Automatic constant pressure type clamp ring of magnetostrictive guided wave detector

A magnetostrictive and detector technology, applied in the field of snap rings, can solve the problem of uneven pressure of the sensor of the magnetostrictive guided wave detector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The accompanying drawings disclose a specific embodiment of the present invention in a non-limiting manner, which will be further described as follows in conjunction with the accompanying drawings.

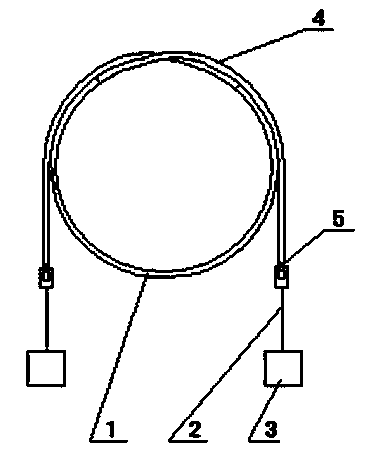

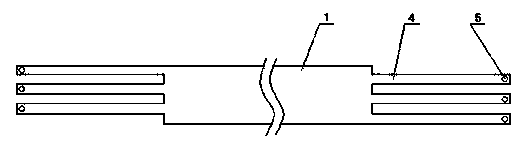

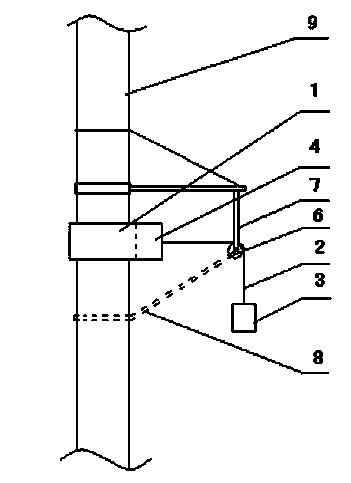

[0013] Referring to the accompanying drawings, the automatic constant pressure type magnetostrictive guided wave detector clasp of the present invention is mainly composed of a stainless steel thin strip 1, a pull cord 2 and a gravity block 3, and the two ends of the stainless steel thin strip 1 are respectively provided with at least 2 separated narrow steel bars 4, such as figure 2 As shown, the end of the narrow steel bar 4 can be provided with a pull hole or a pull ring 5, and the pull hole or the pull ring 5 is connected with one end of the stay rope, and the other end of the stay rope is connected with the gravity block. Its structure is as figure 1 As shown in , this is also a structural schematic diagram of coagulating the sensor of the magnetostrictive guided wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com