High-concentration oxygen-dissolving apparatus using ultrasonic waves

一种超声波、高浓度的技术,应用在溶解、溶解、运输和包装等方向,能够解决不能溶解氧气、长时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

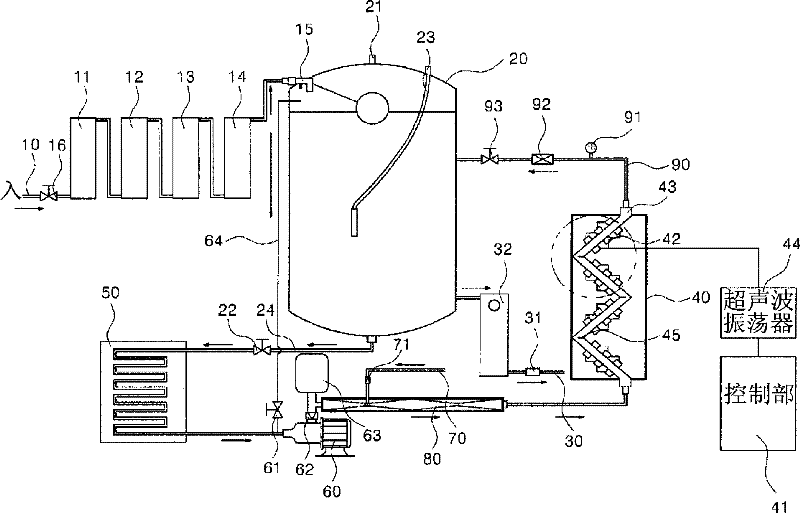

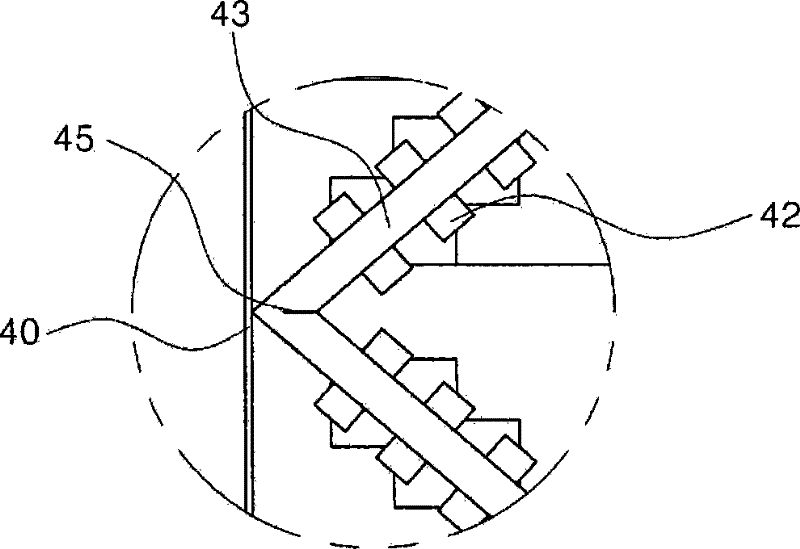

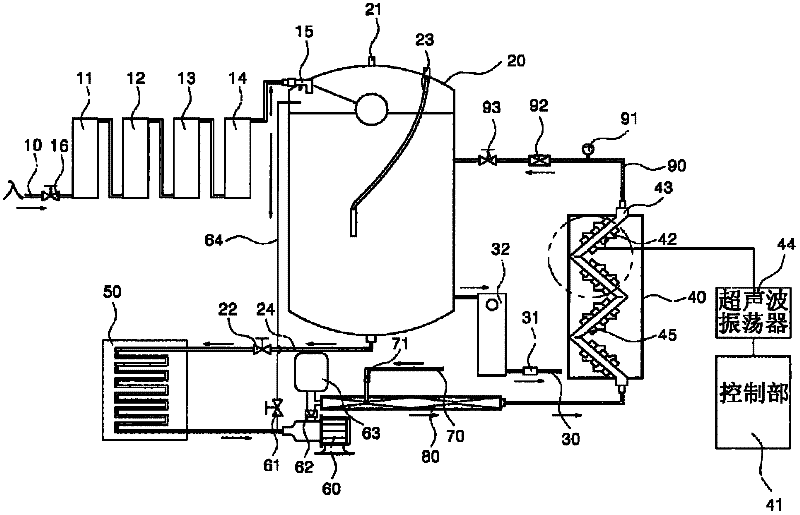

[0018] The present invention provides a device for dissolving high-concentration oxygen into a liquid, which is characterized in that it includes: an inflow port 10 for inflowing into the liquid, and is provided with an inflow regulating valve 16; a sedimentation filter 11 for filtering through the The foreign matter contained in the liquid that flows into the inlet 10; the pre-carbon filter 12, which is connected to the sediment filter 11, and filters harmful chemicals contained in the liquid; the UF membrane filter 13, which is connected to the The front carbon filter 12, and filters the impurities dissolved in the liquid; the rear activated carbon filter 14, which is connected to the UF membrane filter 13, and filters gas components and odor components; the injection port 15, which Connected to the post activated carbon filter 14, and inject the liquid into the storage tank 20 for storing the liquid, the injection port is provided with a water level regulator for predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com