Engine exhaust system sealing gasket

A technology for sealing gaskets and exhaust systems, applied in engine components, machines/engines, exhaust devices, etc., can solve the problems of gasket sealing rib fatigue failure, gasket ablation, air leakage, etc., to ensure resilience energy, enhance connection strength, and reduce the risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in conjunction with the embodiments and accompanying drawings.

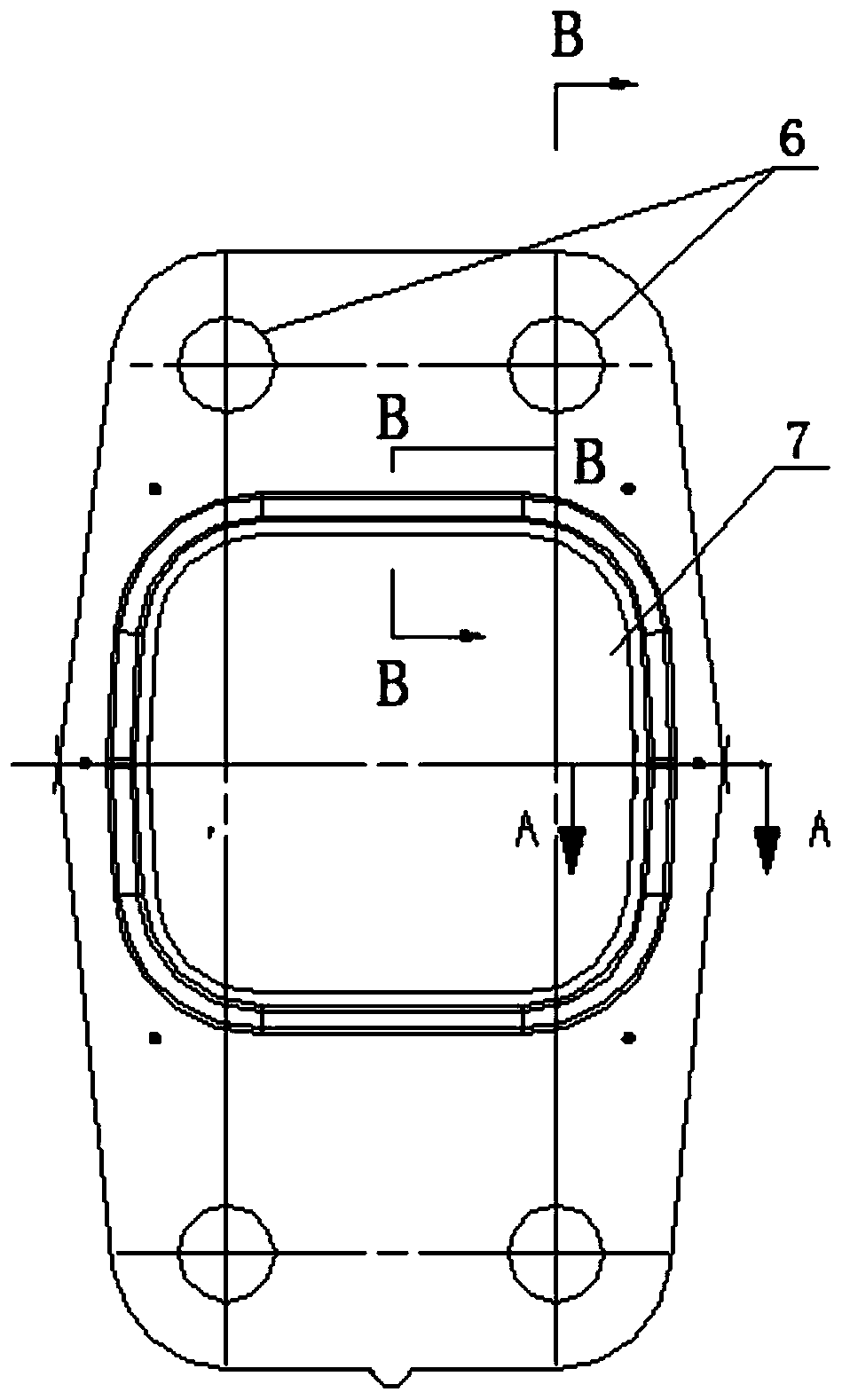

[0033] Such as figure 1 It is a top view of the sealing gasket of the engine exhaust system. The sealing gasket is provided with an exhaust hole 7 and a bolt installation hole 6. The installation bolt passes through the bolt installation hole 6 to connect the sealing gasket and the required sealing parts. Together.

