Preparation method for double-faced power generation metal wrap through (MWT) solar cell

A technology for solar cells and silicon wafers, applied in the field of solar cells, can solve the problems of increasing process complexity and flow, damage to the mask coverage area, etc., and achieves the effects of being beneficial to cost control, avoiding battery leakage, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

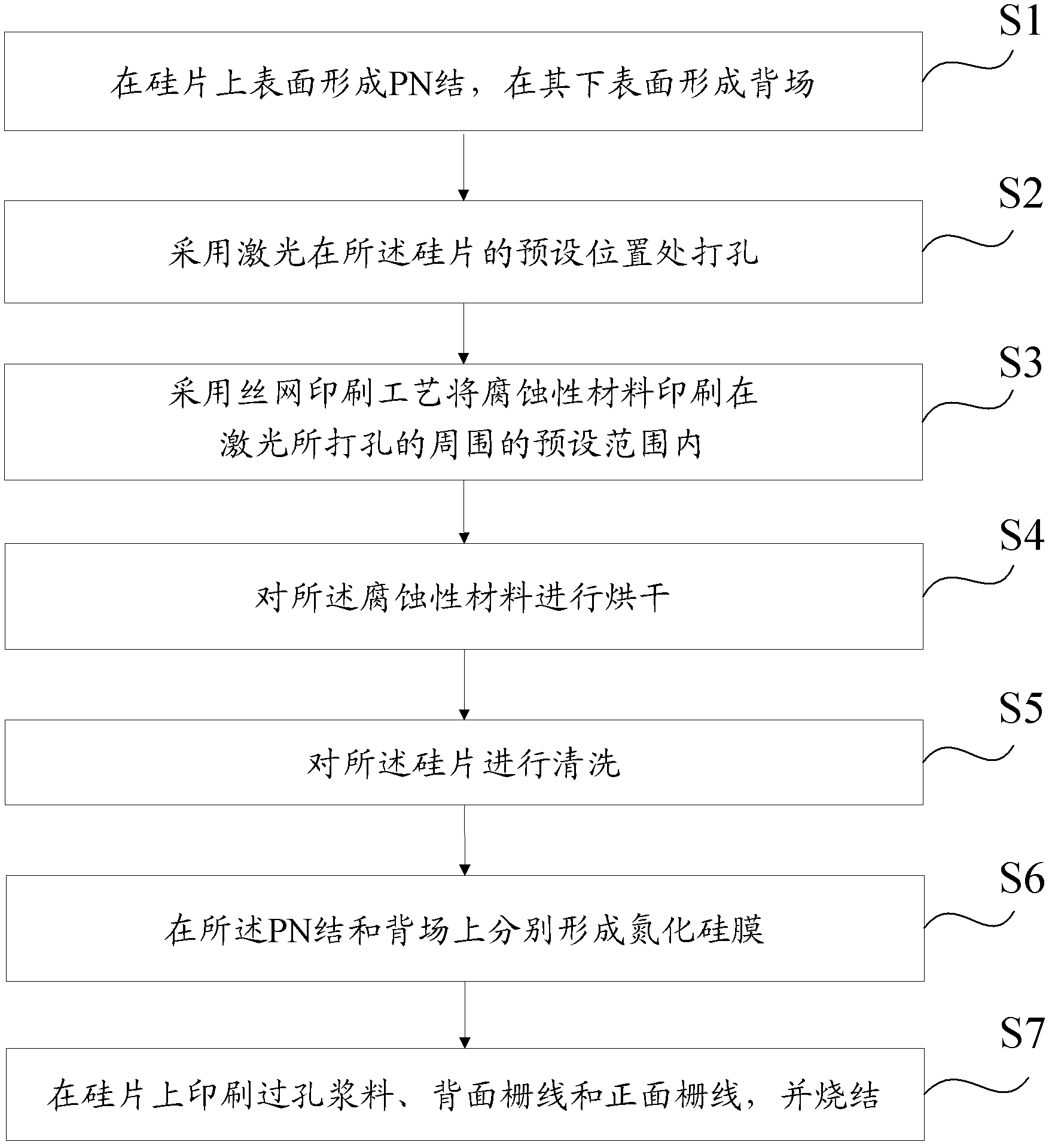

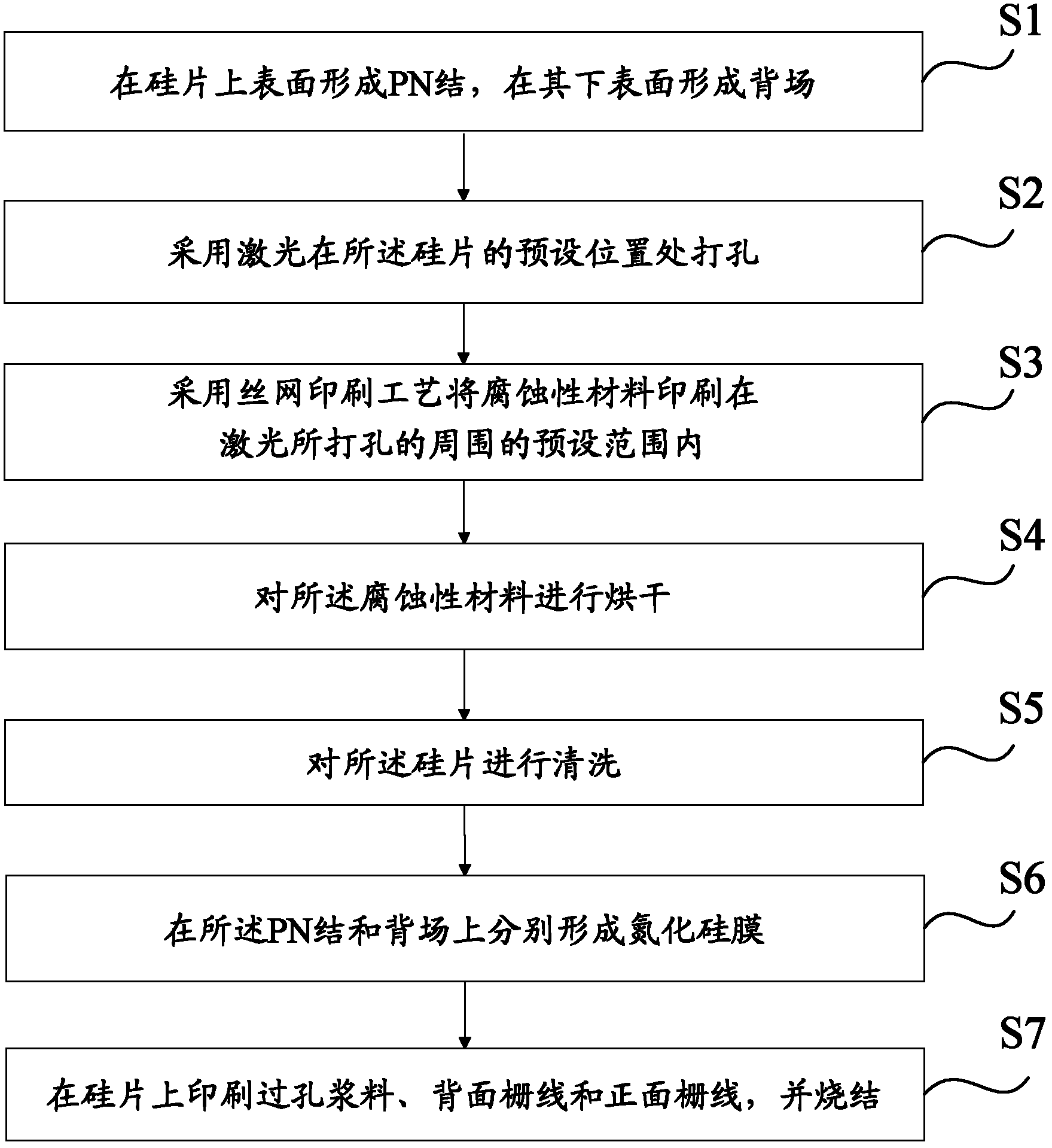

[0027] refer to figure 1 , figure 1 It is a schematic flowchart of a method for preparing a double-sided power generation MWT solar cell provided by an embodiment of the present invention, and the method specifically includes the following steps:

[0028] Step S1: forming a PN junction on the upper surface of the silicon wafer, and forming a back field on the lower surface.

[0029] A PN junction is formed on the upper surface of the silicon wafer through a high-temperature diffusion process, that is, the emitter is formed; and then a highly doped region is formed on the lower surface of the silicon wafer through a diffusion process, that is, the back field.

[0030] Step S2: using a laser to drill holes at preset positions on the silicon wafer.

[0031] The laser used in this step is a pulse laser, which can be a solid pulse laser or a gas pulse laser. The wavelength of the laser can be from 300nm to 1600nm, the pulse length can be from 10ps to 300ns, and the repetition rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com