Radial bearing static and dynamic excitation device consisting of spring and piezoelectric actuator

A technology of piezoelectric actuator and excitation device, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of low signal-to-noise ratio, unstable installation, and only about 10 μm, so as to improve the recognition accuracy and simplify the bearing test bench structure, reducing the effect of test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

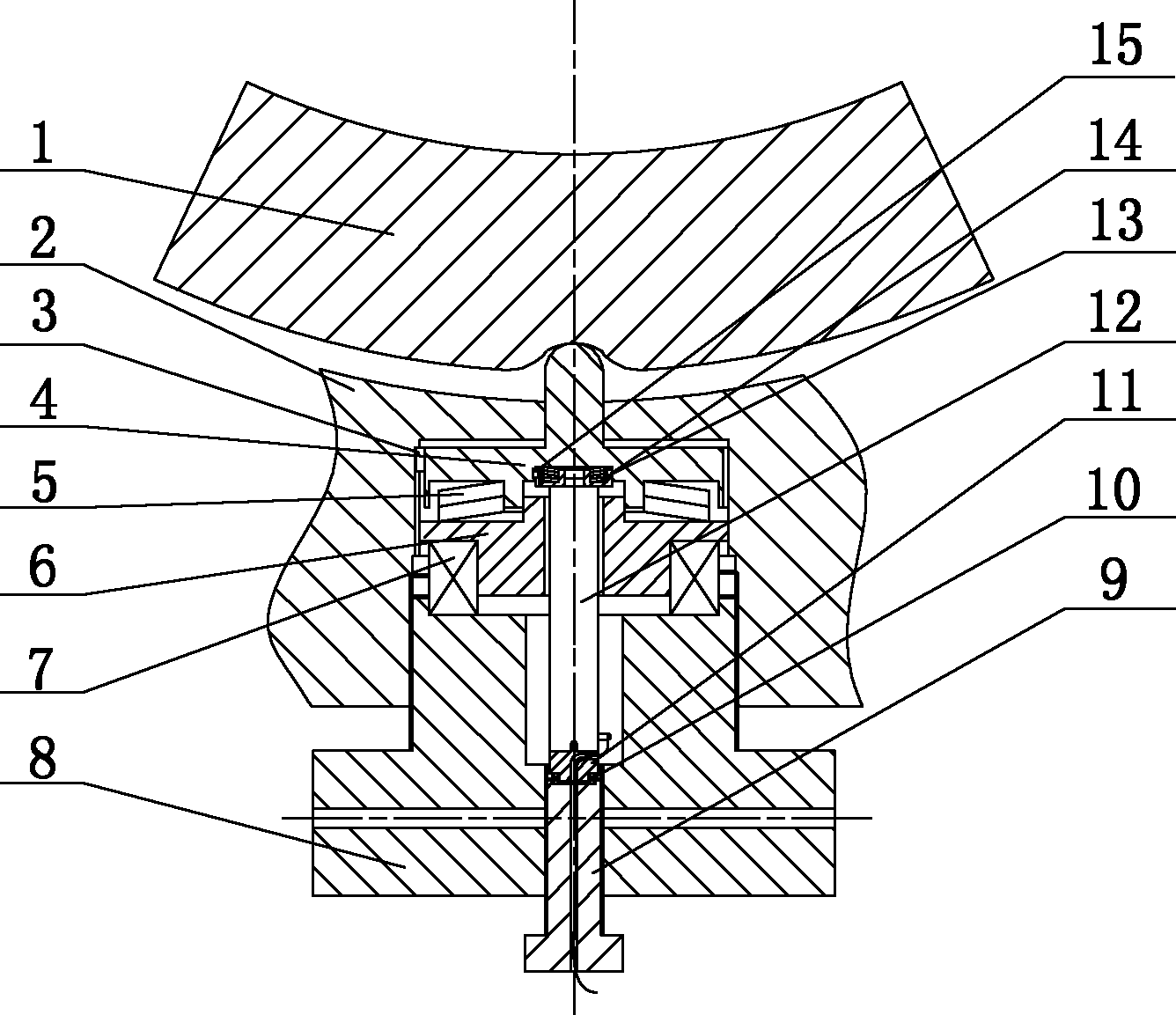

