Insulation central spindle electric conduction slip ring

A technology of conductive slip ring and insulating core, which is applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of conduction, equipment failure, and difficult filling, etc., and achieve simple production process, improved reliability, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

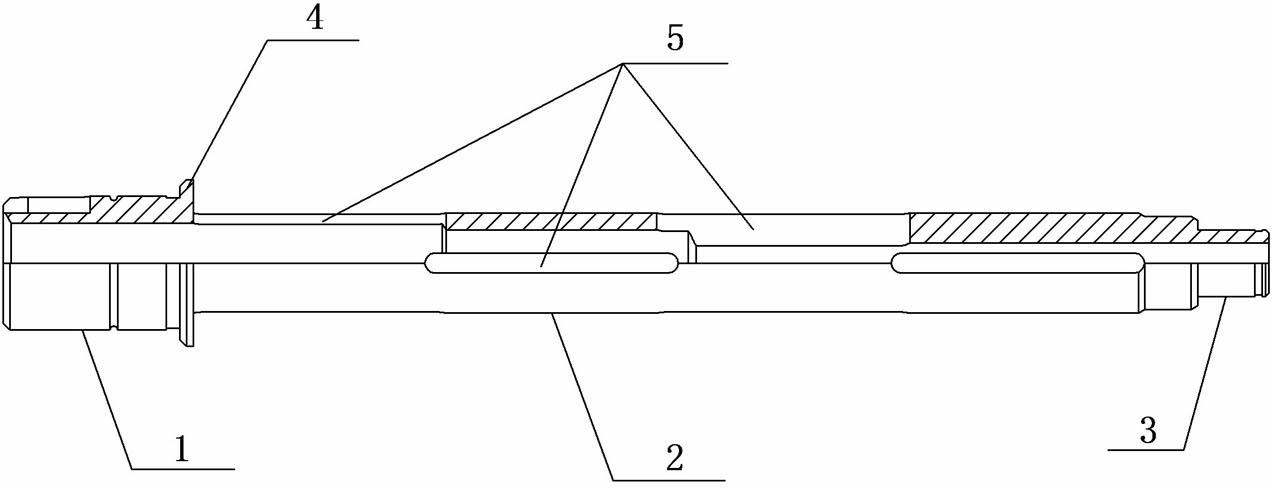

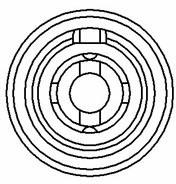

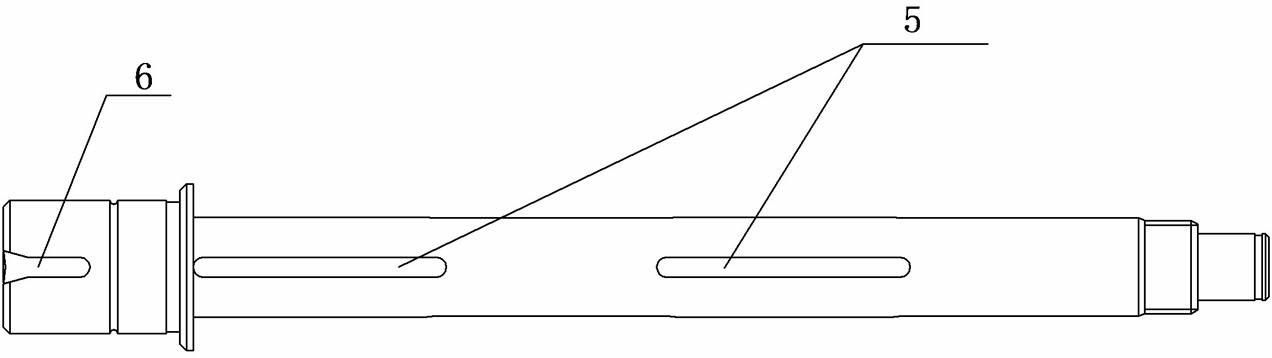

[0023] see Figure 1~Figure 6 , an insulating mandrel conductive slip ring, including a rotor part and a stator part, brush rings 8 and insulating spacers 10 are alternately installed on the insulating mandrel 7 to form the rotor part of the conductive slip ring. Brushes 9 and brush spacers 11 are alternately installed on the brush fixing rod 15 of the slip ring base 12, and the extension spring 16 between the brushes 9 constitutes the stator part of the conductive slip ring. A bearing 14 is provided between the insulating mandrel 7 and the slip ring base 12, and an end cover 13 is connected to one end of the conductive slip ring, wherein the insulating mandrel 7 is made of insulating material.

[0024] Among them, the shaft body of the insulating mandrel 7 is composed of the front section 1 of the shaft body, the middle section 2 of the shaft body and the rear section 3 of the shaft body. The diameter is greater than the diameter of the middle section 2 of the shaft body. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com