Combustion plate

A combustion plate and burner technology, applied in the direction of burners, burners, combustion methods, etc., can solve the problems of increased passage resistance of combustion plates, increased blower burden, increased blower noise, etc., to reduce passage resistance and opening ratio The effect of increasing and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

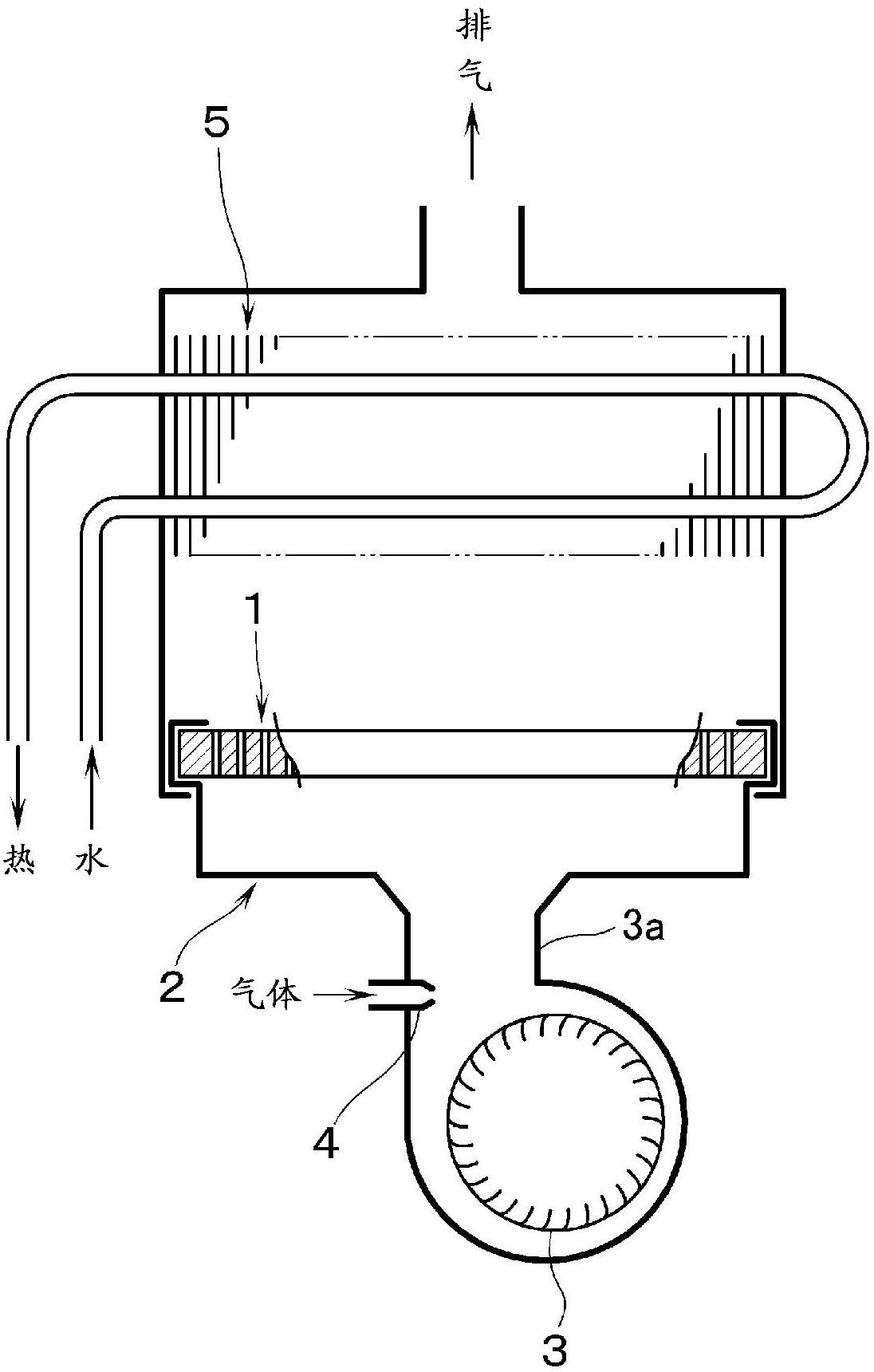

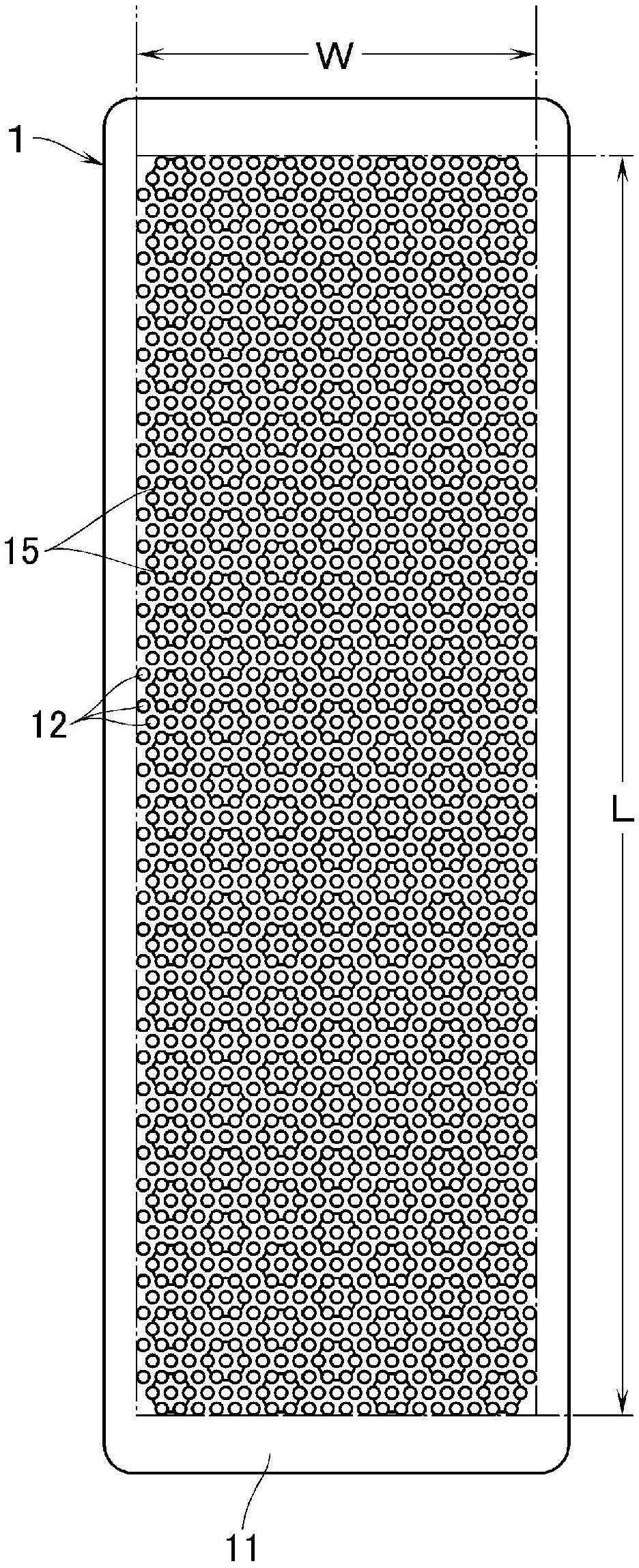

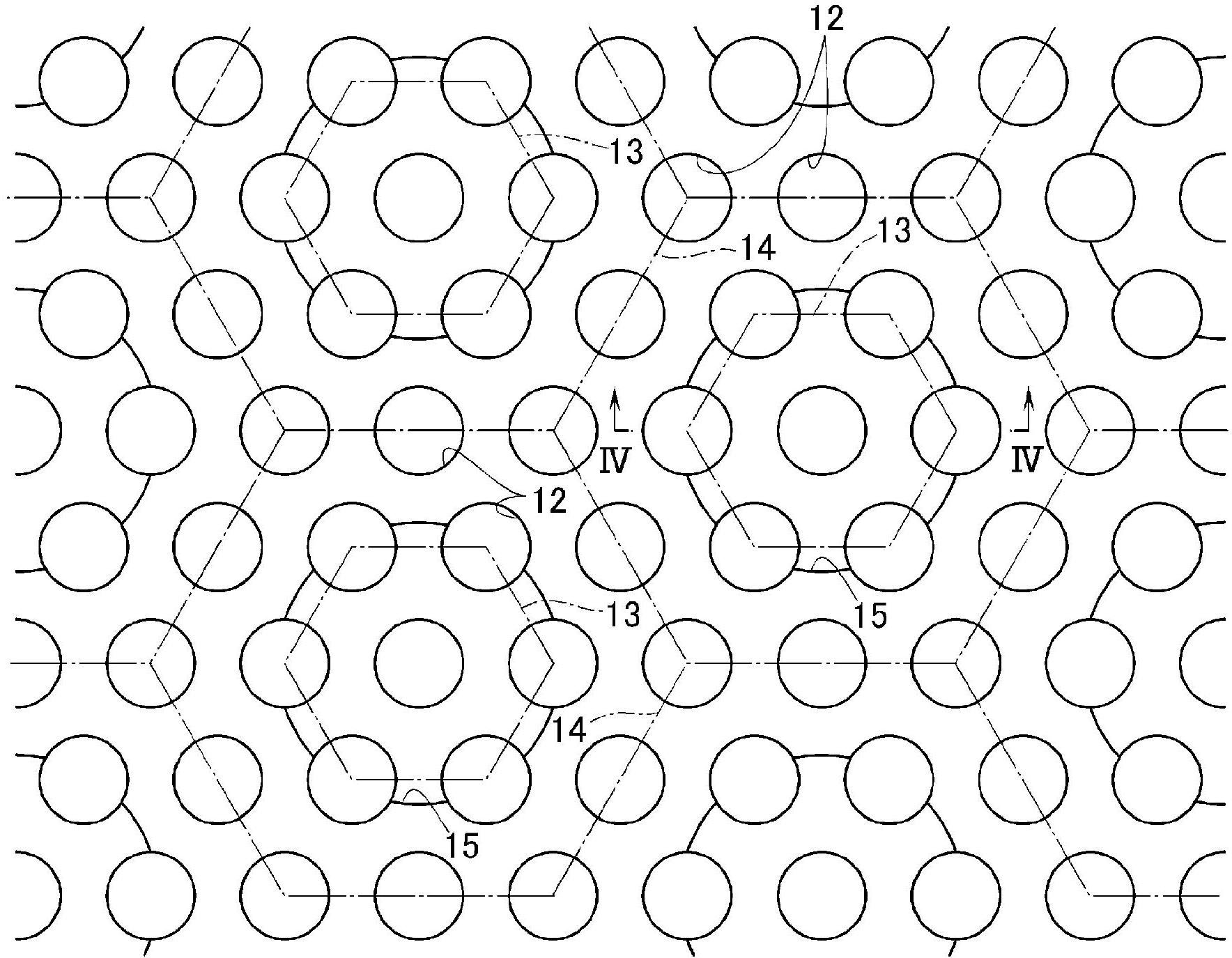

[0032] figure 1 A heat source machine for hot water supply or heating including a totally aerated combustion burner (totally aerated combustion burner) 2 using a combustion plate 1 is shown. The blower 3 is connected to the burner 2 via the ventilation passage 3a. Furthermore, a gas nozzle 4 for injecting fuel gas is provided in the ventilation passage 3a. Furthermore, the premixed gas of the primary air supplied from the blower 3 and the fuel gas injected from the gas nozzle 4 is sprayed and burned through the combustion plate 1, and the heat exchanger 5 for supplying hot water or heating is heated by the combustion gas. .

[0033] Here, the blower 3 is controlled so that the amount of primary air is larger than the stoichiometric air amount required for complete combustion of the fuel gas. Therefore, the premixed gas having an excess air ratio (primary air volume / stoichiometric air volume) greater than 1 is injected through the combustion plate 1 to perform primary total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com