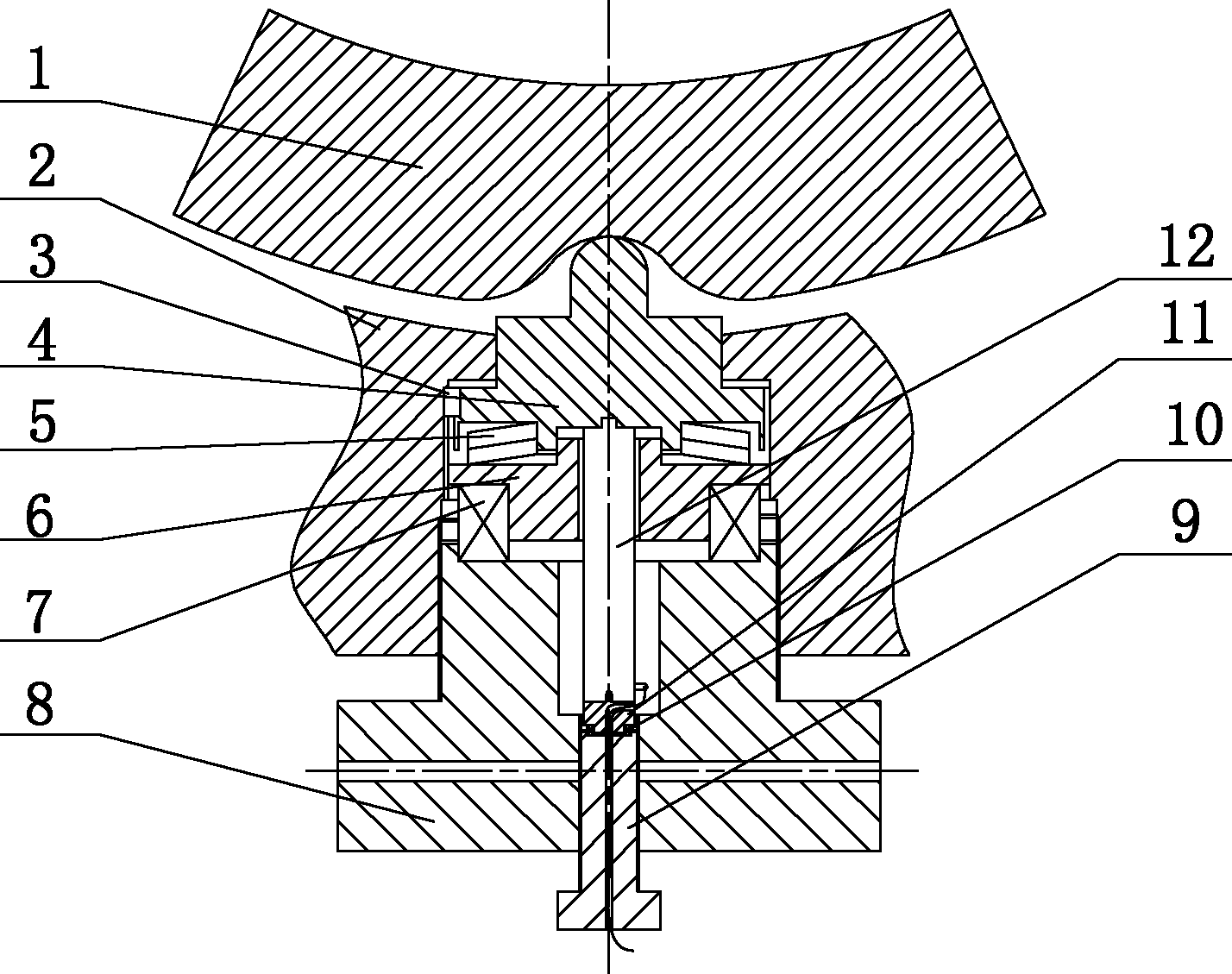

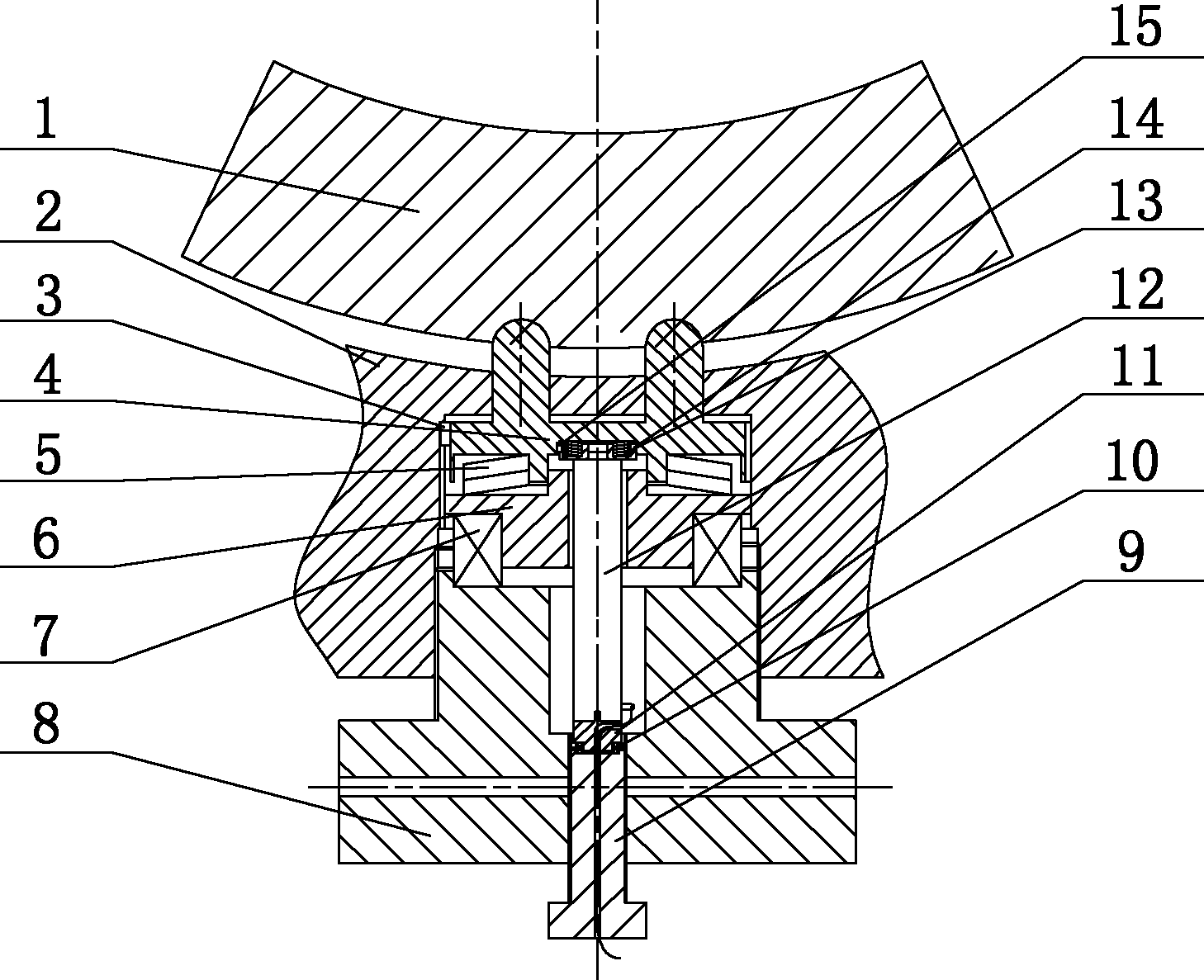

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] See attached figure 1 According to the present invention, the embodiment of the first radial bearing static and dynamic vibration excitation device composed of springs and piezoelectric actuators is the so-called tilting pad radial bearing static and dynamic vibration excitation device. It consists of a static load loading device, a dynamic load excitation device, a lower bearing pad, a cylindrical support block and an afterburner pad. The afterburner tile 1 is a tiltable tile block, and the arc surface of the back groove and the arc surface of the cylindrical ejector rod of the cylindrical support block 4 maintain line contact, and the afterburner tile 1 can wrap around the cylindrical surface The fulcrum of the cylindrical ejector rod of the support block 4 swings freely, and the contact stress can be reasonably controlled by designing the arc surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com