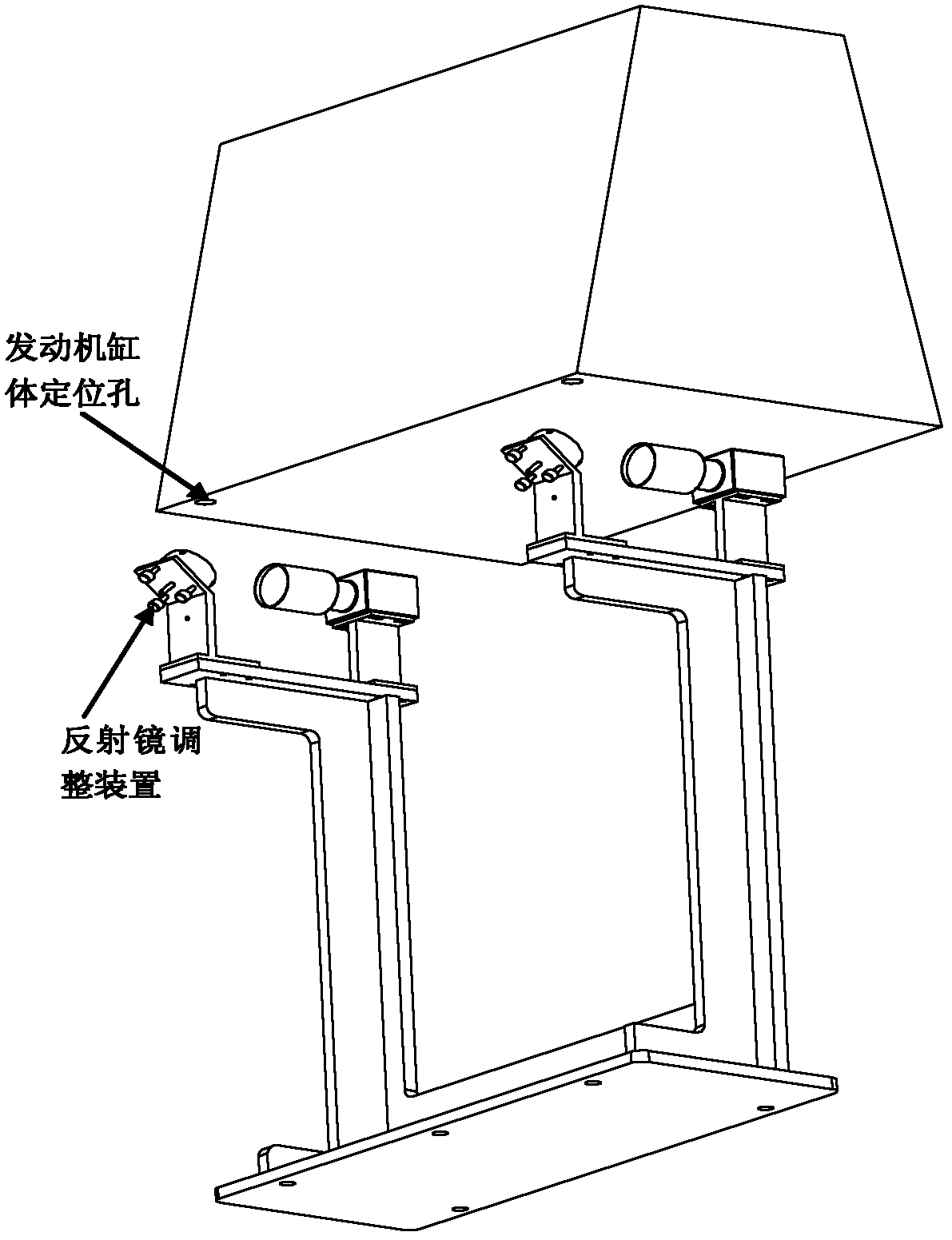

[0023] The visual positioning system designed by the present invention is composed of a double-array CCD positioning camera, an image acquisition card, a calibration target, an optical mirror, a mirror adjustment device, an LED lighting system, and a data processing computer. After the rough positioning of the engine block is completed, a high-brightness LED lighting device is used to illuminate the positioning hole of the engine block, and the image information of the two positioning pin holes of the engine block is obtained through an area array CCD camera and an optical mirror. The computer completes the acquisition of the image information of the calibration target feature hole and the positioning pin hole of the engine cylinder block under test. The center position of the positioning pin hole is extracted by image processing technology, so as to establish the measurement reference of each measured cylinder.

[0024] The positioning system positioning model is attached fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com