Photoresist removing method, metal wire etching method and production method of integrated circuit

A technology of integrated circuit and photoresist, which is applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that the photoresist cannot be completely removed, and achieve the effect of avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

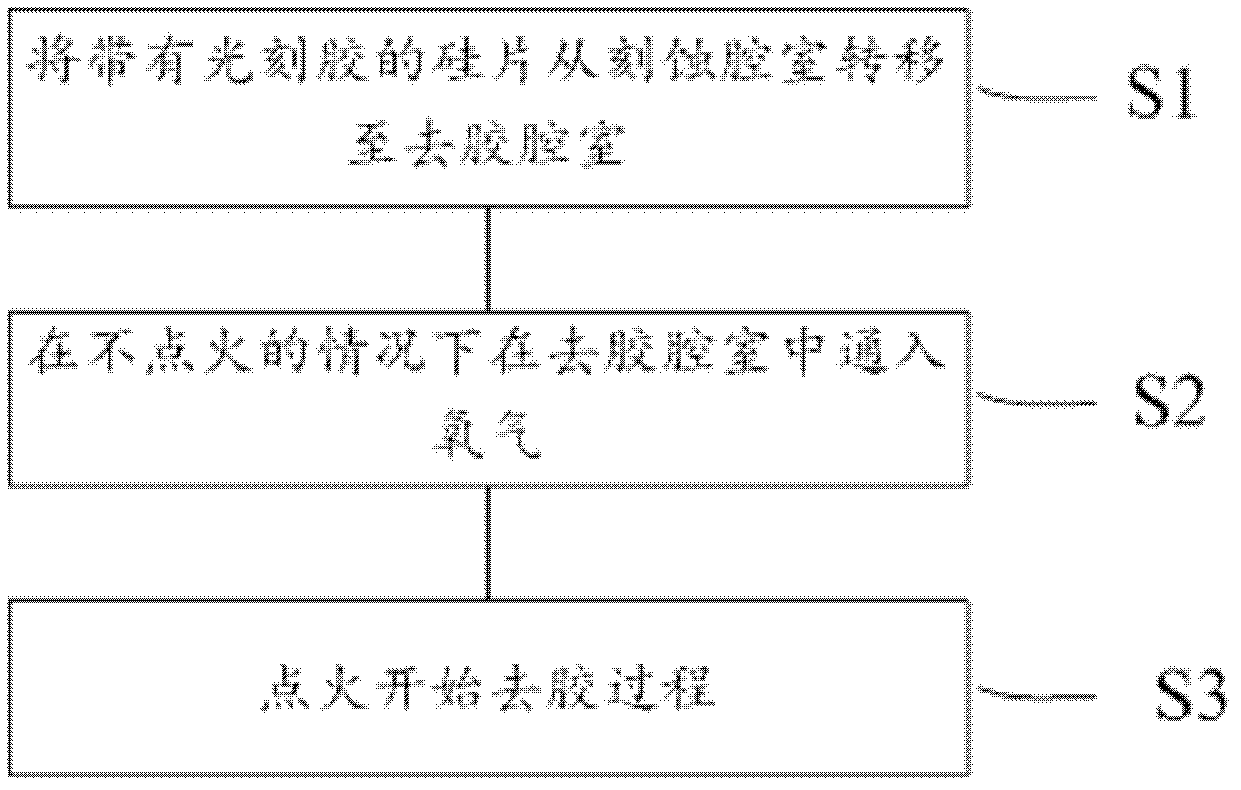

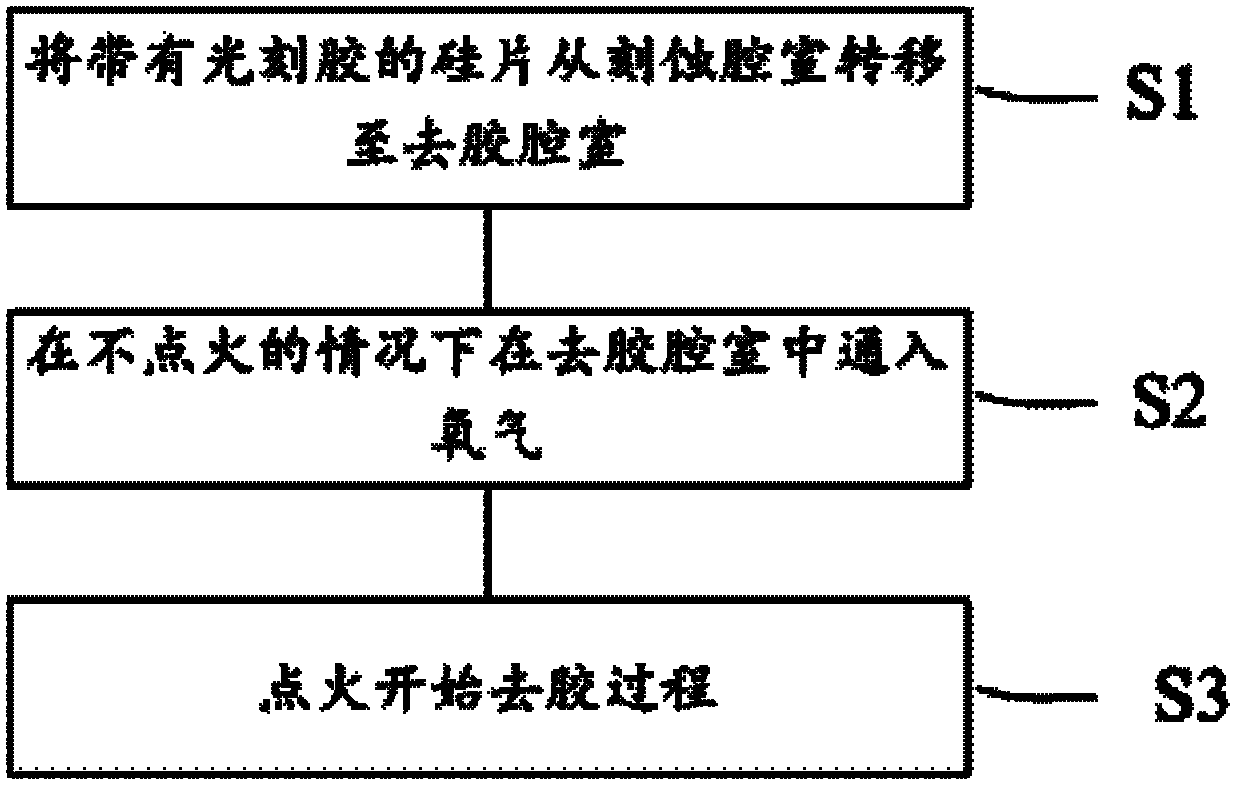

[0018] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0019] The inventors of the present invention have found that in the prior art photoresist removal method, the reason for the formation of photoresist residue is due to the temperature of the silicon wafer below the photoresist when the photoresist is removed in the stripping chamber chamber. The burning rate of the photoresist is not high enough so that part of the photoresist has cured to form a photoresist residue such as photoresist polymer before the photoresist is completely burned out.

[0020] More specifically, the temperature of the stripping chamber is generally 250°C or more higher than the melting point of the photoresist; therefore, when the wafer is transferred from the etch chamber to the stripping chamber, the wafer and stripping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com