EVA sole and preparation method thereof

A technology of parts by weight and raw materials, which is applied in the field of EVA shoe soles and its preparation, can solve the problems of poor resilience of EVA soles, loss of shock-absorbing performance, poor resilience, etc., to reduce crystallization rate, improve entanglement, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of EVA sole, by weight parts, its raw material composition is as shown in table 1.

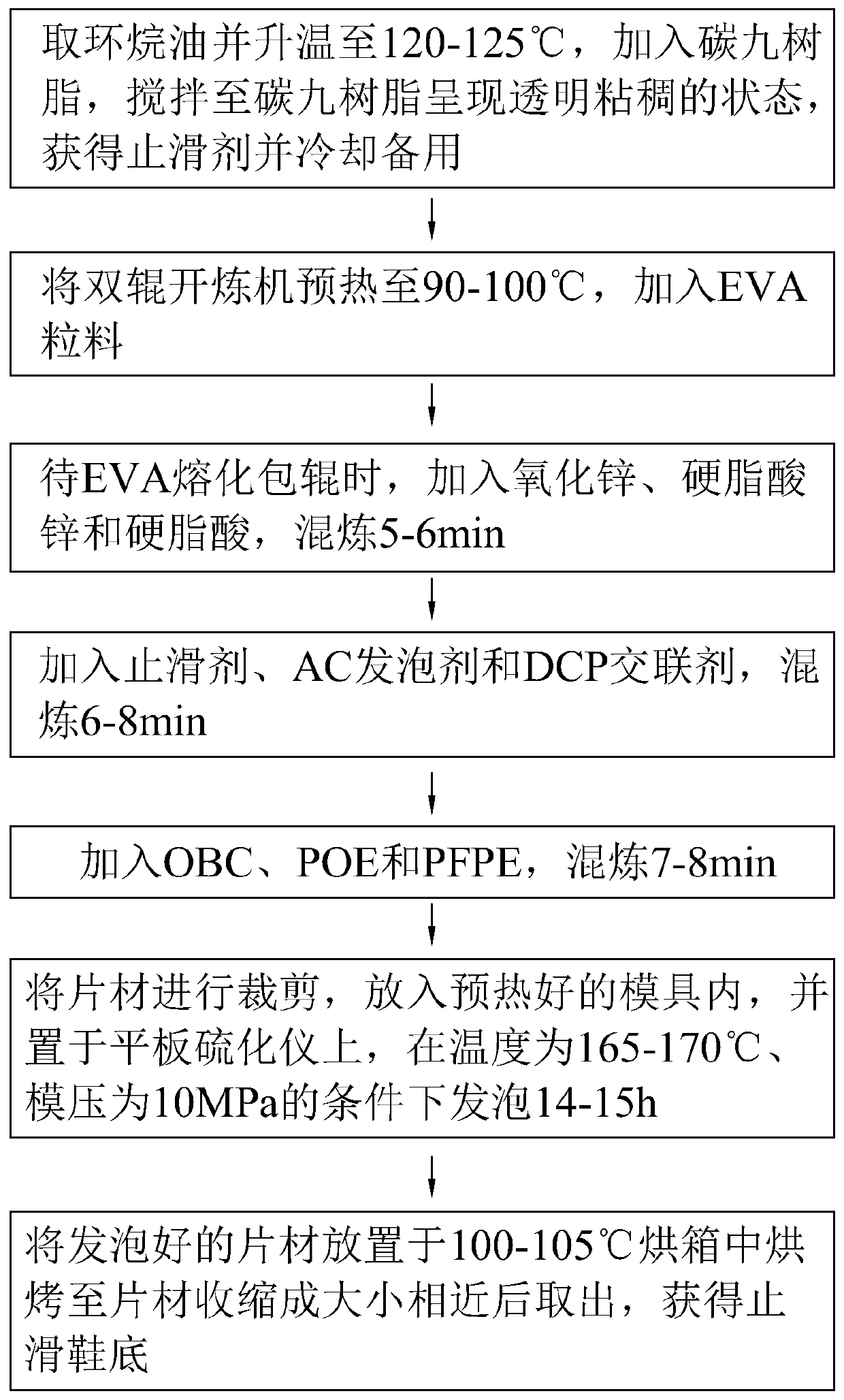

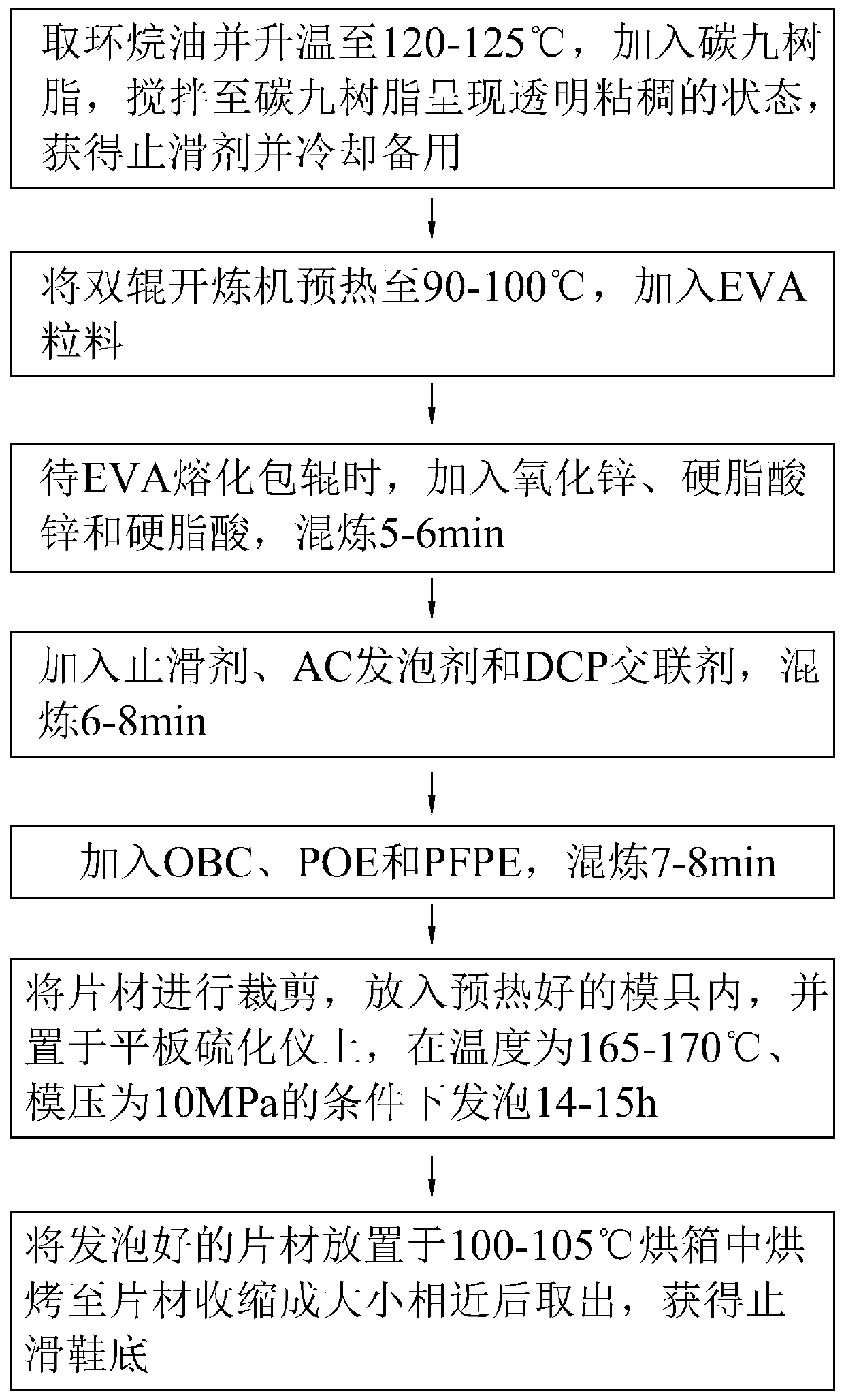

[0049] Such as figure 1 Shown, the preparation method of this sole comprises the following steps:

[0050] S1, take naphthenic oil 4010 and heat up to 120-125°C, add C9 resin, stir until C9 resin is transparent and viscous, obtain anti-slip agent and cool it for later use;

[0051] S2, preheat the double-roll mill to 90-100°C, and add EVA 400W pellets;

[0052] S3, when the EVA is melted and covered with rolls, add zinc oxide, zinc stearate and stearic acid, and knead for 5-6 minutes;

[0053] S4, add anti-slip agent, AC foaming agent and DCP crosslinking agent, and knead for 6-8 minutes;

[0054] S5, add OBC 9530 (Dow in the United States), POE 8137 (Dow in the United States) and PFPE (the degree of polymerization is within 100), knead for 7-8 minutes, and release the tablet;

[0055] S6, cutting the sheet, putting it into a preheated mold, and placing it on a flat vulcanize...

Embodiment 2

[0058] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1.

Embodiment 3

[0060] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com