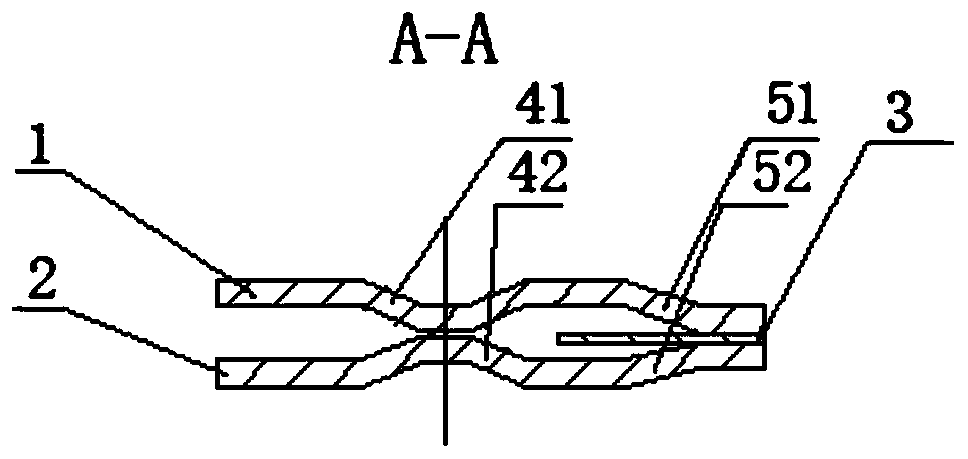

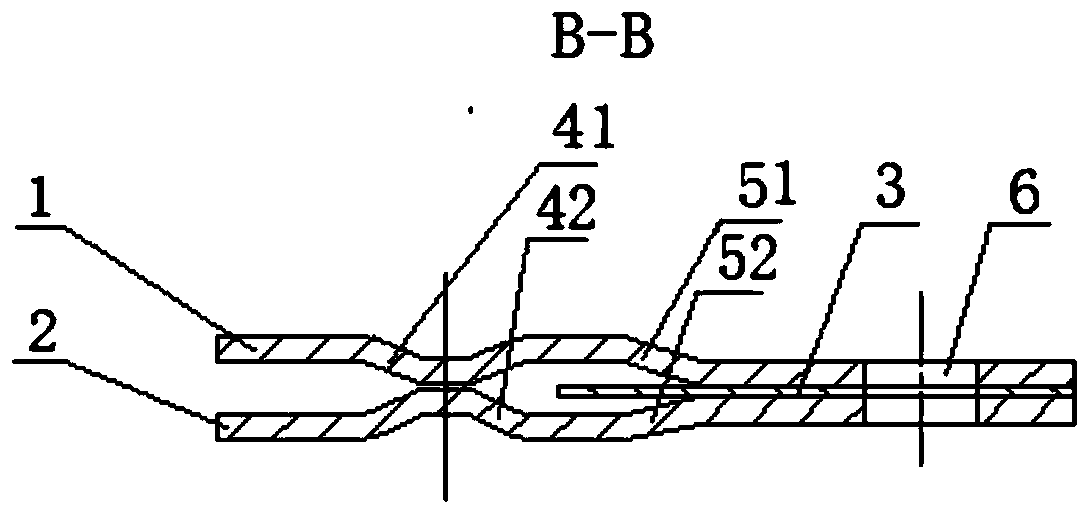

[0034] Such as figure 2 and image 3 , the sealing gasket is composed of the first layer of gasket 1, the limiting layer gasket 3 and the second layer of gasket 2 three layers of gaskets stacked from top to bottom, the first layer of gasket 1, the limiting layer Both the layer gasket 3 and the second layer gasket 2 are metal gaskets. Among them, the first layer of gasket 1 and the second layer of gasket 2 are respectively provided with an upper concav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com